Synthesis method of nano-material with surface rich in phosphate groups and fixed with Ti < 4 + > carbon spheres and application of nano-material in phosphorylated proteomics

A technology of nanomaterials and synthesis methods, applied in the field of high-throughput MALDI-TOFMS analysis, can solve the problems of complicated synthesis steps, harmful organic reagents, time-consuming and labor-intensive, etc., to achieve the best performance, optimize the reaction time, and improve the enrichment ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

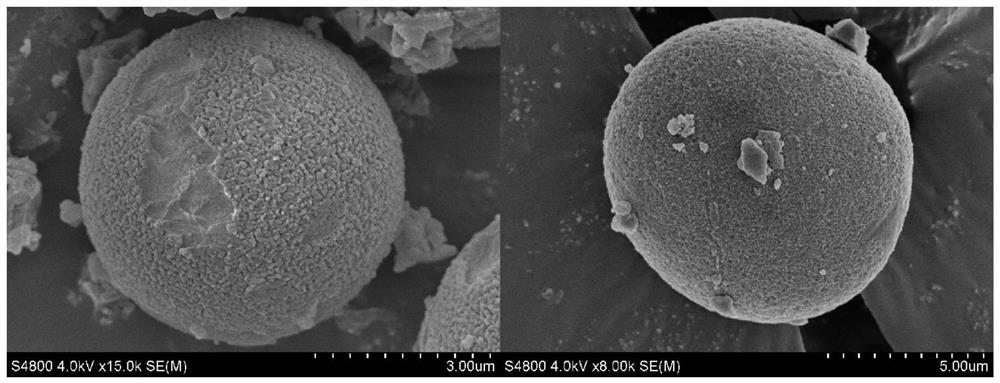

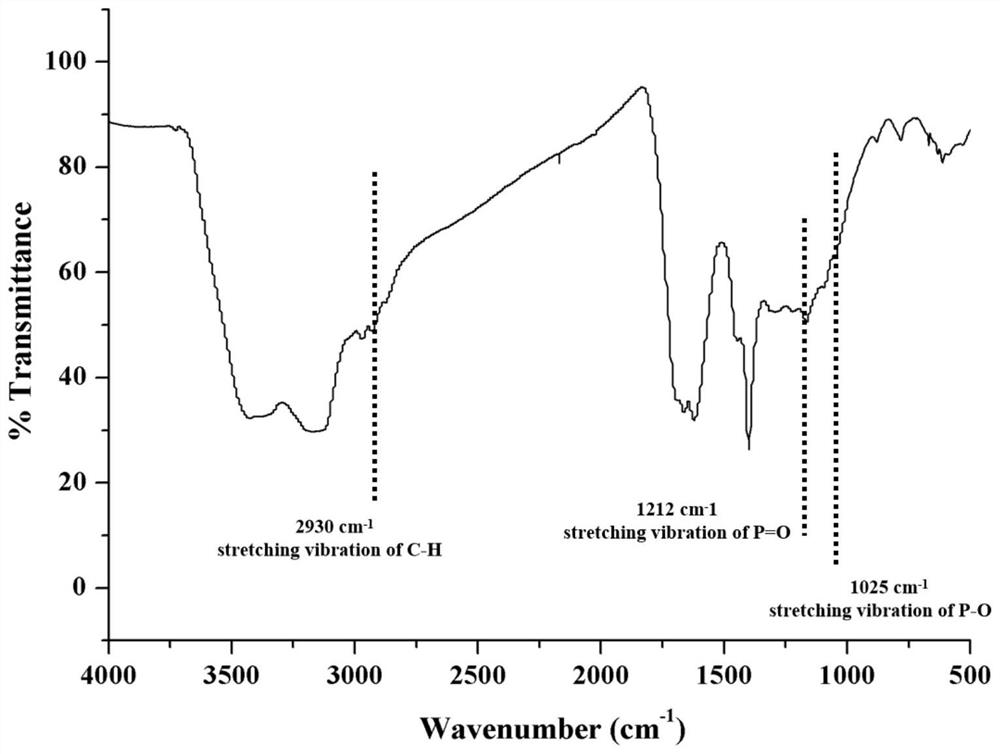

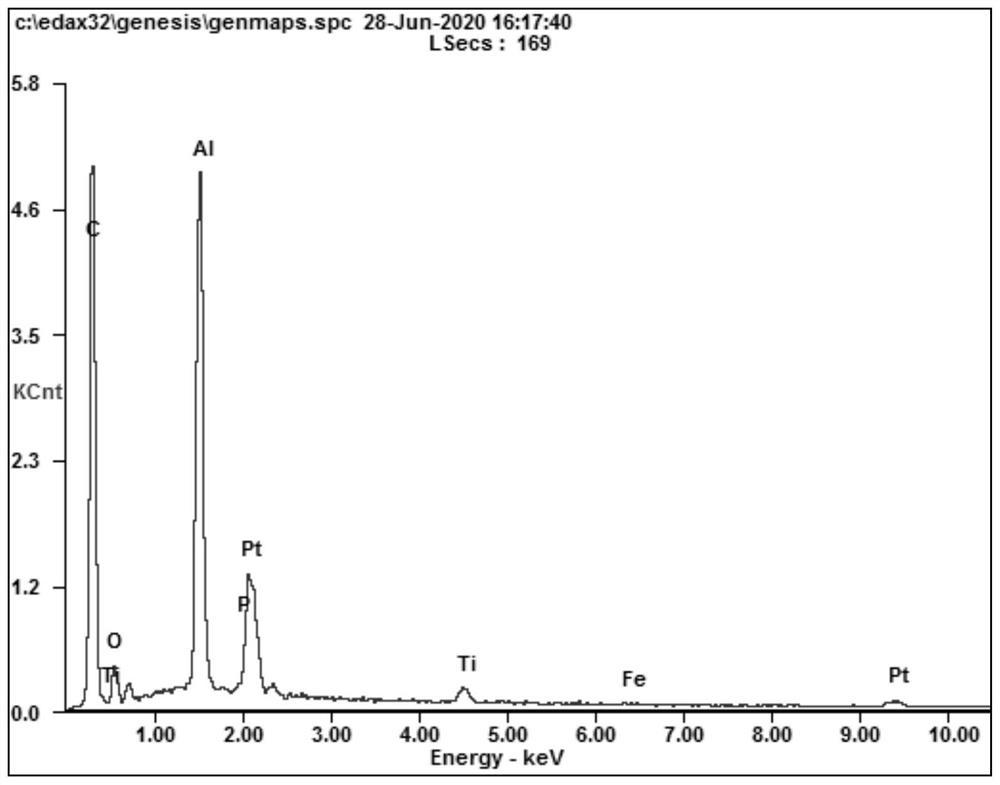

[0035] Carbon spheres rich in phosphate groups on the surface and immobilized Ti 4+ synthesis of nanomaterials;

[0036] (1) 3.04g of glucose-6-phosphate disodium (G6PNa 2 ) dissolved in 10 mL of deionized water and configured into a solution with a concentration of 1 mol / L;

[0037] (2) taking out the stainless steel reaction kettle of the polytetrafluoroethylene lining with a capacity of 25mL, and pouring the solution obtained in step (1) into it;

[0038] (3) put the reactor of step (2) into oven and react 6 hours at 180 DEG C;

[0039] (4) fully wash the product obtained in step (3) with deionized water and ethanol, remove impurities and raw material monomers on the surface of the product, and place it in a vacuum drying oven at 50 ° C to dry overnight to obtain carbon rich in phosphoric acid groups on the surface. ball material;

[0040] (5) Disperse the product obtained in step (4) into 10 mL, 100 mmol / L of Ti(SO 4 ) 2 In the solution, shake at a constant temperatu...

Embodiment 2

[0044] Application of carbon spheres rich in phosphate groups on the surface and immobilized Ti ions for phosphorylated peptides enriched in β-casein:

[0045] (1) Preparation of sample: β-casein (β-casein) in 25mmol / L NH 4 HCO 3 The solution was enzymatically hydrolyzed at 37°C for 16h.

[0046](2) Enrichment: 0.5 mg of nanomaterials were dispersed into 200 μL of 0.1% by volume TFA 50% by volume ACN centrifuge tube, then 2 μL of the sample prepared in step (1) was added, and enriched at 37°C for 30 min; Wash with a buffer ratio of TFA and 50% ACN by volume and centrifuge for 3 times; elute with 10 μL of 0.4M ammonia water for 10 min, and centrifuge to obtain the supernatant.

[0047] (3) Mass spectrometry analysis: take 0.5 μL of the supernatant target obtained in step (2), and conduct mass spectrometry analysis. The mass spectrogram is as follows Figure 4 shown, Figure 5 It is the detection limit (1fmol) of phosphorylated peptides in β-casein enriched with carbon spher...

Embodiment 3

[0049] Application of carbon spheres enriched with phosphate groups on the surface and Ti ions immobilized nanomaterials for enrichment of phosphorylated peptides in mixed proteins.

[0050] (1) Preparation of sample: bovine serum albumin (BSA) was firstly reductively alkylated with dithiothreitol and iodoacetamide, and then enzymatically hydrolyzed at 37°C for 16h. β-casein in 25mM NH 4 HCO 3 The solution was enzymatically hydrolyzed at 37°C for 16h. Bovine serum albumin (BSA) and β-casein were added in a 1000:1 molar ratio to a 50% ACN centrifuge tube containing 0.1% TFA.

[0051] (2) Enrichment: 0.5 mg of the nanomaterial obtained in Example 1 was dispersed into 200 μL of 0.1% by volume TFA 50% by volume ACN centrifuge tube containing the phosphorylated peptide of step (1), and enriched at 37°C for 30 min; The buffer solution of % TFA and 50% ACN by volume was washed and centrifuged 3 times; 10 μL of 0.4M ammonia water was washed for 15 min.

[0052] (3) Mass spectromet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com