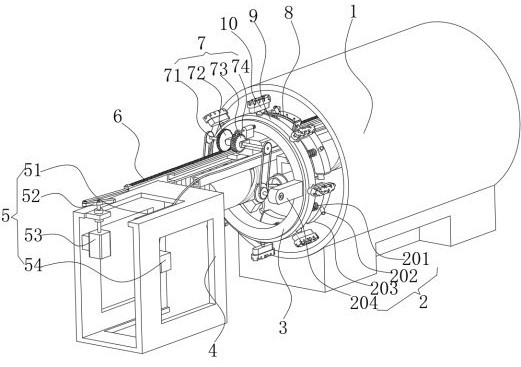

Arc surface polishing equipment for interior of carbonization furnace body

An arc surface, carbonization furnace technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve problems such as incomplete furnace cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

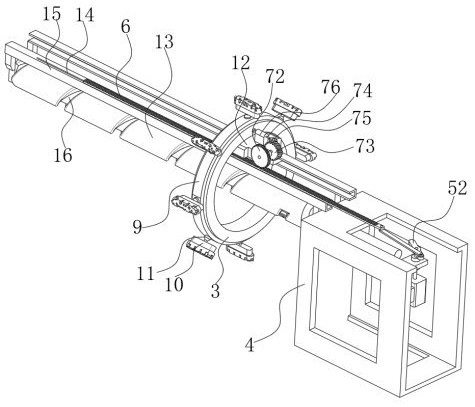

Method used

Image

Examples

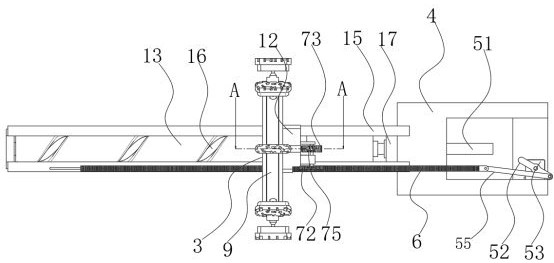

Embodiment 2

[0048] refer to Figure 10 and 12 , an arc surface grinding device for the interior of the carbonization furnace body. Compared with Embodiment 1, this embodiment also includes an arc-shaped nozzle 8 fixed to the vertical side of the buffer air pipe 203 near the top end, and The arc-shaped nozzle 8 is located on the side of the buffer air pipe 203 close to the annular rail 3 , a softener pump 54 is arranged inside the main box 4 , and the output end of the softener pump 54 and the end of the arc-shaped nozzle 8 are arranged There is a conveying hose 801; the top of the arc-shaped nozzle 8 is provided with a vertical upward nozzle; when in use, when the propulsion mechanism drives the whole forward, the arc-shaped nozzle 8 can be sprayed in advance to soften the position to be polished It makes the later grinding work easier and reduces the frequency of hard lumps.

[0049] Wherein, the inner wall of the main box 4 is provided with a hose reel 802 near the top, and the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com