Multi-roller synchronous control method and related device

A technology of synchronous control and pinch rollers, which is applied in the fields of equipment and computer readable storage media, multi-roller synchronous control, and multi-roller synchronous control devices. It can solve complex debugging, high machining requirements, and inability to install line speed calibration sensors, etc. problem, achieve the effect of preventing internal friction and reducing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

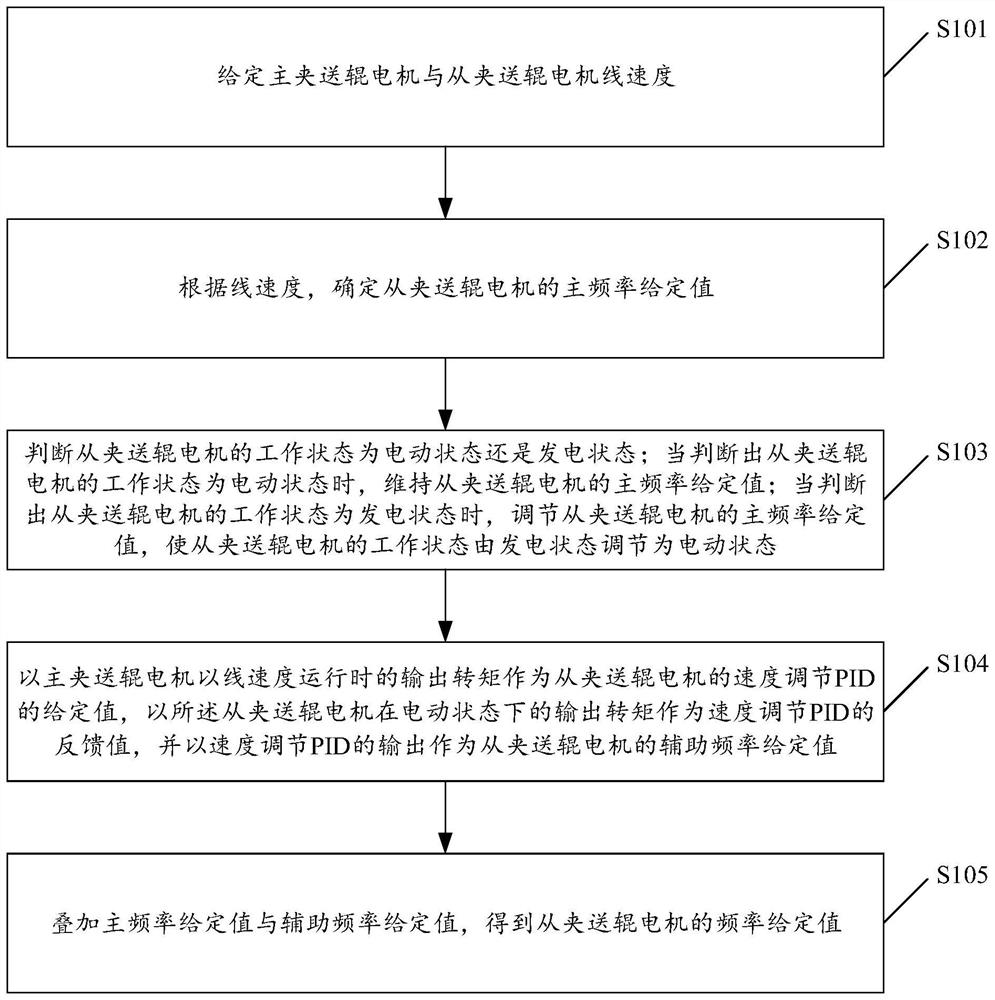

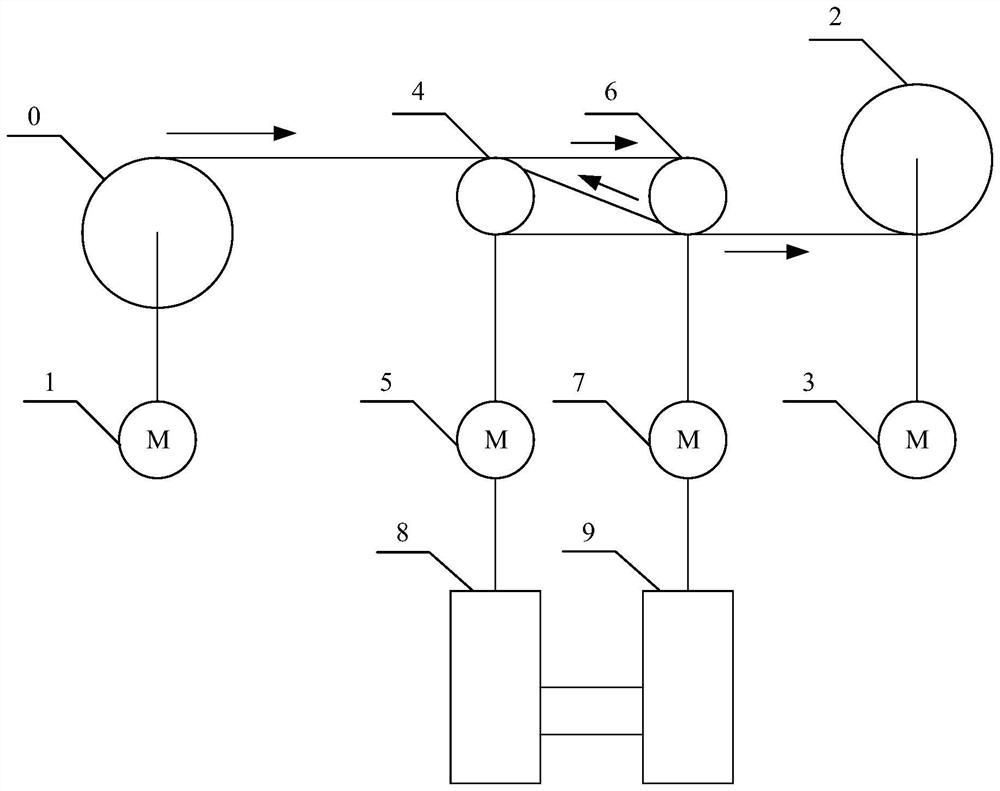

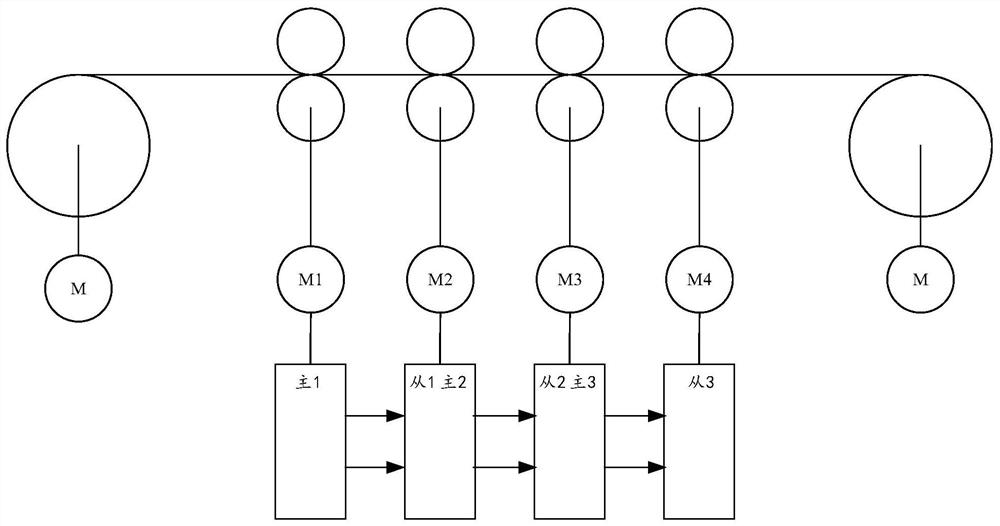

[0048] The core of the present application is to provide a multi-roller synchronous control method, which can achieve the same linear speed of the main pinch roller motor and the slave pinch roller motor without external sensors, which not only reduces the machining requirements and equipment manufacturing costs, It can also avoid the phenomenon of internal friction and reduce the energy consumption of the system. Another core of the present application is to provide a multi-roller synchronization control device, equipment and computer-readable storage medium, all of which have the above technical effects.

[0049] In order to make the purposes, technical solutions and advantages of the embodiments of the present application more clear, the technical solutions in the embodiments of the present application will be described clearly and completely below with reference to the drawings in the embodiments of the present application. Obviously, the described embodiments It is a part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com