Spraying process and formula of reinforced high-flow anti-oxidation anti-fouling coating on inner wall of corrugated pipe

A bellows, high-flow technology, used in coatings, devices for coating liquids on the surface, etc., can solve the problems of wear on the inner wall of the bellows, the inner wall of the bellows cannot be effectively protected, and the corrosion of corrosive substances. Effects of wear and corrosion, good surface anti-fouling, excellent chemical and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

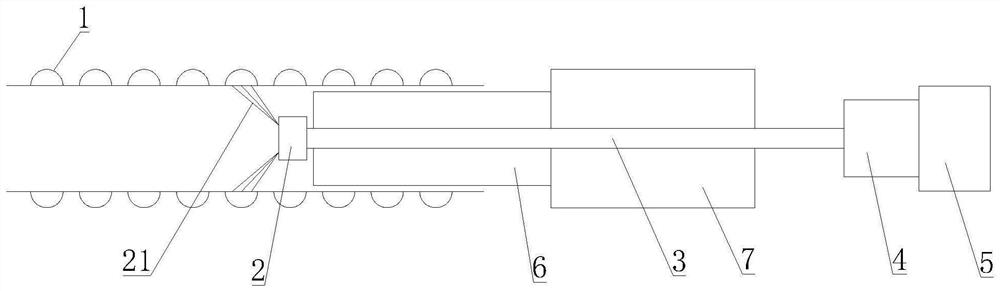

[0022] like figure 1 As shown, the present invention proposes a spraying process for enhancing the high-flow anti-oxidation and anti-fouling coating on the inner wall of the bellows, including the following steps:

[0023] S1. Add polyurethane paint in paint storage tank 5;

[0024] S2. Pass the paint pipe 3 through the extruder head 7 and the water jacket 6;

[0025] S3, move the bellows 1 to the outer circumference of the water jacket 6;

[0026] S4, start the spraying machine 4, the spraying machine 4 extracts the polyurethane paint from the paint storage tank 5, and transports the polyurethane paint to the nozzle 2 through the paint pipeline 3, and the nozzle 2 sprays the polyurethane paint in the form of a paint spray 21 to the inner wall of the bellows 1, A layer of polyurethane film coating is formed on the inner wall of the bellows 1 .

[0027] The polyurethane coating concentration, nozzle 2 gap and spraying pressure are all controllable; by controlling the polyure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com