Synthesis method of high-speed, high-tinting-strength and odorless pigment yellow

A synthesis method and coloring power technology, applied in chemical instruments and methods, organic dyes, azo dyes, etc., can solve problems such as high viscosity of feed liquid, low reaction efficiency, and more foaming, and achieve good stability and promote the system stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

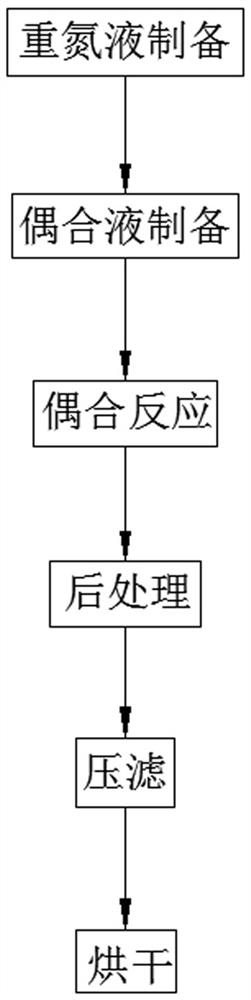

[0032] refer to figure 1 , a high-speed, high tinting strength and no odor-free pigment yellow synthesis method, comprising the following steps:

[0033] S1: Preparation of diazo liquid: The preparation of diazo liquid includes 3,3'-dichlorobenzidine beating and diazotization; the 3,3'-dichlorobenzidine beating is specifically: weigh 1 part of 3,3' - Dichlorobenzidine (100%), adding 2.07 parts of dilute hydrochloric acid solution (20%) and 5.33 parts of water, beating for 1 hour to obtain 3,3'-dichlorobenzidine emulsion; the diazotization is specifically: adding An appropriate amount of ice was used to cool the prepared 3,3'-dichlorobenzidine emulsion to below 0 °C; 1.83 parts of sodium nitrite solution (31%) was slowly added to the 3,3'-dichlorobenzidine emulsion, and added The time is 5min. After adding, ensure that the starch KI test paper is dark blue, and stir well. The stirring time is 1h to ensure sufficient reaction, and the diazo liquid is obtained;

[0034] S2: Pre...

Embodiment 2

[0040] refer to figure 1 , a high-speed, high tinting strength and no odor-free pigment yellow synthesis method, comprising the following steps:

[0041] S1: Preparation of diazo liquid: the preparation of diazo liquid includes 3,3'-dichlorobenzidine beating and diazotization; the 3,3'-dichlorobenzidine beating is specifically: weighing 2 parts of 3,3' - Dichlorobenzidine (100%), adding 4 parts of dilute hydrochloric acid solution (20%) and 10 parts of water, beating for 2 hours to obtain 3,3'-dichlorobenzidine emulsion; the diazotization is specifically: adding An appropriate amount of ice was used to cool the prepared 3,3'-dichlorobenzidine emulsion to below -1°C; 3 parts of sodium nitrite solution (31%) were slowly added to the 3,3'-dichlorobenzidine emulsion, The addition time is 8min. After the addition, ensure that the starch KI test paper is dark blue, and fully stir, and the stirring time is 2h to ensure sufficient reaction, and the diazo liquid is obtained;

[0042]...

Embodiment 3

[0048] refer to figure 1 , a high-speed, high tinting strength and no odor-free pigment yellow synthesis method, comprising the following steps:

[0049] S1: preparation of diazo liquid: the preparation of diazo liquid includes 3,3'-dichlorobenzidine beating and diazotization; the 3,3'-dichlorobenzidine beating is specifically: weighing 3 parts of 3,3' - Dichlorobenzidine (100%), adding 6.21 parts of dilute hydrochloric acid solution (20%) and 15.99 parts of water, beating for 3 hours to obtain 3,3'-dichlorobenzidine emulsion; the diazotization is specifically: adding An appropriate amount of ice was used to cool the prepared 3,3'-dichlorobenzidine emulsion to below -2°C; 5.49 parts of sodium nitrite solution (31%) was slowly added to the 3,3'-dichlorobenzidine emulsion, The addition time is 10min. After the addition, ensure that the starch KI test paper is dark blue, and fully stir, and the stirring time is 3h to ensure sufficient reaction, and the diazo liquid is obtained; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com