Ecological grass brick for loose sandy soil in rare earth mining area and preparation and use method of ecological grass brick

A rare earth mining area and ecological technology, applied in the field of ecological grass bricks in rare earth mining areas, can solve the problems of poor sustainability, poor repair effect, loss, etc., and achieve the effect of changing physical and chemical properties and obvious soil-fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

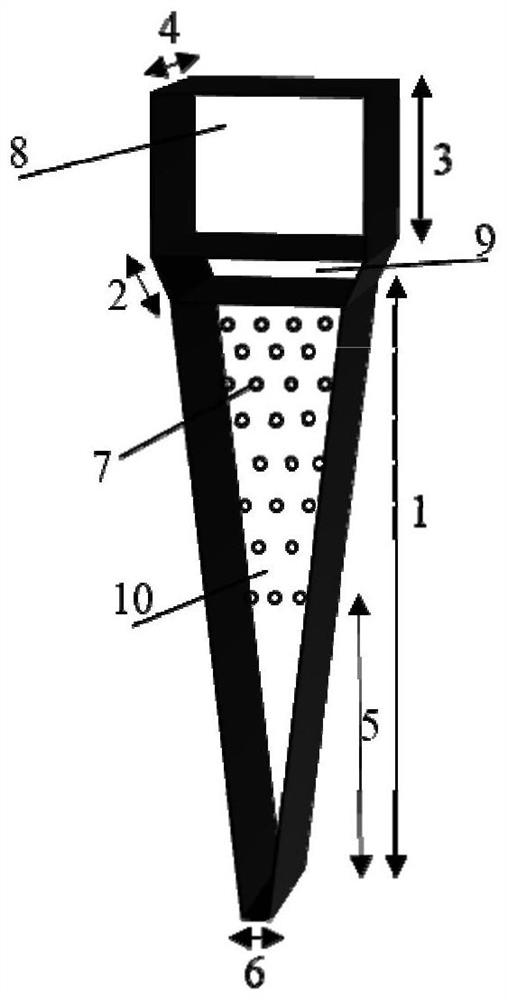

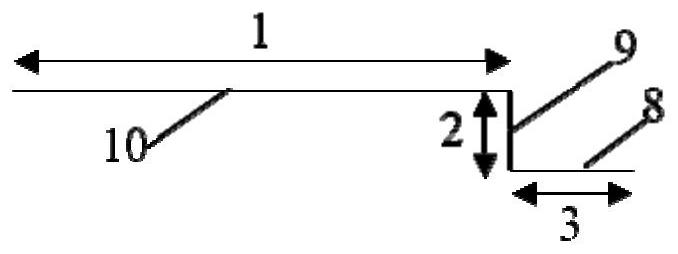

[0028] In a first aspect, a method for preparing ecological straw bricks for rare earth mining areas, comprising the following steps:

[0029] The corncob is pulverized to a particle size of less than 2cm, controlled at a relatively low temperature of 150-180°C, and anaerobic pyrolysis is performed to form corncob biomass carbon;

[0030] Pulverize the pine bark to a particle size of less than 5cm; the pine bark pulverized product: corncob biomass charcoal: the bark fiber is fully mixed according to the mass ratio of 5:3:2 to obtain the mixed material A, and the mixed material A is mixed at a humidity greater than 5:3:2. 70% of the environment, or spray water every 4-6 hours to moisturize and store for 2-3 days to soften;

[0031] Mix attapulgite: lime: water-retaining agent (sodium polyacrylate): binder (bean essence glue, skin and bone glue) in a mass ratio of 35-40:20-25:10-15:30-35, and mix it with The water is fully stirred to form a viscous liquid, and then mixed into t...

Embodiment 1

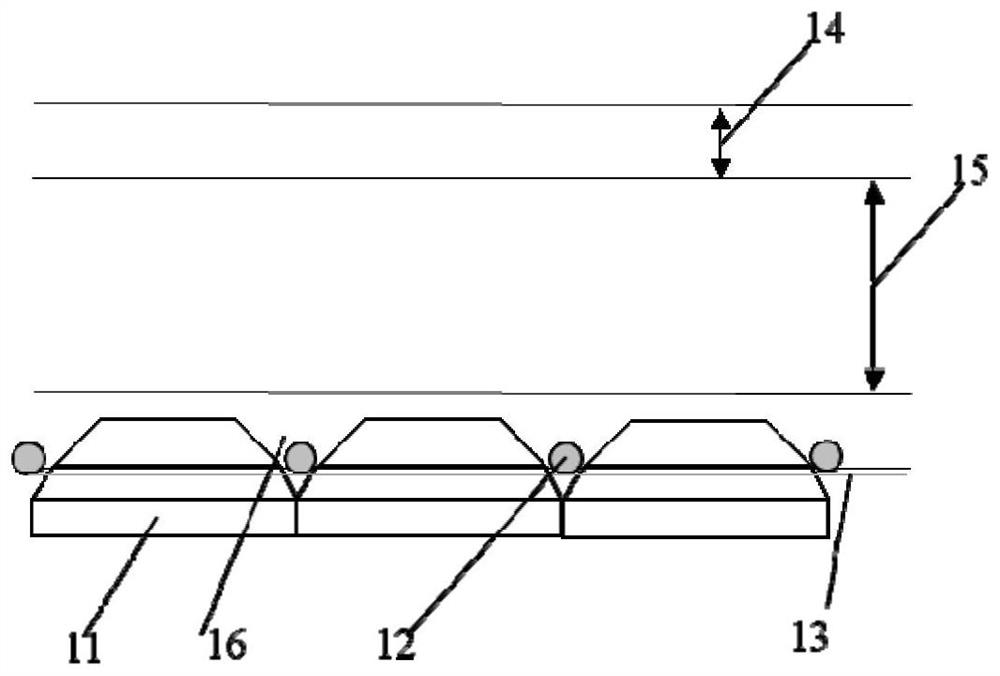

[0045] Example 1: On a loose side slope with a slope length of 5 meters in a rare earth mining area, the distance between the slope lengths is 1.5 meters, and 4 transverse grooves are opened, the groove depth is 50cm, and the width is 8cm. , the height of the stack is 5cm, the length of the top side is 5cm, the length of the bottom side is 25cm, the length of the upper side (the length of the long side of the outer stack) is 30cm, the length of the bamboo pole for fixing is 60cm, the ecological straw brick is laid with iron wire, and the soil for filling the ditch is original sandy soil, alkaline After the stone waste crushed material and the organic planting soil are fully mixed and landfilled according to the mass ratio of 4:2:4, after watering to allow the ecological grass bricks to fully absorb water, wait for 5 days and then cover the soil with the mixed soil and water, and repeat this for 3 times. The cuttings of jasmine, the spacing of the jasmine flowers is 25cm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com