Cutter bar of modular cutter and modular cutter

A modular and cutting tool technology, which is applied to the accessories of tool holders, tools for lathes, manufacturing tools, etc., can solve the problems of difficult control of tool dynamic balance, tool breakage, affecting tool processing life and processing quality, etc., to improve Processing life and processing quality, satisfaction of rigidity and strength, and effect of improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

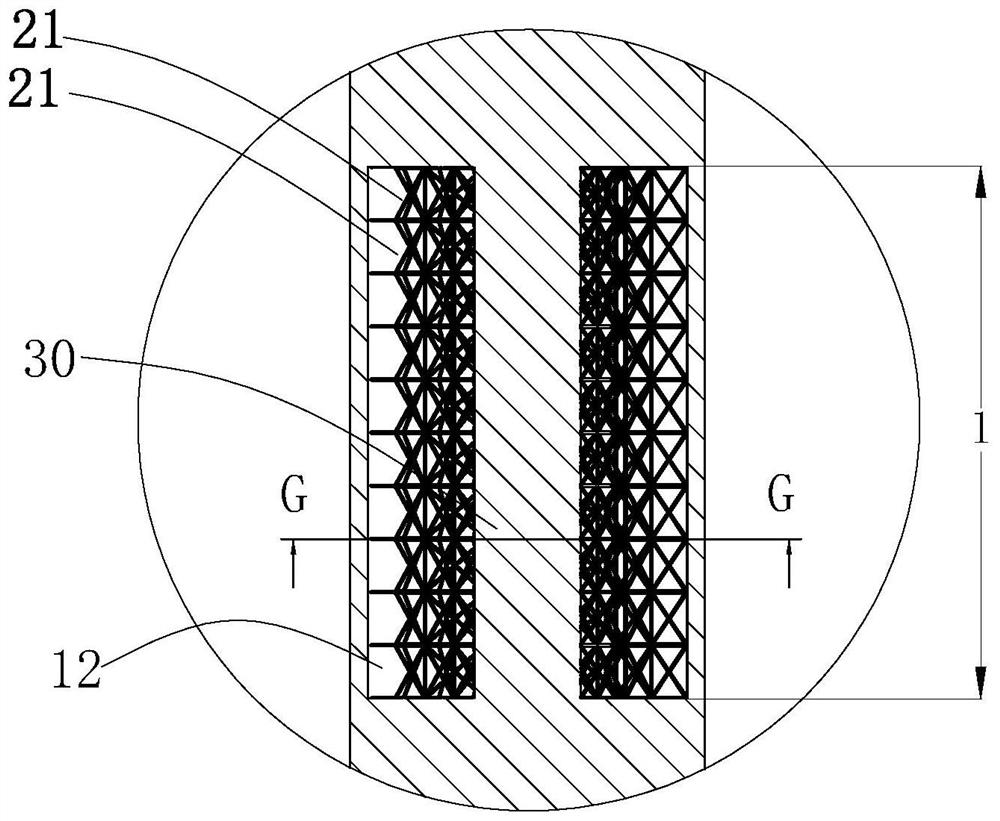

[0058] A tool holder and a modular tool for a modular tool, the main structure of which is the same as that of the first embodiment, the difference is: see Figure 11 , the diameter of the maximum circumscribed circle of the load-bearing structure 30 gradually increases from the end of the locking portion 11 to the other end of the rod body 10 , that is, the end of the tool handle.

[0059] Since different parts of the cutter bar bear different bending moments during machining, the farther away from the locking portion 11 of the bar body 10, the greater the bending moment, and the higher the strength and rigidity requirements are. In this embodiment, by reasonably setting the maximum circumscribed circle diameter of the section of the load-bearing structure 30 at different positions of the rod body 10 , the weight of the tool is further reduced while satisfying the structural strength and rigidity requirements at different positions.

[0060] In this embodiment, since the maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com