Automatic cleaning system for soil electrokinetic remediation electrode and use method of automatic cleaning system

An electric remediation and automatic cleaning technology, applied in the field of soil remediation, can solve problems such as the inability to effectively reduce soil acidity, alkalization, reduction of remediation efficiency, and obstruction of material flow, so as to improve remediation efficiency, reduce energy consumption, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, not to limit the present invention, and in no way limit the protection scope of the present invention.

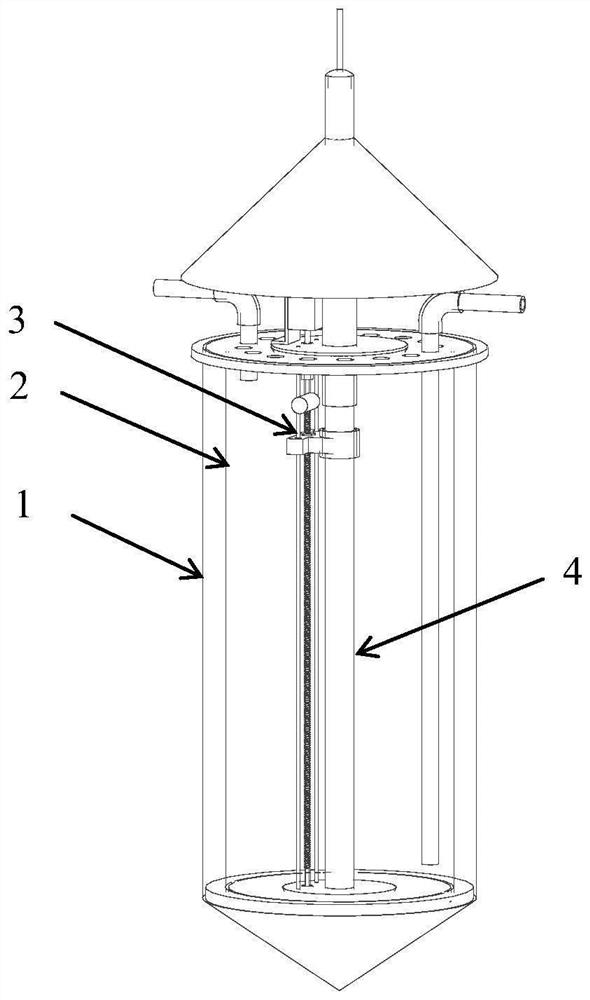

[0053] A soil electric remediation electrode automatic cleaning system and its use method, see attached figure 1 , including the outer shield 1, the inner screen cover 2, the cleaning module 3 and the electrode body 4, the inner screen cover 2 is arranged in the outer shield 1, the electrode body 4 is vertically inserted in the inner screen cover 2, and the cleaning module 3 It is arranged in the inner mesh cover 2 to clean the electrode body 4 . The structure of this electrode system will be specifically described below.

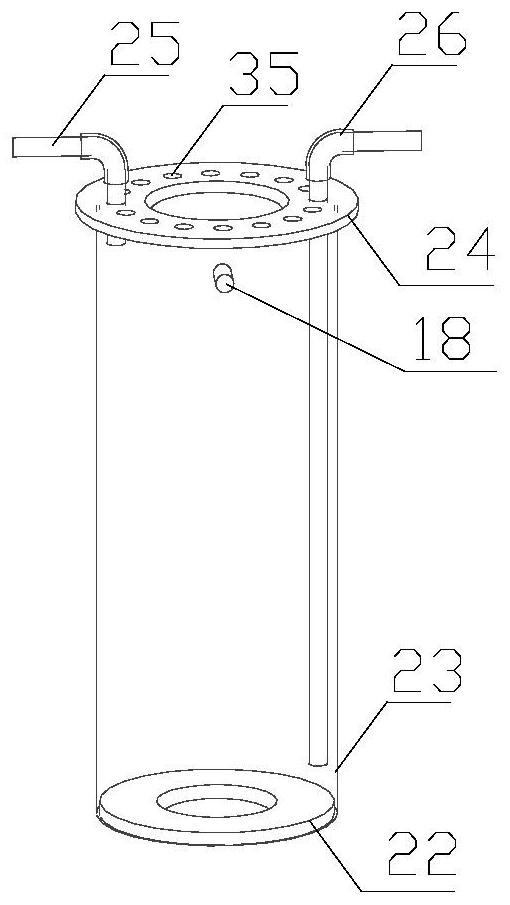

[0054] see attached figure 2 , the outer shield 1 includes a conical cover 19, an outer mesh cylinder 20, and a reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com