Planar microneedle, microneedle patch, manufacturing equipment, vertical equipment and preparation method

A technology for manufacturing equipment and microneedles, applied in the field of microneedles, can solve the problems of uncontrollable dosage, difficult demoulding, large depth of forming groove and depth-to-length ratio, etc., to avoid fracture, reduce demolding resistance, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

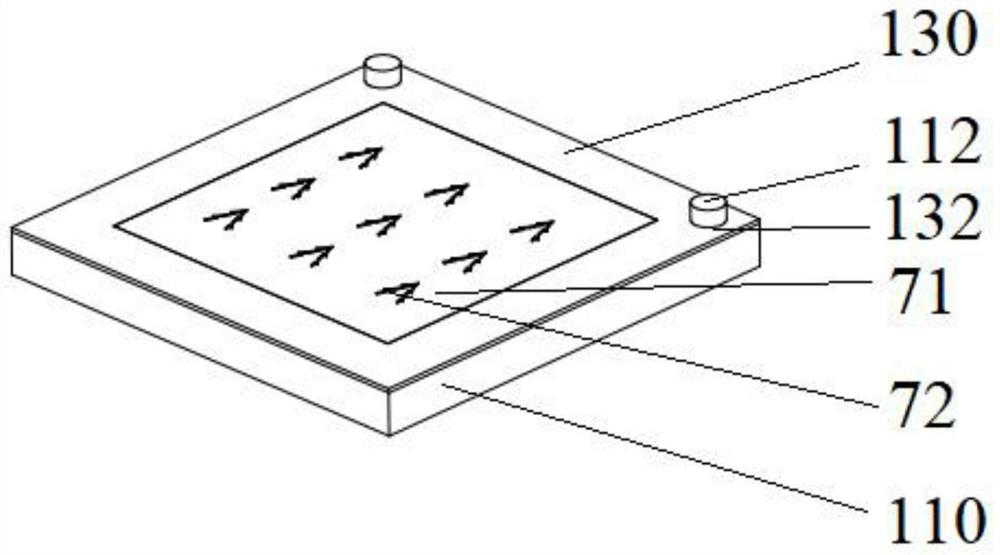

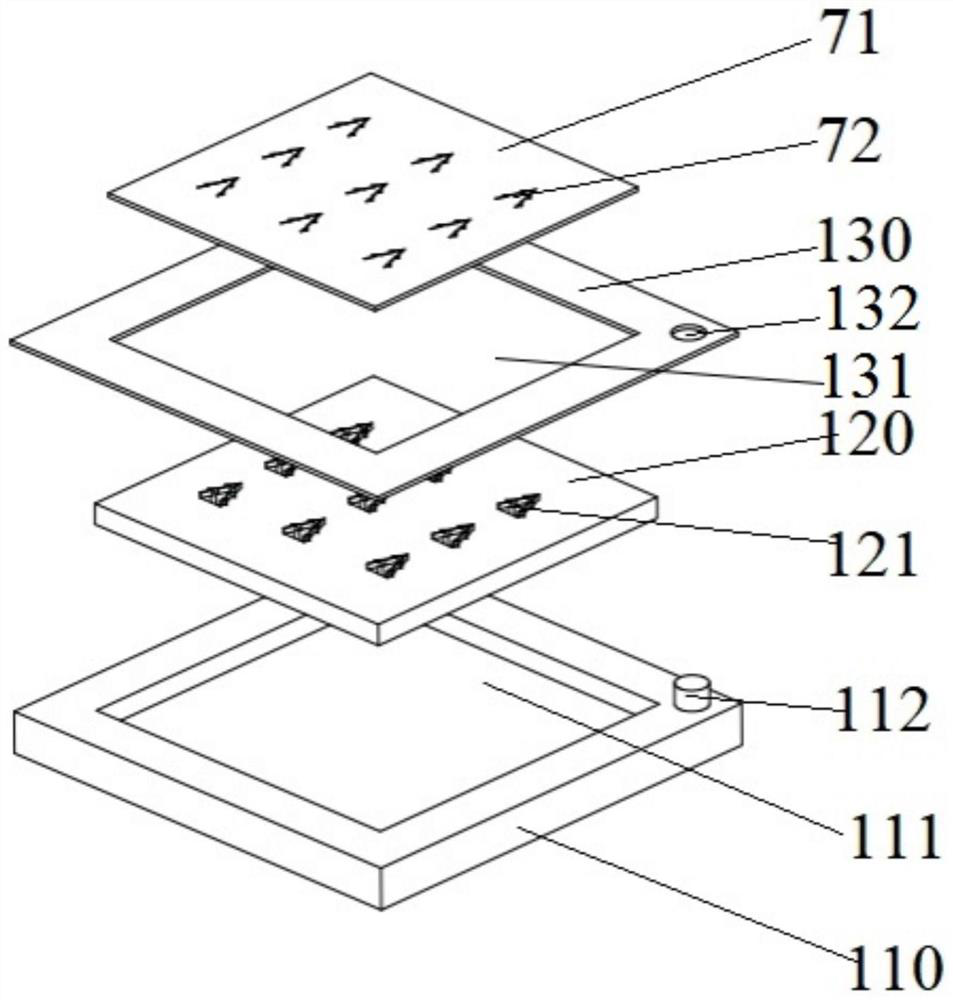

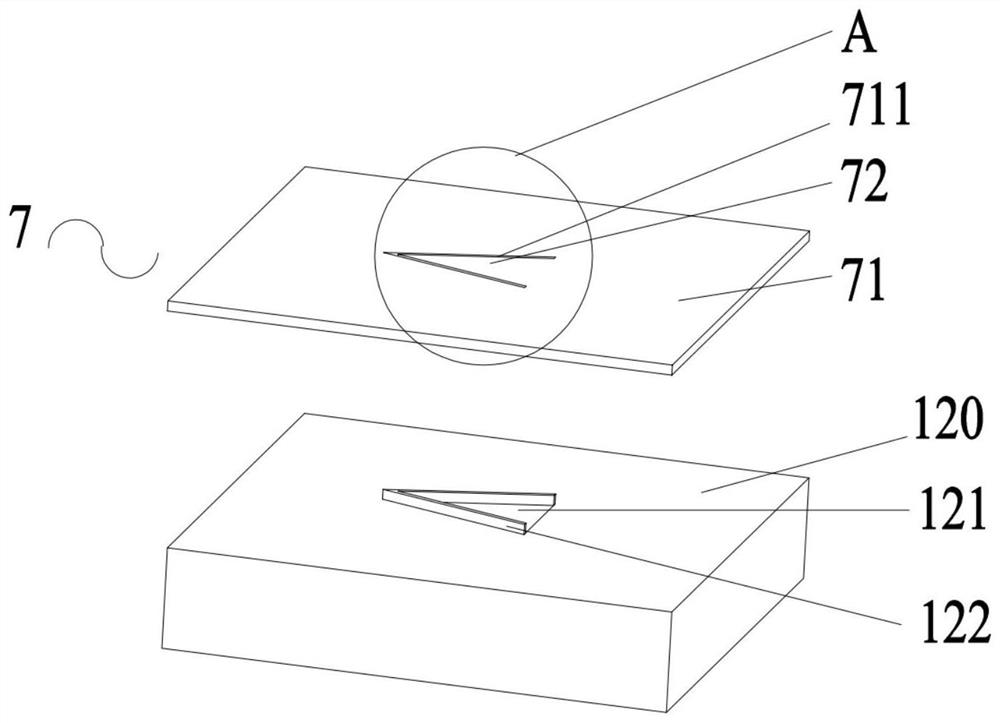

[0092] see Figure 1-32 As shown, an embodiment of the present invention provides a flat microneedle, including a base layer 71 and a microneedle 72 disposed on the base layer 71 . The microneedle 72 includes a needle tip 721 , a needle base 723 and a middle portion 722 connecting the needle tip 721 and the needle base 723 . The direction of the needle tip 721 toward the needle seat 723 is the same as the extending direction of the base layer 71 , and the microneedle 72 is formed by the forming groove 121 in the mold 120 . The direction of the needle tip groove 1211 for forming the needle tip 721 toward the needle seat groove 1213 for forming the needle seat 723 is horizontal, so as to reduce the depth of the forming groove 121 and reduce the ratio of the maximum depth to the maximum length of the forming groove 121 , so that the drug-carrying liquid can be accurately poured into the needle tip groove 1211 of the forming groove 121 . Since the forming groove 121 of the micro...

Embodiment 2

[0105] On the basis of Embodiment 1, this embodiment provides a microneedle patch 8 .

[0106] see Figure 1-32 , the microneedle patch 8 includes an adhesive layer 6 . The working principle of changing from the plane microneedle 7 to the microneedle sticker 8 is as follows: the adhesive layer 6 is adhered to the base layer 71 close to the side of the microneedle 72 protruding from the base layer 71 , the connection between the first surface 724 and the second surface 725 There is a gap 711 between the surface and the base layer 71, the microneedles 72 rotate around the connection between the third surface 726 and the base layer 71 until the third surface 726 and the base layer 71 are on the same plane, the microneedles 72 are vertical, and the third surface 726 is adhered to the adhesive layer 6, and the microneedles 72, the base layer 71 and the adhesive layer 6 are arranged in order from top to bottom and combined into the microneedle sticker 8. At this time, the direction...

Embodiment 3

[0110] see Figure 1-23 As shown, on the basis of Embodiment 1 and Embodiment 2, the embodiment of the present invention provides a manufacturing apparatus for flat microneedles.

[0111] The manufacturing equipment of the planar microneedle includes a base 110 , a mold 120 and a panel 130 located above the base 110 . The top of the base 110 is provided with an accommodating groove 111 for accommodating the mold 120 . The top of the mold 120 is provided with a plurality of molding grooves 121 for molding the microneedles 72 . The forming groove 121 includes a needle point groove 1211 , a needle seat groove 1213 and a middle groove 1212 connecting the needle point groove 1211 and the needle seat groove 1213 . The direction of the needle point groove 1211 toward the needle seat groove 1213 is a horizontal direction. The needle tip groove 1211 is used to form the needle tip 721 of the microneedle 72, the middle groove 1212 is used to form the middle part 722 of the microneedle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com