Method for fully filling uneven gap between cabinet body and wall surface

A cabinet and gap technology, which is used in the field of fully filling the uneven gap between the cabinet and the wall, can solve the problems of the limited size of the soft rubber strip, the small deformable range, and the difficulty in pushing furniture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

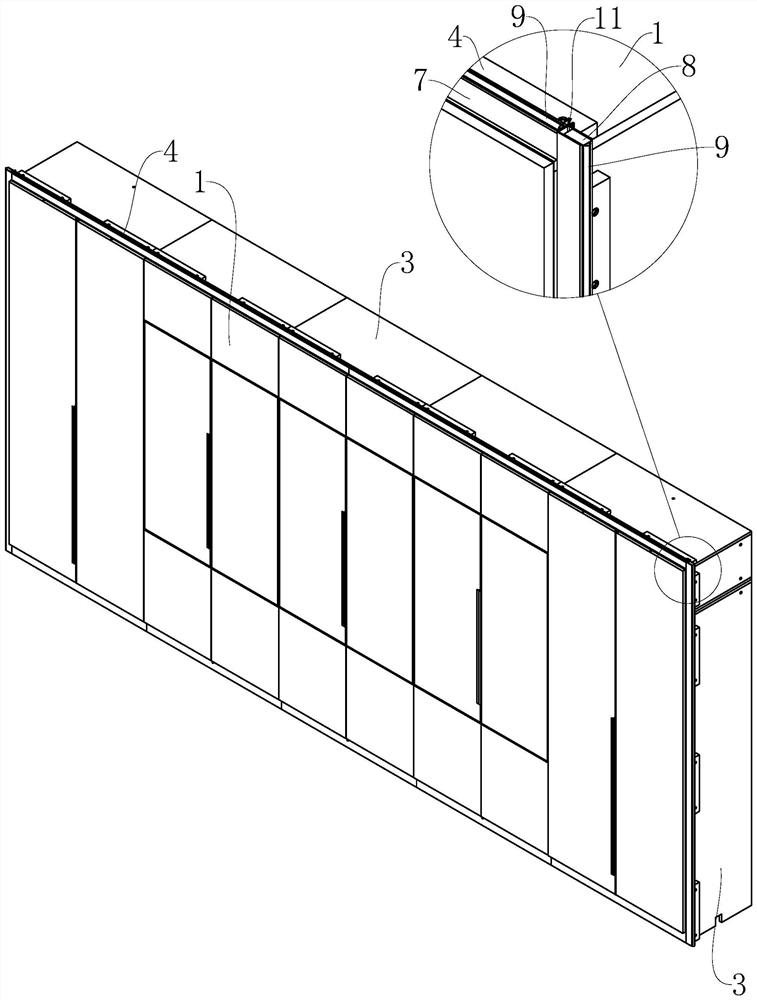

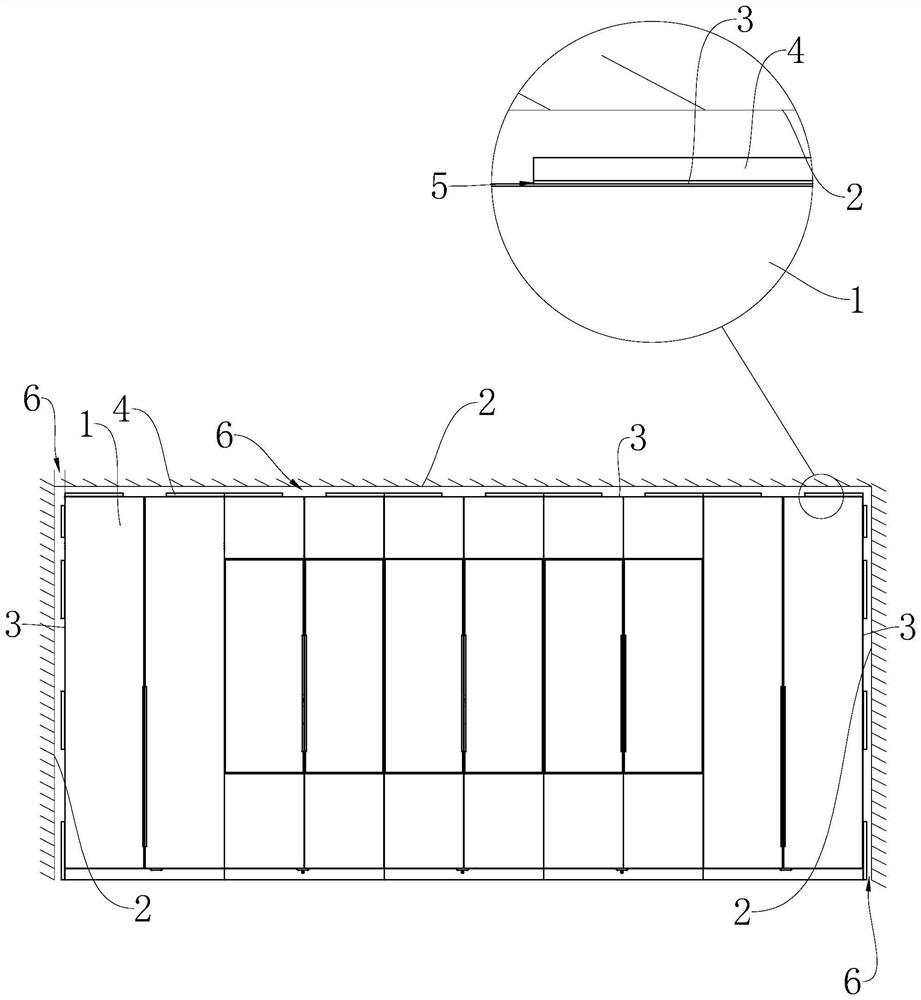

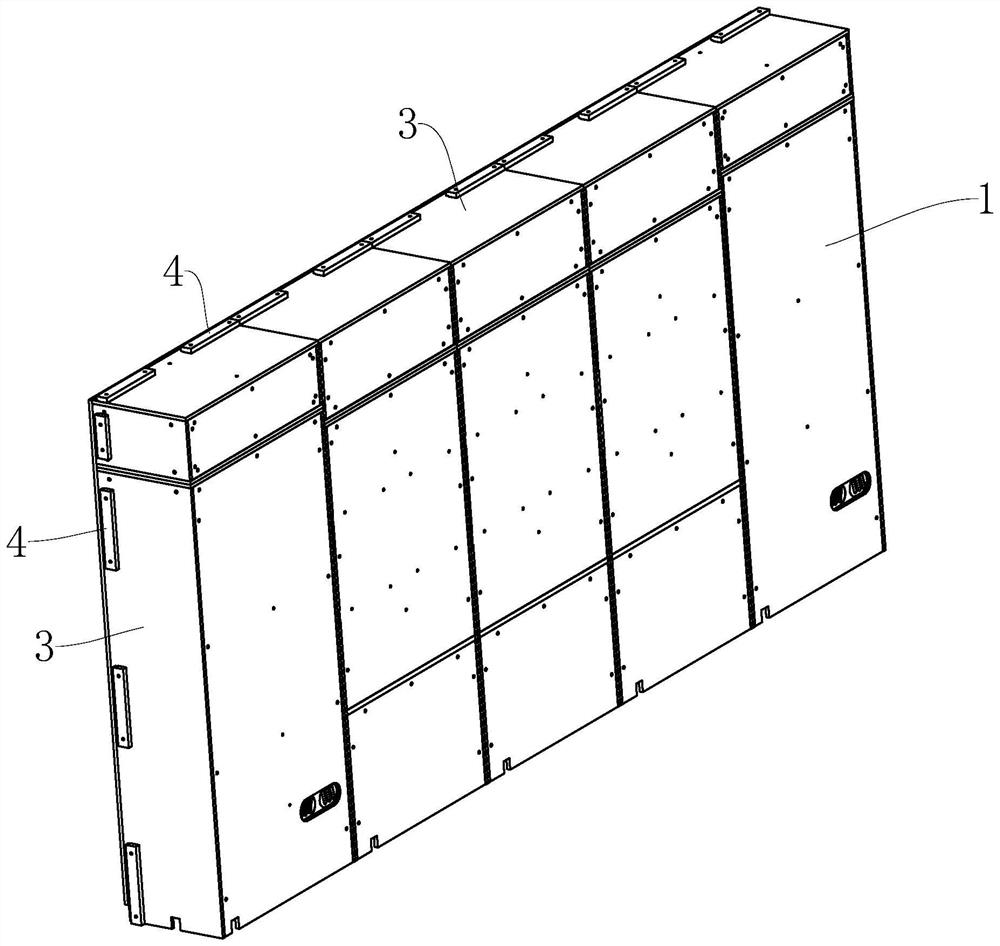

[0043] In the decoration layout, in order to make full use of the space, a space will be set up between two columns that are close to the wall or between two walls. In this space, designers often add file cabinets, Furniture such as wardrobes or bookshelves; for this type of cabinet 1 that needs to be built into the wall, it is easy to accumulate dust around it and it is difficult to clean up, because there is a narrow gap 6 between the upper surface of the cabinet 1 and the ceiling, and the same cabinet There are also such narrow gaps 6 between the two side surfaces of the body 1 and the two side walls 2, and when dust enters these gaps 6, it is difficult for the user to clean.

[0044] like Figure 10 As shown in 1-4, the present invention provides a method for fully filling the uneven gap 6 between the cabinet body 1 and the wall surface 2, comprising the following steps:

[0045] S1 determines the wall 3, and determines the wall 3 that needs to be set close to the wall or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com