Supercritical CO2 extraction process for ganoderma lucidum spore oil

A technology of Ganoderma lucidum spore oil and Ganoderma lucidum spore powder, which is applied in the direction of fat oil/fat production, fat oil/fat refining, and bulk chemical production. Difficult to eliminate and other problems, to achieve the effect of solving the low purity of the separation and purification of Ganoderma lucidum spore oil, meeting consumer needs, and avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

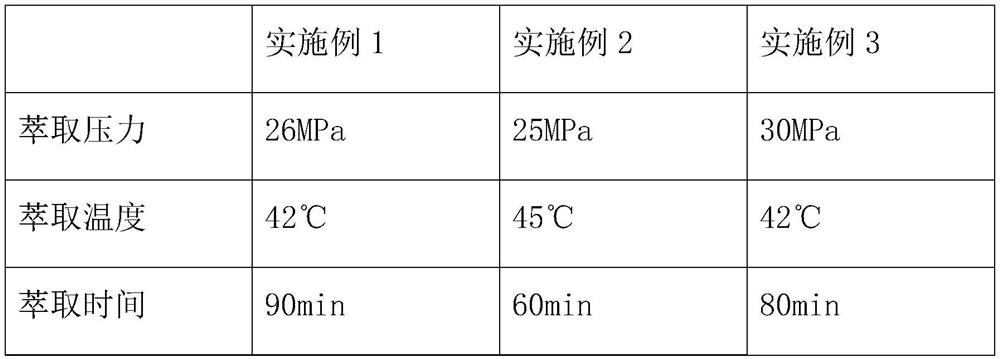

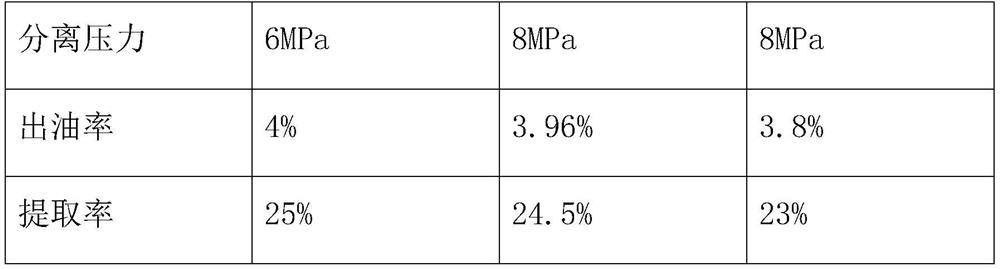

Embodiment 1

[0029] The supercritical CO2 extraction process of Ganoderma lucidum spore oil adopts the following steps:

[0030] S1, select Ganoderma lucidum spore powder for use and pre-process;

[0031] S2, the Ganoderma lucidum spore powder after the pretreatment is placed in the extraction reactor;;

[0032] S3, feed supercritical CO2 fluid, and extract the reaction kettle by heating, and the extraction pressure is 26MPa;

[0033] S4, separate through the separation kettle, and control the separation pressure to be 6MPa;

[0034] S5, start extraction, and release light yellow Ganoderma lucidum spore oil from the outlet of the separation kettle.

[0035] The Ganoderma lucidum spore powder in step S1 is specifically selected from mature and wall-broken Ganoderma lucidum spore powder.

[0036] In step S1, the steps of preprocessing Ganoderma lucidum spore powder are:

[0037] a, firstly, the mature and broken Ganoderma lucidum spore powder is subjected to impurity removal treatment; ...

Embodiment 2

[0047] The supercritical CO2 extraction process of Ganoderma lucidum spore oil adopts the following steps:

[0048] S1, select Ganoderma lucidum spore powder for use and pre-process;

[0049] S2, the Ganoderma lucidum spore powder after the pretreatment is placed in the extraction reactor;;

[0050] S3, feed supercritical CO2 fluid, and extract the reaction kettle by heating, and the extraction pressure is 25MPa;

[0051] S4, separate through the separation kettle, and control the separation pressure to be 8MPa;

[0052] S5, start extraction, and release light yellow Ganoderma lucidum spore oil from the outlet of the separation kettle.

[0053] The Ganoderma lucidum spore powder in step S1 is specifically selected from mature and wall-broken Ganoderma lucidum spore powder.

[0054] In step S1, the steps of preprocessing Ganoderma lucidum spore powder are:

[0055] a, firstly, the mature and broken Ganoderma lucidum spore powder is subjected to impurity removal treatment; ...

Embodiment 3

[0065]The supercritical CO2 extraction process of Ganoderma lucidum spore oil adopts the following steps:

[0066] S1, select Ganoderma lucidum spore powder for use and pre-process;

[0067] S2, the Ganoderma lucidum spore powder after the pretreatment is placed in the extraction reactor;;

[0068] S3, feed supercritical CO2 fluid, and extract the reaction kettle by heating, and the extraction pressure is 30MPa;

[0069] S4, separate through the separation kettle, and control the separation pressure to be 8MPa;

[0070] S5, start extraction, and release light yellow Ganoderma lucidum spore oil from the outlet of the separation kettle.

[0071] The Ganoderma lucidum spore powder in step S1 is specifically selected from mature and wall-broken Ganoderma lucidum spore powder.

[0072] In step S1, the steps of preprocessing Ganoderma lucidum spore powder are:

[0073] a, firstly, the mature and broken Ganoderma lucidum spore powder is subjected to impurity removal treatment;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com