Polarizing plate and image display device using same

A technology of polarizing plate and polarizing element, which can be used in identification devices, polarizing elements, lighting devices, etc., can solve the problem of insufficient suppression effect, and achieve the effect of small reduction in transmittance, excellent high temperature durability, and suppression of transmittance reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 》

[0048]The polarizing plate of the first embodiment of the present invention has a polarizing element obtained by adsorbing iodine to a polyvinyl alcohol-based resin layer and orienting iodine, and includes at least one selected from the group consisting of urea, urea derivatives, thiourea, and thiourea derivatives. A urea-based compound layer of a urea-based compound, and a transparent protective film. The polarizing plate of this embodiment has the characteristic of at least one of the following (a) and (b).

[0049] (a) The moisture content of the polarizing element is equal to or more than the equilibrium moisture content at a temperature of 20°C and a relative humidity of 30%, and is equal to or less than an equilibrium moisture content at a temperature of 20°C and a relative humidity of 50%.

[0050] (b) The moisture content of the polarizing plate is equal to or more than the equilibrium moisture content at a temperature of 20°C and a relative humidity of 30%, and is equ...

no. 2 Embodiment approach 》

[0141] A polarizing plate according to a second embodiment of the present invention includes a polarizing element which is formed by adsorbing iodine to a polyvinyl alcohol-based resin layer and orienting iodine, and includes a polarizing element selected from the group consisting of urea, urea derivatives, sulfur At least one urea-based compound among urea and thiourea derivatives. The polarizing plate of this embodiment has the characteristic of at least one of the following (a) and (b).

[0142] (a) The moisture content of the polarizing element is equal to or more than the equilibrium moisture content at a temperature of 20°C and a relative humidity of 30%, and is equal to or less than an equilibrium moisture content at a temperature of 20°C and a relative humidity of 50%.

[0143] (b) The moisture content of the polarizing plate is equal to or more than the equilibrium moisture content at a temperature of 20°C and a relative humidity of 30%, and is equal to or less than a...

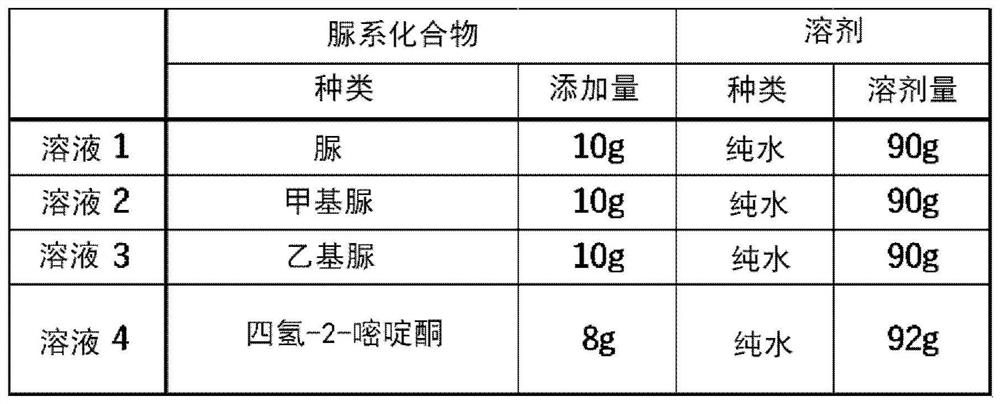

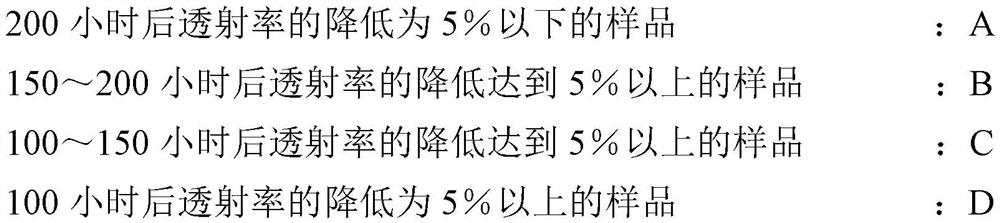

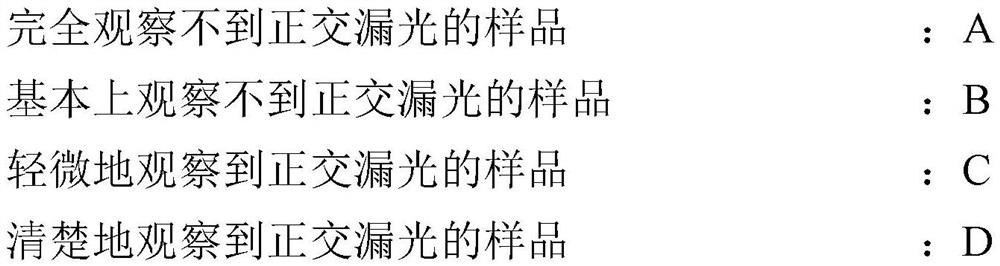

Embodiment 1~9、 comparative example 1~6

[0187] In Examples 1 to 9 and Comparative Examples 1 to 6, the optical laminates shown in Table 2 were used. Stored for 72 hours under the conditions of ℃ and relative humidity of 35%, 40%, 45%, 50% or 55%. The moisture content of the optical laminate can be considered to be in equilibrium with the moisture content of the storage environment, and the moisture content of the polarizing plate and the polarizing element in the optical laminate can also be considered to be the same as the moisture content of the optical laminate.

[0188] (Polarizing plate for inspection 1)

[0189] An acrylic pressure-sensitive adhesive (manufacturer: LINTEC Co., Ltd., model number: #7) was laminated only on one side of the polarizing plate 1, and the polarizing plate 1 for inspection was produced. The polarizing plate 1 for inspection produced in this way was cut into a size of 50 mm × 100 mm so that the short side was parallel to the absorption axis, and the surface of the pressure-sensitive a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Saponification degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com