Welding procedure of ESP continuous casting stainless steel crystallizer water tank

A stainless steel and crystallizer technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult welding deformation control, small welding deformation, and reduced assembly process, so as to improve the efficiency of turning back and forth and improve the quality , The effect of shortening the welding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The welding process of the ESP continuous casting stainless steel mold water tank provided by the present invention will be further described below with reference to specific embodiments.

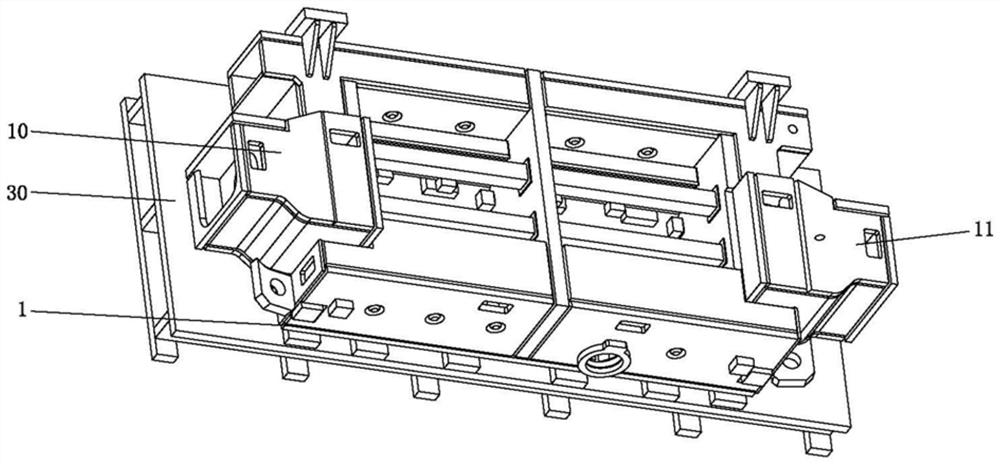

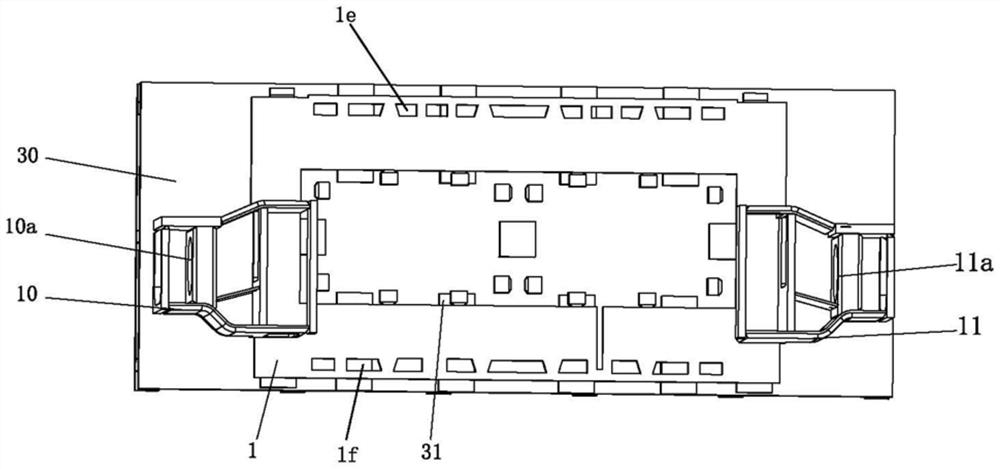

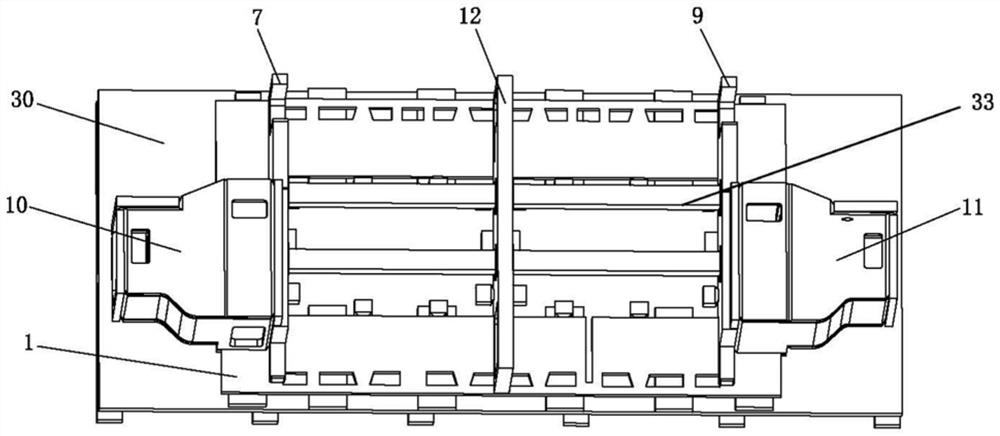

[0032] like Figures 1 to 9 As shown in the welding process of the ESP continuous casting stainless steel mold water tank of the present invention, ESP refers to the production process of headless strip steel. In this solution, all materials of the ESP continuous casting stainless steel mold water tank are stainless steel, and the specific welding process as follows:

[0033] like Figure 2 to Figure 3 as well as Figure 8 As shown, first the first head 10 and the second head 11 are obtained by welding, and then the bottom plate 1 is welded to several first spacers 31 on the platform 30, wherein the platform 30 is first welded with the bottom bracket 32, and then the The first pads 31 are respectively welded to the corresponding positions of the platform 30 to form a platform tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com