Multi-component glyoxal resin adhesive as well as preparation method and application thereof

A glyoxal resin, multi-component technology, applied in the field of materials, can solve the problems of low functionality, hidden danger of formaldehyde release in particleboard, sticking to hot pressing board, etc., to eliminate unpleasant odor, excellent internal bonding strength, pleasant usability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the multi-component glyoxal resin adhesive according to the present invention includes the preparation of glyoxal urea initial polymer GU, the preparation of glyoxal-urea-melamine initial polymer GUM, the preparation of multi-component glyoxal resin preparation, including:

[0035] A. Preparation of glyoxal urea initial stage polymer GU: add glyoxal in the formula proportion to the reaction kettle, add catalyst and urea in the formula proportion under stirring, react at a temperature of 50 ~ 100 ℃ for 10 ~ 60min to obtain ethylene glycol Dialdehyde urea initial polymer GU;

[0036] B. Preparation of glyoxal-urea-melamine initial polymer GUM: adjust the pH value of glyoxal-urea initial polymer GU to 4.0~7.5, add the melamine of the formula under stirring conditions, and react at a temperature of 40~90 ° C Obtain glyoxal-urea-melamine initial polymer GUM in 10~60min;

[0037]C. Preparation of multi-component glyoxal resin: adding the aliphatic ...

Embodiment 1

[0044] (1) in the reactor, add the glyoxal of metering, add catalyzer and urea under stirring, control the mol ratio of glyoxal and urea to be 1: 0.3~0.9, control temperature at 50 ℃, insulation reaction 10 minutes, obtains ethylene glycol. Dialdehyde urea initial polymer GU;

[0045] (2) Adjust the pH value between 4.0-7.5, add metered melamine to the reaction system under stirring, control the molar ratio of glyoxal to melamine to be 1: 0.1~0.7, control the temperature at 40 ° C, and keep the reaction for 60 minutes. Obtain glyoxal-urea-melamine initial polymer GUM;

[0046] (3) adding metered fatty amine compound to the reaction system under stirring, controlling the mol ratio of glyoxal and fatty amine to be 1: 0~0.5, after 20 minutes of insulation reaction, adjust the pH value to obtain multi-component glyoxal resin ;

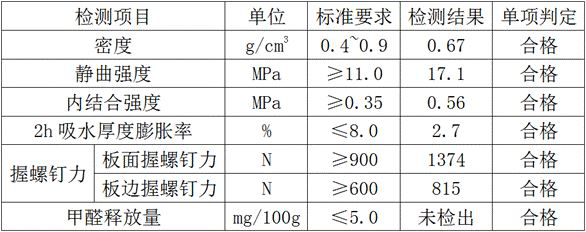

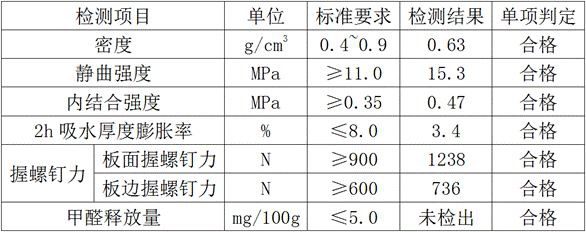

[0047] (4) After mixing the multi-component glyoxal resin, shavings and Maillard reaction reagent according to the absolute dry weight ratio of 1:5~10:0...

Embodiment 2

[0051] (1) in reactor, add the glyoxal of metering, add catalyst and urea under stirring, control the mol ratio of glyoxal and urea to be 1: 0.3~0.9, control temperature at 100 ℃, insulation reaction 60 minutes, obtains ethylene glycol. Dialdehyde urea initial polymer GU;

[0052] (2) Adjust the pH value between 4.0-7.5, add metered melamine to the reaction system under stirring, control the molar ratio of glyoxal and melamine to be 1: 0.1~0.7, control the temperature at 90 ° C, and keep the reaction for 10 minutes, Obtain glyoxal-urea-melamine initial polymer GUM;

[0053] (3) adding metered aliphatic amine compound to the reaction system under stirring, controlling the mol ratio of glyoxal and aliphatic amine to be 1: 0~0.5, after 60 minutes of insulation reaction, adjust pH value to obtain multi-component glyoxal resin ;

[0054] (4) After mixing the multi-component glyoxal resin, shavings and Maillard reaction reagent according to the absolute dry weight ratio of 1:5~10:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com