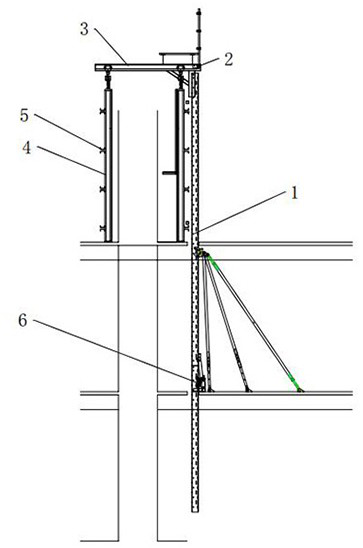

Wood formwork lower opening protection structure of hydraulic plate-penetrating creeping formwork and construction method of wood formwork lower opening protection structure

A protective structure and wood formwork technology, which is applied in the direction of formwork/formwork components, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve problems such as hidden quality problems and easy-to-appear structures. It achieves the effects of convenient construction, enhanced strength, and guaranteed quality of the lower mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

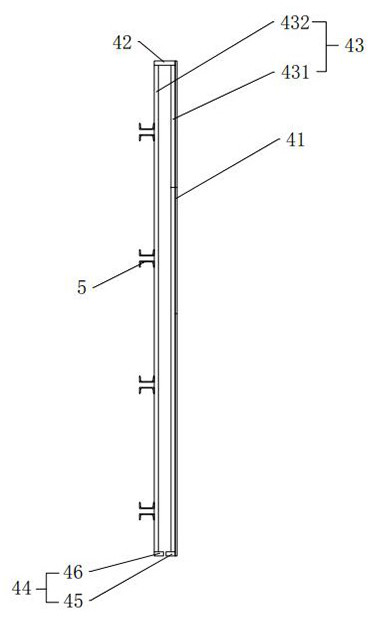

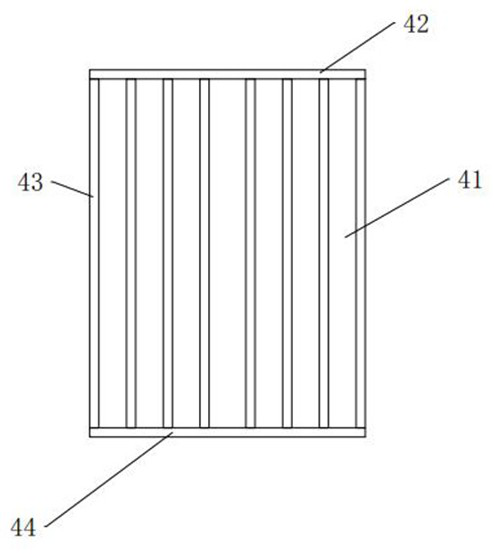

[0047] The first square steel 45 and the first row of wooden longitudinal corrugations 431 are fixed by self-tapping screws, the second square steel 46 and the second row of wooden longitudinal corrugations 432 are fixed by self-tapping screws, and the first square steel 45 and the second square steel are fixed by self-tapping screws. 46 can be fixed with self-tapping screws, which is convenient for construction.

Embodiment 2

[0049] combine Figure 4 The first square steel 45 and the second square steel 46 are respectively welded with a first angle steel 47, and the first angle steel 47 is respectively fixed on the first row of wooden square backs and the second row of wooden backs by wood screws.

[0050] A first angle steel 47 is arranged on the square steel 44, and then fixed on the first row of wooden square back corrugations and the second row of wooden square back corrugations through the first angle steel 47 and wood screws, and special wood screws for wooden square connection can be used to connect Tight, connection can be guaranteed.

Embodiment 3

[0052] like image 3 and Figure 4 , the first square steel 45 and the second square steel 46 are arranged along the width direction of the rectangular formwork.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com