Ultra-large aluminum alloy vacuum die-casting system and method

A technology of vacuum die casting and aluminum alloy, applied in the field of super large aluminum alloy vacuum die casting system, can solve the problems such as the inability to effectively guarantee the quality of die castings, the residue of mold cavity gas or flue gas, and the residual mold cavity gas or flue gas. , to achieve the effect of improving die-casting efficiency and production beat, ensuring quality and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

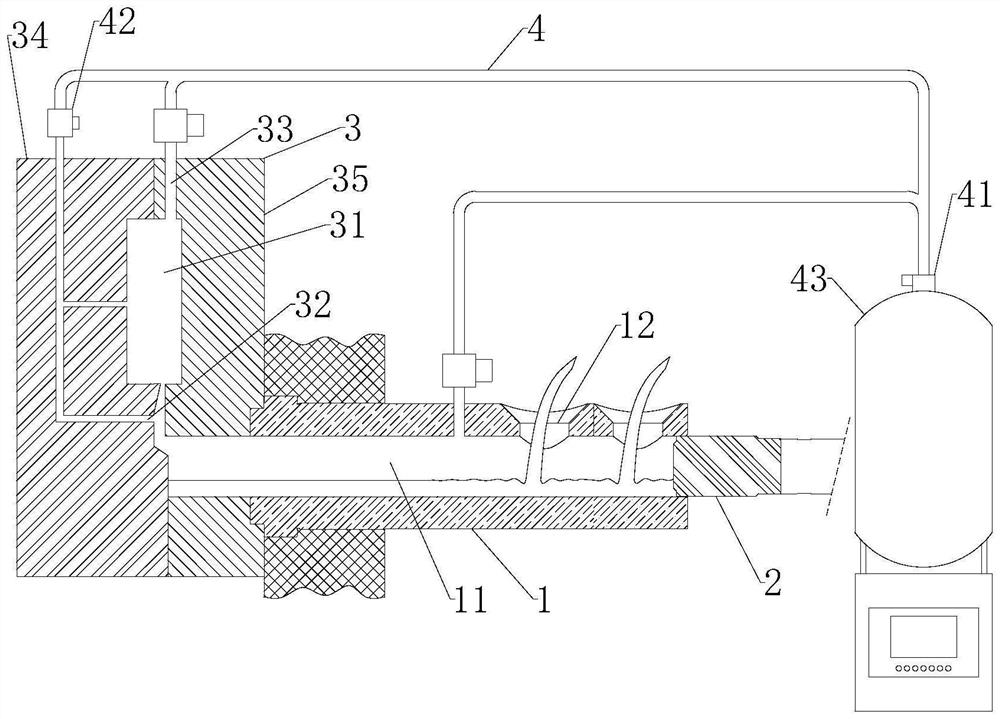

[0035] like Figure 1-4 As shown, an ultra-large aluminum alloy vacuum die casting system includes a pressure chamber body 1 with a pressure chamber 11 inside, a punch 2 arranged in the pressure chamber 11, a mold mechanism 3 with a mold cavity 31 inside, and a vacuum generator. Mechanism 4 and controller, the pressure chamber body 1 includes at least one material pouring port 12 communicated with the pressure chamber 11, the pressure chamber 11 is connected with the mold cavity 31, and the end of the mold cavity 31 close to the pressure chamber 11 is connected with a At least one first air extraction channel 32, one end of the cavity 31 away from the pressure chamber 11 is connected with a second air extraction channel 33, the first air extraction channel 32 and the second air extraction channel 33 are both connected to the vacuum generating mechanism 4. connected, the punch 2 and the vacuum generating mechanism 4 are both connected to the controller.

[0036] Specifically, ...

Embodiment 2

[0039] like Figure 1-4 As shown, in this embodiment, the pressure chamber body 1 includes at least two material feeding ports 12, and the feeding feeding ports 12 are distributed at equal intervals along the injection direction. Specifically, when pouring aluminum liquid, the aluminum liquid can be poured into the pressure chamber 11 through the two pouring ports 12 at the same time, so as to increase the contact area of the aluminum liquid with the outside world during the pouring process, and dissipate the heat of the aluminum liquid to a certain extent. , reduce the erosion of the pressure chamber 11 when the aluminum liquid is poured through the pressure chamber 11; when the capacity of the pressure chamber 11 is constant, the aluminum liquid is poured through a plurality of pouring ports 12 to reduce the time for the aluminum liquid to erode the same area, Improve the service life of the pressure chamber body 1 . Further, the pouring port 12 can be used intermittently...

Embodiment 3

[0041] like Figure 1-4 As shown, in this embodiment, the discharge port 12 includes a flared portion 121 and a vertical portion 122, the flared portion 121 is connected to the pressure chamber 11 through the vertical portion 122, and the side of the vertical portion 122 is vertical On the horizontal plane, the sides of the flared portion 121 are inclined outward from the vertical portion 122 , and the side of the flared portion 121 close to the vertical portion 122 forms a first end surface, and the side of the flared portion 121 The end of the side away from the vertical portion 122 forms a second end face, the first end face is larger than the second end face, and the second end face coincides with the projection of the side of the vertical portion 122 on the horizontal plane. That is to say, the discharge port 12 adopts the design of "sloping up and straight down", the flared part 121 is a funnel-shaped opening, and the vertical part 122 is a straight opening. The flared p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com