Textile fabric flattening ironing process

An ironing technology for textile fabrics, applied in the field of textile fabric ironing, can solve the problems of inconvenient textile fabrics such as stable pressing, flattening, etc., to achieve the effect of ensuring the ironing effect, easy collection, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The flat ironing process of textile fabrics includes the following steps:

[0029] S1: The fabric is placed, firstly, the textile fabric to be ironed is manually transported to the cabinet by the unwinding roller;

[0030] S2: The fabric is dedusted, and the dust adhering to the surface of the textile fabric is cleaned by the cleaning roller;

[0031] S3: ironing treatment, using an ironing device to shape the cleaned textile fabric, and the ironing temperature is 125-195°C;

[0032] S4: conveying transition, conveying the ironed textile fabric to a winding roller for winding to obtain a finished textile fabric.

Embodiment 2

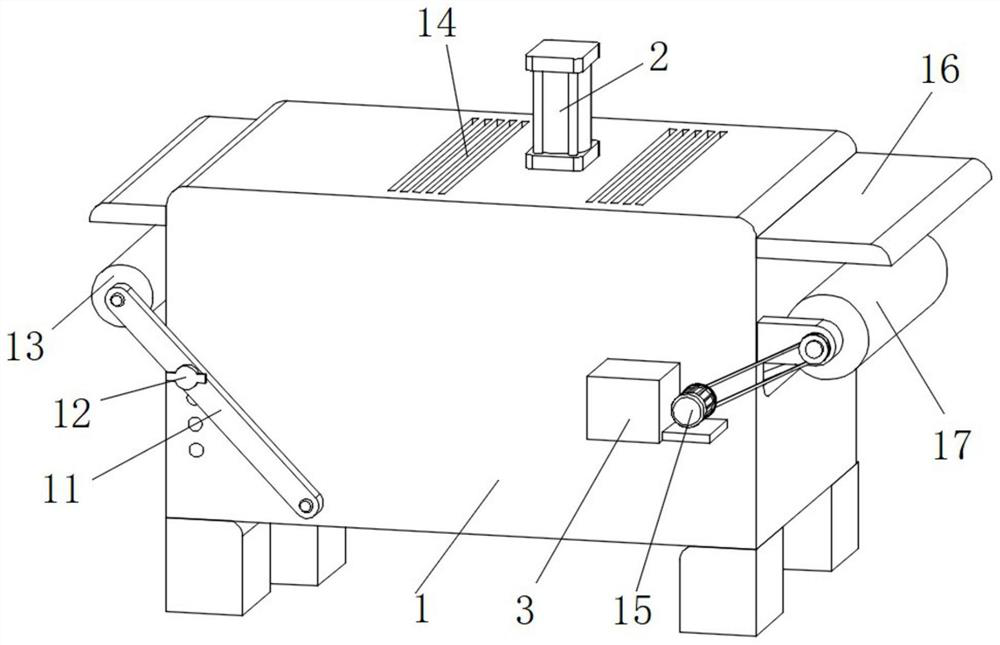

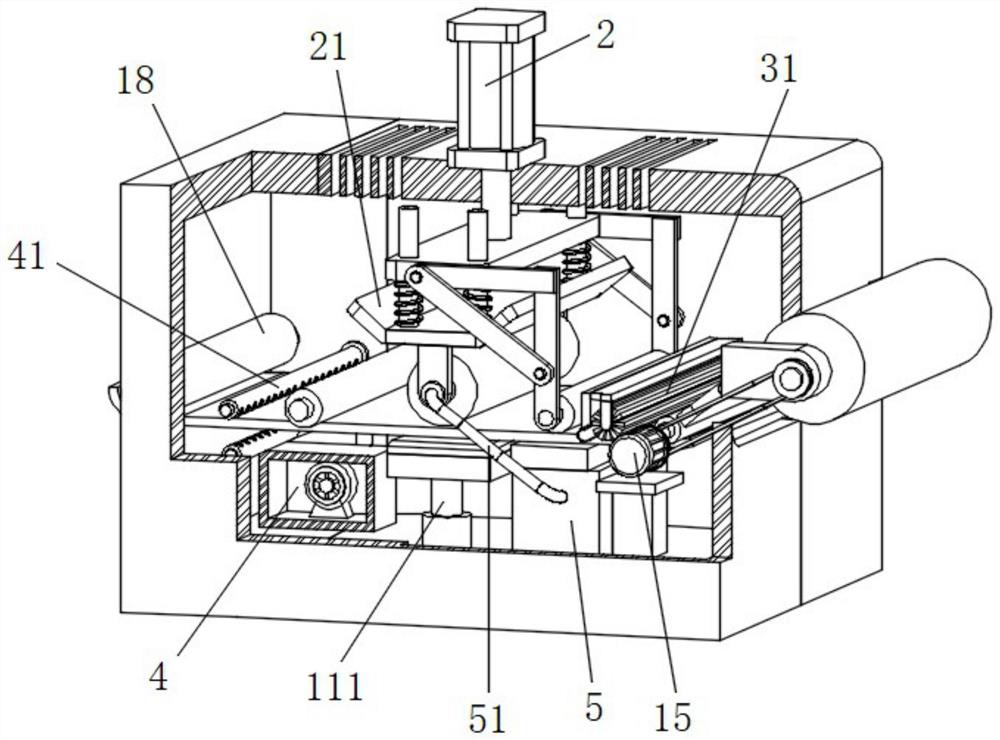

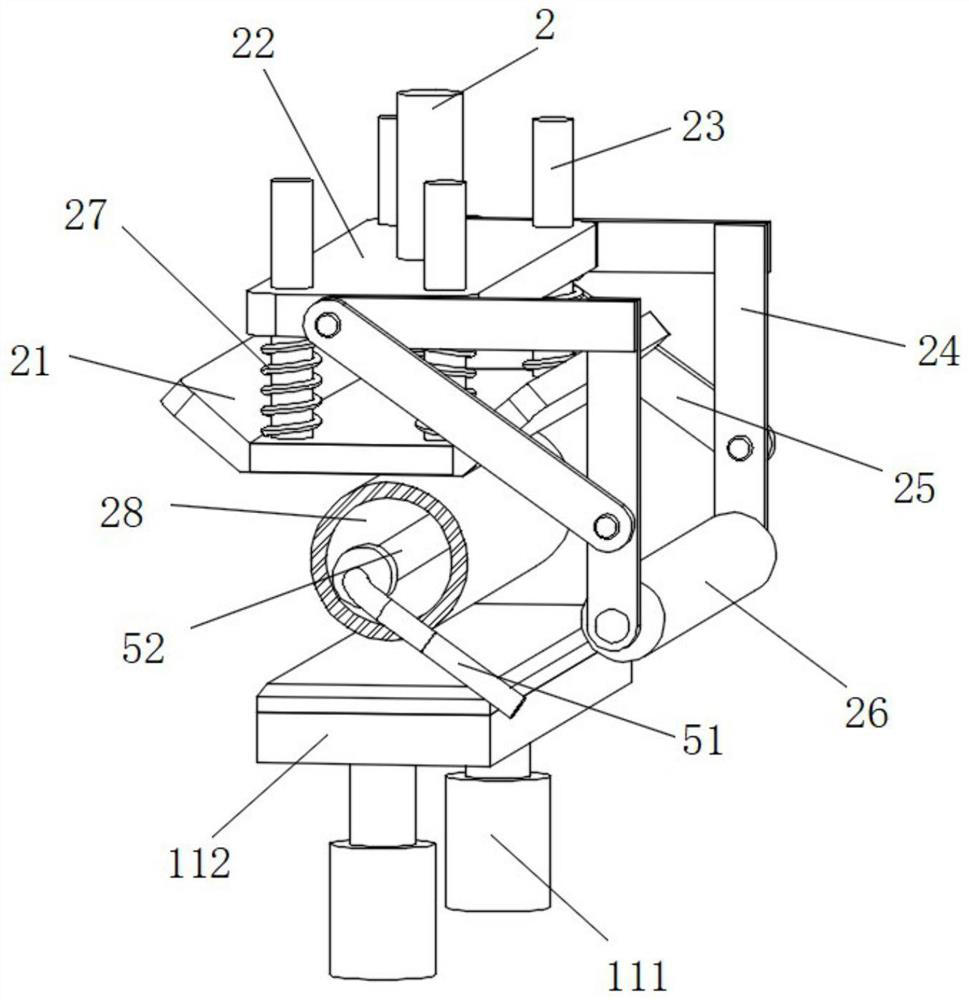

[0034] see Figure 1-5 , the ironing device includes a case 1, an air cylinder 2 and a heating box 5 installed in the case 1. The surface of the case 1 is provided with two opposite support rods 11, and a winding roller 13 is arranged between the two support rods 11. The case 1. A guide roller 17 is provided on the side away from the winding roller 13. Both ends of the case 1 are provided with troughs parallel to the guide roller 17. The case 1 is provided with at least one guide roller 18. The air cylinder 2 is arranged in the case 1. A bearing plate 22 is fixedly connected to the piston rod at the output end of the cylinder 2, and brackets 24 are provided at both ends of the bearing plate 22. A pressure roller 26 is movably provided between the two brackets 24. The bearing plate 22 is movably inserted with at least A screw rod 23, the top of each screw rod 23 is connected with the corresponding inner wall of the chassis 1; and the bottom surface of each screw rod 23 is sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com