Rabdosia eriocarpa heat-clearing and sore-throat-relieving tablet and preparation method thereof

A technology of Mao'exiang Chacai and Pharynx-relieving Tablets, which is applied in the field of preparation of Mao'exiangchacai Qingre-pharynx Tablets and Mao'exiang Chacai Qingre-pharynx Tablets. The effect of material fluidity and shortened onset time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

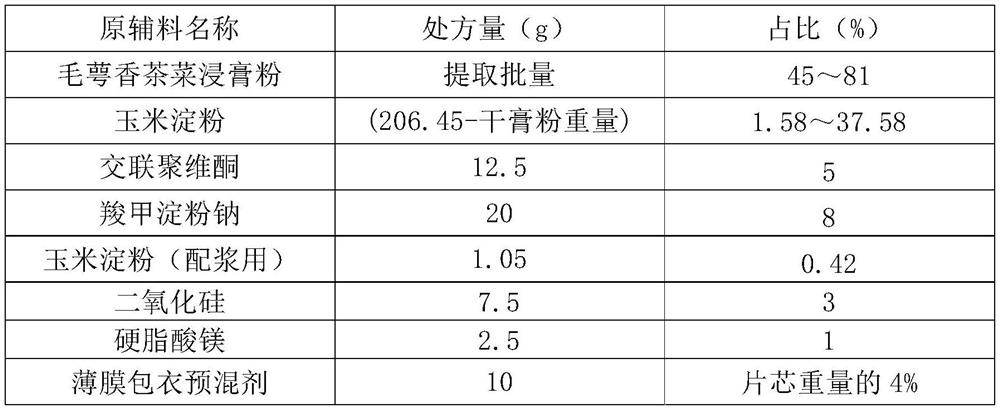

[0042] The present embodiment discloses a calyx fragrant tea and herbal heat-clearing and pharyngeal tablet, comprising a tablet core and a film-coating premix for wrapping the tablet core, and the tablet core comprises the following components in mass percentage: 45-81%, corn starch 1.58-37.58%, crospovidone 5%, sodium starch glycolate 8%, corn starch 0.42% for pulping, silicon dioxide 3%, magnesium stearate 1%; film coating The coating premix is calculated by 3-5% of the mass of the tablet core;

[0043] Among them, the film coating premix is calculated as 4% of the mass of the tablet core.

[0044] The film-coating premix is a stomach-dissolving film-coating premix.

[0045] In order to facilitate those skilled in the art to further understand the present invention, the present invention will be further described below in conjunction with specific preparation examples.

[0046] The Maocalyxxiangchacaiqingreliyan tablet provided by the invention redesigns and optimiz...

specific Embodiment 1

[0074] (1) Granulation:

[0075] ①Preparation of adhesive: Take corn starch (for slurrying), add appropriate amount of warm water to wet, add boiling water to 17.5g, stir to make 6% starch slurry, cool to room temperature, add purified water to 17.5g before use g, after stirring evenly, set aside.

[0076] ② Add 45 parts of Calyx calyx tea extract powder, 37.58 parts of corn starch, 5 parts of sodium carboxymethyl starch, and 5 parts of crospovidone into the rapid mixing granulator, pre-mixed for 300s (stirring 20Hz), here Parts can be understood as a percentage by mass.

[0077] 3. After premixing, turn on the stirring speed of 20Hz, and slowly and evenly add 6% cornstarch slurry into the rapid mixing granulator from the pulping port;

[0078] ④ After adding slurry, granulate for 180s (stir 20Hz, granulating knife 20Hz), discharge and load on tray.

[0079] ⑤ Set the oven temperature to 60°C, and dry to a particle moisture content of 2.0% to 5.0%.

[0080] ⑥Use a swinging...

specific Embodiment 2

[0090] (1) Granulation:

[0091] ①Preparation of adhesive: Take corn starch (for slurrying), add appropriate amount of warm water to wet, add boiling water to 17.5g, stir to make 6% starch slurry, cool to room temperature, add purified water to 17.5g before use g, after stirring evenly, set aside.

[0092] ② Add 81 parts of Calyx calyx tea extract powder, 1.58 parts of corn starch, 5 parts of sodium carboxymethyl starch, and 5 parts of crospovidone into the rapid mixing granulator, and pre-mix for 300s (stir 20Hz).

[0093] 3. After premixing, turn on the stirring speed of 20Hz, and slowly and evenly add 6% cornstarch slurry into the rapid mixing granulator from the pulping port;

[0094] ④ After adding slurry, granulate for 180s (stir 20Hz, granulating knife 20Hz), discharge and load on tray.

[0095] ⑤ Set the oven temperature to 60°C, and dry to a particle moisture content of 2.0% to 5.0%.

[0096] ⑥Use a swinging granulator to install a 14-mesh sieve for granulation.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com