Poly-anthraquinone sulfide and Fe3O4 composite material as well as preparation method and application thereof

A technology of sulfide and polyanthracene, which is applied in the direction of active material electrodes, structural parts, alkaline storage batteries, etc., can solve the problems of poor cycle stability of electrodes, structural changes of electrode materials, and low rate performance, so as to achieve low raw material prices and improve electrical conductivity. Good effect on performance, specific capacity and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a kind of polyanthraquinone sulfide and Fe 3 O 4 The preparation method of the composite material comprises the following steps:

[0033] Step 1. Under a protective atmosphere, the Fe 3 O 4 Nanoparticles and 1,5-dichloroanthraquinone are stirred and dispersed into methylpyrrolidone (NMP) to obtain a precursor solution;

[0034] Step 2, adding sodium sulfide to the above-mentioned precursor solution;

[0035] Step 3, raising the temperature of the reaction system to carry out the reaction, cooling to room temperature after the reaction is completed, washing and drying the product to obtain polyanthraquinone sulfide (PAQS) and Fe 3 O 4 composite material.

[0036] Specifically, in the above step 1, considering Fe 3 O 4 Excessive molar ratio of nanoparticles to 1,5-dichloroanthraquinone will lead to poor structural stability of the PAQS embedded layer, thereby affecting the cycling stability of the electrode, while too small ratio will lead t...

Embodiment 1

[0057] This embodiment provides a kind of polyanthraquinone sulfide and Fe 3 O 4 A method for preparing a composite material, comprising:

[0058] Under the protection of argon, 1.0 g Fe 3 O 4 Nanoparticles and 2.77g of 1,5-dichloroanthraquinone were dispersed in 30ml of methylpyrrolidone, stirred for 30 minutes to prepare a uniform precursor solution; 2.40g of sodium sulfide nonahydrate was added to the above precursor solution, and the solution was heated at 200°C. Under the temperature, the reaction was stirred for 14 h; the reaction product was filtered and washed with deionized water at 70 °C for 3 times, and then filtered and washed with acetone for 3 times. The obtained sample was vacuum-dried at 120 °C for 12 h to obtain polyanthraquinone sulfide and Fe 3 O 4 composite material. Na 2 S·9H 2 The molar ratio of O to 1,5-dichloroanthraquinone was 1:1.

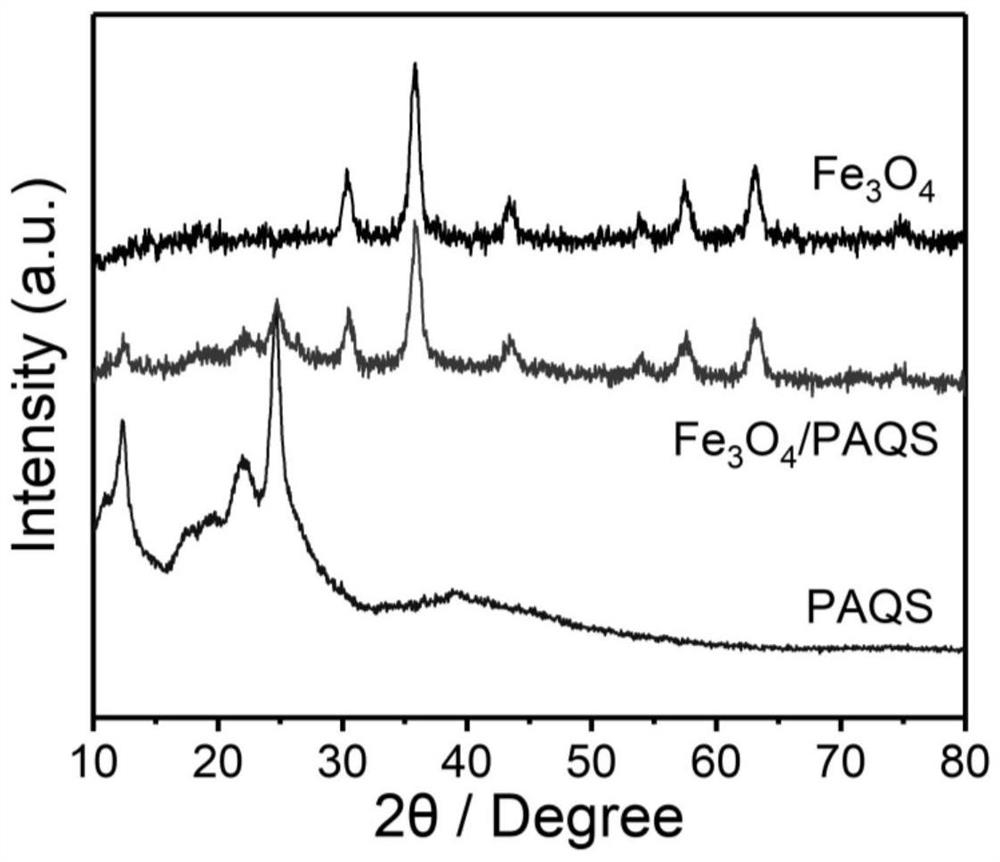

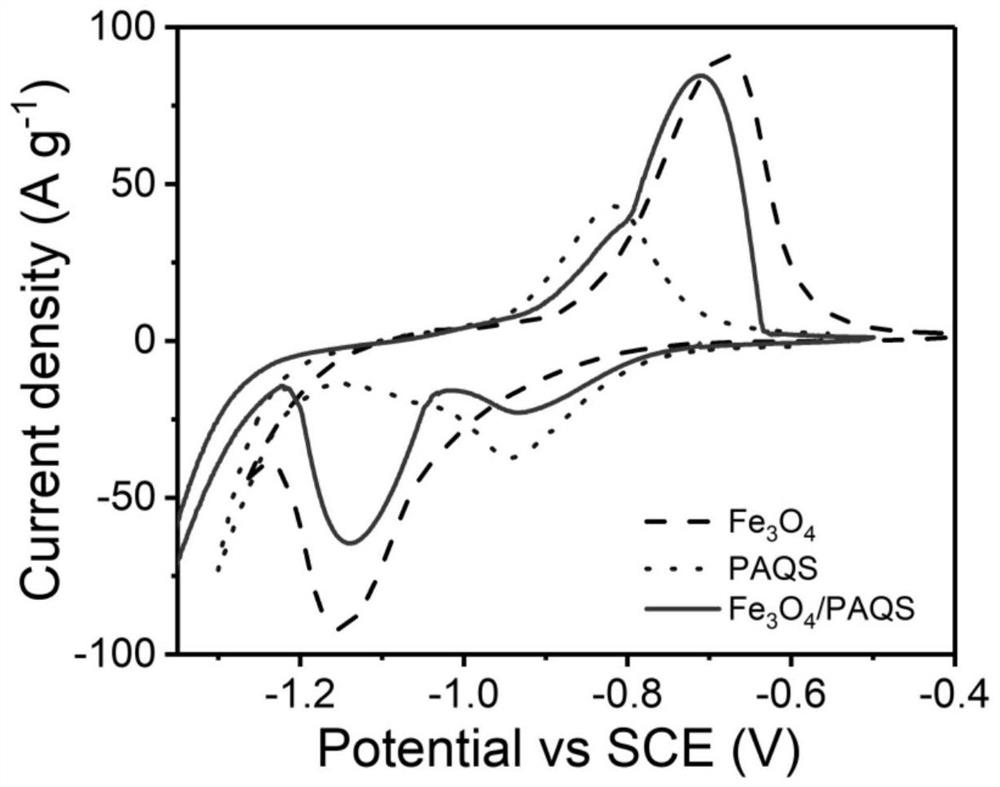

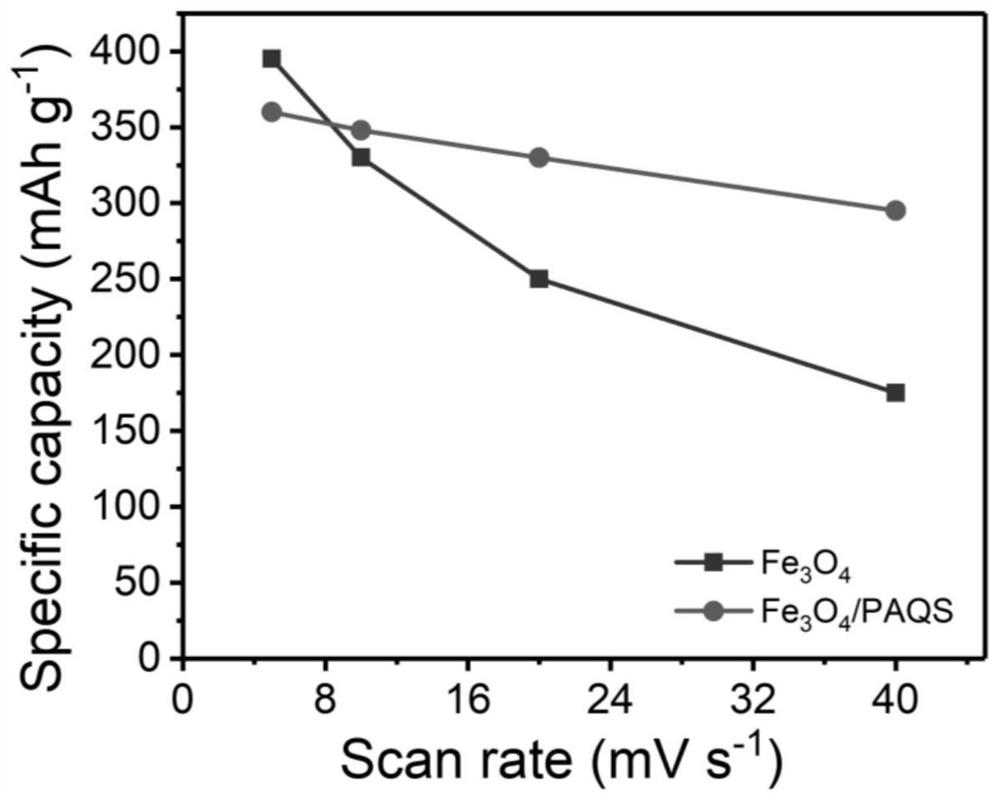

[0059] tested, figure 1 The polyanthraquinone sulfide (PAQS) and Fe prepared in Example 1 of the present invent...

Embodiment 2

[0064] This embodiment provides a kind of polyanthraquinone sulfide and Fe 3 O 4 The preparation method of the composite material comprises: under the protection of argon, 1.0g Fe 3 O 4 Nanoparticles and 2.22g of 1,5-dichloroanthraquinone were dispersed in 30ml of methylpyrrolidone and stirred for 25 minutes to prepare a uniform precursor solution; 1.92g of sodium sulfide nonahydrate was added to the above precursor solution, and the solution was heated at 210°C. At the temperature, the reaction was stirred for 15h. The reaction product was filtered and washed with deionized water at 60 °C for three times, and then filtered and washed with acetone for three times. The obtained sample was vacuum-dried at 110 °C for 15 h to obtain polyanthraquinone sulfide and Fe. 3 O 4 composite material.

[0065] After testing, the polyanthraquinone sulfide prepared in this example and Fe 3 O 4 Polyanthraquinone sulfide (PAQS) and Fe were detected in the composite material 3 O 4 X-ray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com