Tablet missing detection method and system based on machine vision

A machine vision and detection method technology, applied in the field of visual inspection, can solve the problems of inability to accurately detect packaging errors, labor-intensive, and manual omissions, etc., to achieve the effect of improving detection accuracy and detection efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

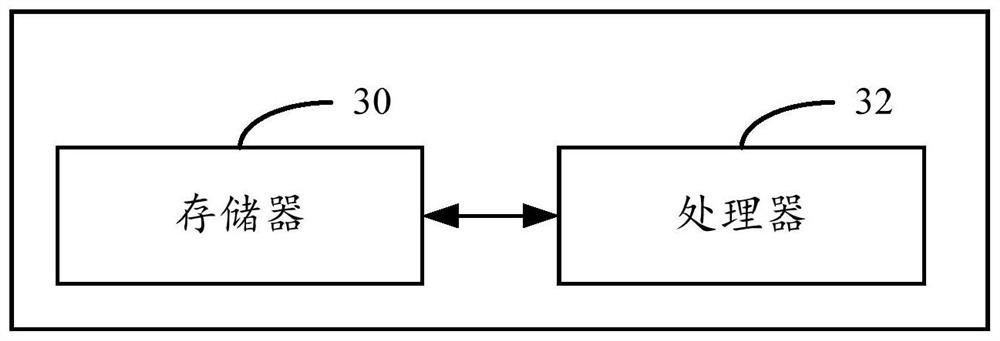

[0073] Embodiments of the present invention provide a device for detecting missing tablets based on machine vision, such as image 3 As shown, it includes: a memory 30, a processor 32 and a computer program stored on the memory 30 and running on the processor 32, the computer program being executed by the processor 32 to implement the following method steps:

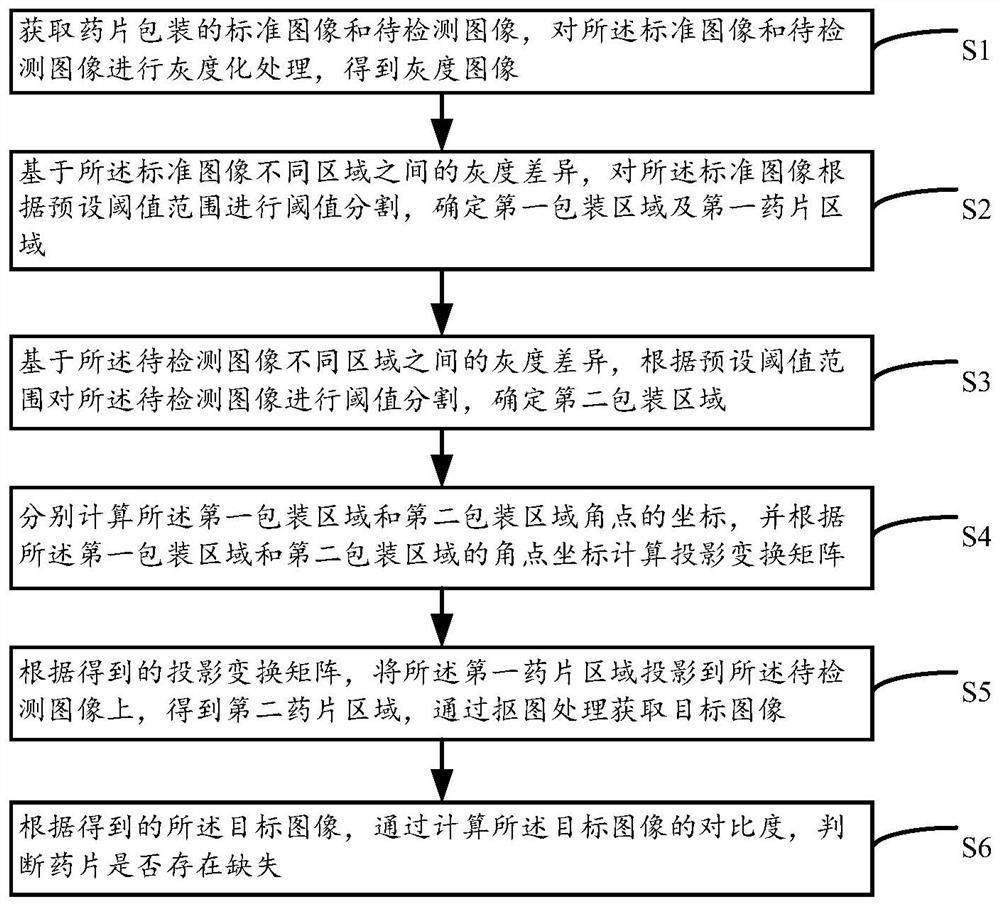

[0074] S1. Obtain a standard image and an image to be detected of the tablet packaging, and perform grayscale processing on the standard image and the image to be detected to obtain a grayscale image;

[0075] S2. Based on the grayscale difference between different areas of the standard image, threshold segmentation is performed on the standard image according to a preset threshold range, and a first packaging area and a first tablet area are determined;

[0076] S3. Based on the grayscale difference between the different areas of the image to be detected, threshold segmentation is performed on the image to be detected a...

Embodiment 2

[0081] An embodiment of the present invention provides a computer-readable storage medium, where an implementation program for information transmission is stored on the computer-readable storage medium, and when the program is executed by the processor 52, the following method steps are implemented:

[0082] S1. Obtain a standard image and an image to be detected of the tablet packaging, and perform grayscale processing on the standard image and the image to be detected to obtain a grayscale image;

[0083] S2. Based on the grayscale difference between different areas of the standard image, threshold segmentation is performed on the standard image according to a preset threshold range, and a first packaging area and a first tablet area are determined;

[0084] S3. Based on the grayscale difference between the different areas of the image to be detected, threshold segmentation is performed on the image to be detected according to a preset threshold range, and a second packaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com