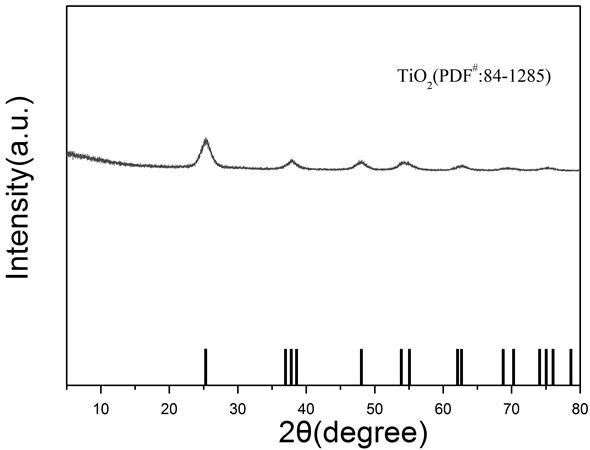

Method for preparing gas-phase nano titanium dioxide by high-temperature plasma combustion method

A nano-titanium dioxide and plasma technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of undisclosed details, improve the morphology and dispersibility, reduce the reaction temperature and production energy consumption , the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing gas-phase nano-titania by a high-temperature plasma combustion method, the steps are as follows:

[0027] 1) The raw material nano-metatitanate powder is subjected to jet pulverization and depolymerization by jet mill. Air is used as the carrier gas in the jet mill. The powder after jet pulverization and depolymerization directly enters the reaction chamber of the high temperature plasma reactor with the air. The carrier gas flow of air was 800 seem.

[0028] 2) Using air as the carrier gas, the nano-metatitanate powder is transported to the reaction chamber of the high-temperature plasma reactor. The plasma excitation gas of the high-temperature plasma reactor is nitrogen, and the nano-metatitanate powder is in the high-temperature plasma. The reaction chamber of the reactor reacts rapidly and falls to the powder collection system of the high temperature plasma reactor. The plasma flame temperature of the high temperature plasma reactor is 1800 ...

Embodiment 2

[0034] A method for preparing gas-phase nano-titania by a high-temperature plasma combustion method, the steps are as follows:

[0035] 1) The raw material nano-metatitanate powder is subjected to jet pulverization and depolymerization by jet mill. Air is used as the carrier gas in the jet mill. The powder after jet pulverization and depolymerization directly enters the reaction chamber of the high temperature plasma reactor with the air. The carrier gas flow of air was 700 seem.

[0036] 2) Using air as the carrier gas, the nano-metatitanate powder is transported to the reaction chamber of the high-temperature plasma reactor. The plasma excitation gas of the high-temperature plasma reactor is nitrogen, and the nano-metatitanate powder is in the high-temperature plasma. The reaction chamber of the reactor reacts rapidly and falls to the powder collection system of the high temperature plasma reactor. The plasma flame temperature of the high temperature plasma reactor is 2000 ...

Embodiment 3

[0039] A method for preparing gas-phase nano-titania by a high-temperature plasma combustion method, the steps are as follows:

[0040] 1) The raw material nano-metatitanate powder is subjected to jet pulverization and depolymerization by jet mill. Air is used as the carrier gas in the jet mill. The powder after jet pulverization and depolymerization directly enters the reaction chamber of the high temperature plasma reactor with the air. The carrier gas flow of air was 650 seem.

[0041]2) Using air as the carrier gas, the nano-metatitanic acid powder is transported to the reaction chamber of the high-temperature plasma reactor. The plasma excitation gas of the high-temperature plasma reactor is argon, and the nano-metatitanic acid powder is in the high temperature plasma. It reacts rapidly in the reaction chamber of the plasma reactor and falls to the powder collection system of the high temperature plasma reactor. The plasma flame temperature of the high temperature plasma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com