Integrated gradient material box body packaging structure for airtight rectangular connector

A rectangular connector and gradient material technology, which is applied to the components, connections, and coupling devices of connecting devices, can solve problems such as reducing internal stress, ensure compatibility, improve packaging reliability and integration density, and ensure air tightness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

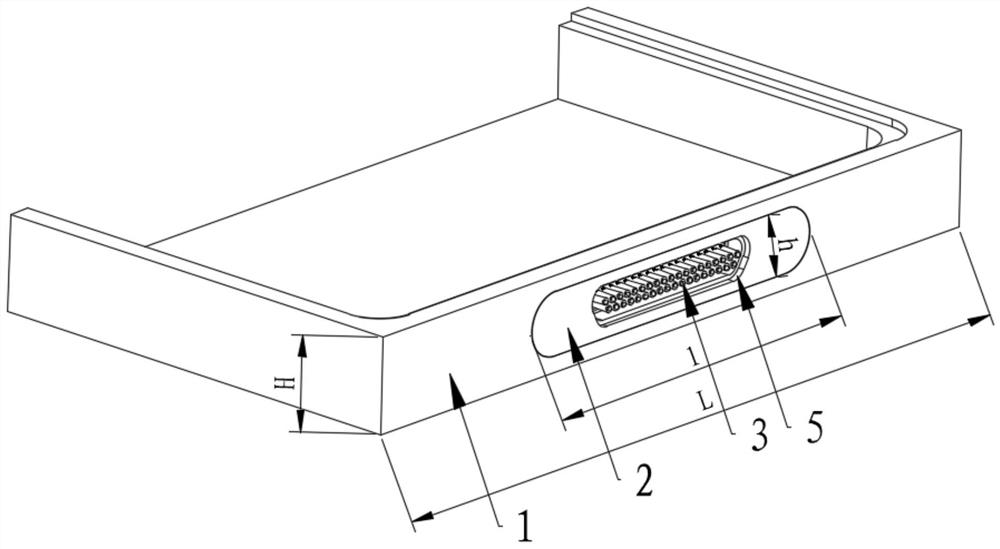

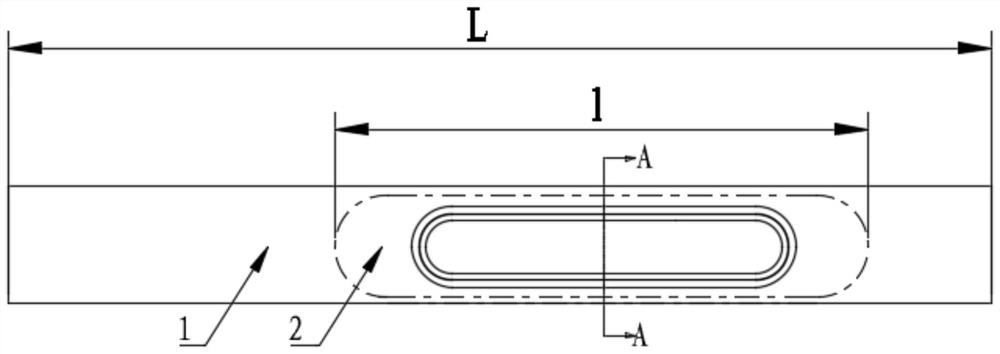

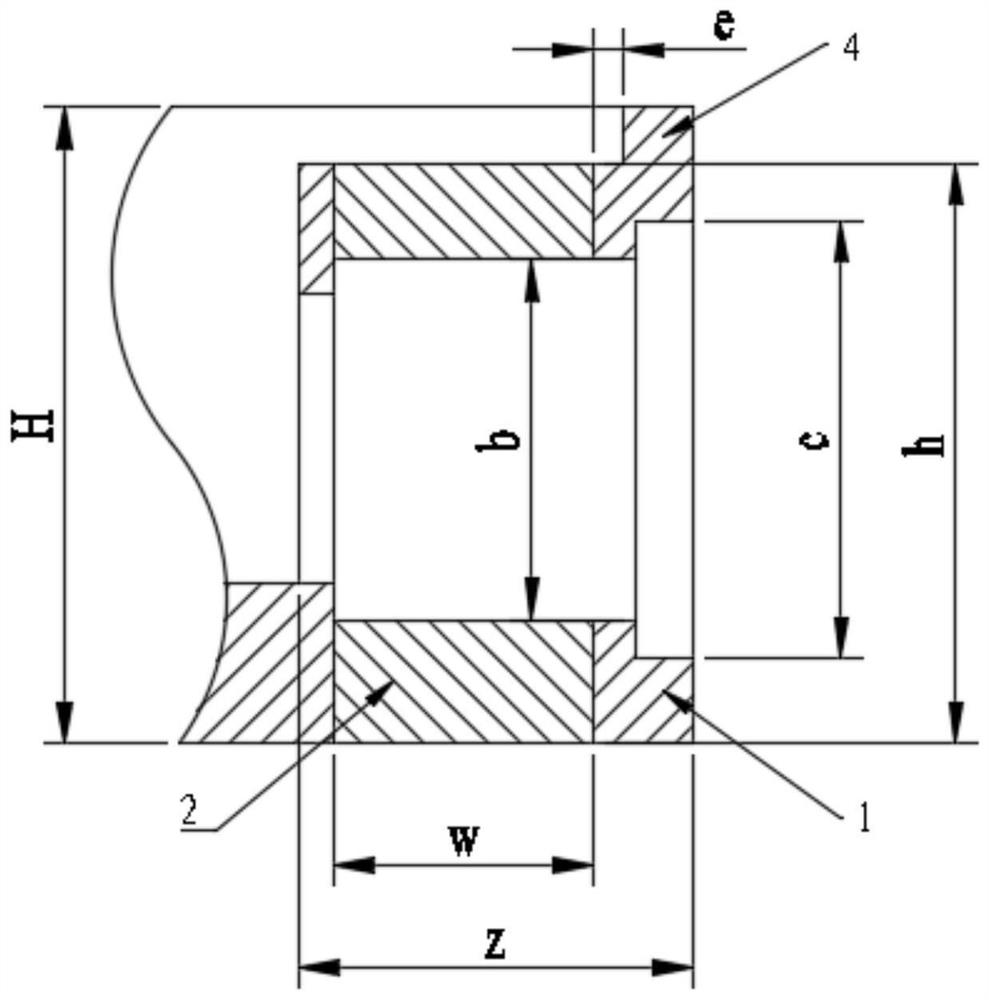

[0043] like Figure 2-Figure 3 shown:

[0044] This embodiment is mainly applicable to the connection between the chip and the rectangular connector 3 in the high-density integrated design. The high-density integrated design described here specifically refers to: H-h≤0.5mm.

[0045] An integrated gradient material box body packaging structure facing an airtight rectangular connector 3, comprising a main body 1 provided with a rectangular connector packaging area and a chip mounting area, an adjustment device located in the rectangular connector packaging area and integrally formed with the main body 1 body 2 ; the thermal expansion coefficient of the regulating body 2 is smaller than that of the main body 1 and greater than that of the rectangular connector 3 ; the regulating body 2 is provided with mounting holes for installing the airtight rectangular connector 3 .

[0046] In the present invention, the main body 1 and the regulating body 2 are prepared by powder metallurgy...

Embodiment 2

[0063] like figure 1 , Figure 4 , Figure 5 As shown in the figure, the difference between this embodiment and the above-mentioned embodiment is that the adjustment body 2 will be coplanar with the outer side of the main body 1; it is mainly suitable for the packaging of chips and rectangular connectors 3 in the case of non-high-density integrated design, described here. The non-high-density integrated design refers to H-h>0.5mm.

Embodiment 3

[0065] like figure 1 , Figure 4 , Figure 5 As shown, when packaging a chip or a rectangular connector 3 that is not designed for high-density integration;

[0066] The main body 1 and the regulating body 2 are made of two gradient materials of the main body 1 and the regulating body 2 into an integrated box body blank by powder metallurgy, and then the integrated gradient material is produced by the process route of precise numerical control machining and surface treatment. Box body packaging structure; wherein, the material of the main body 1 is 6063 aluminum alloy, and its thermal expansion coefficient is 23; the material of the regulating body 2 is AlSi composite material with a silicon content of 50%, the thermal expansion coefficient is 11, and the thermal expansion coefficient of the rectangular connector 3 shell is 5; the thermal expansion coefficient of the transition connecting section between the regulating body 2 and the main body 1 is 17;

[0067] By setting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com