Aerated block carrying device based on building engineering construction

A construction engineering and handling device technology, applied in the field of aerated block handling devices for construction engineering, can solve problems such as affecting service life and idling, and achieve the effects of avoiding loss, reducing wheel hub rotation speed, and reducing labor burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

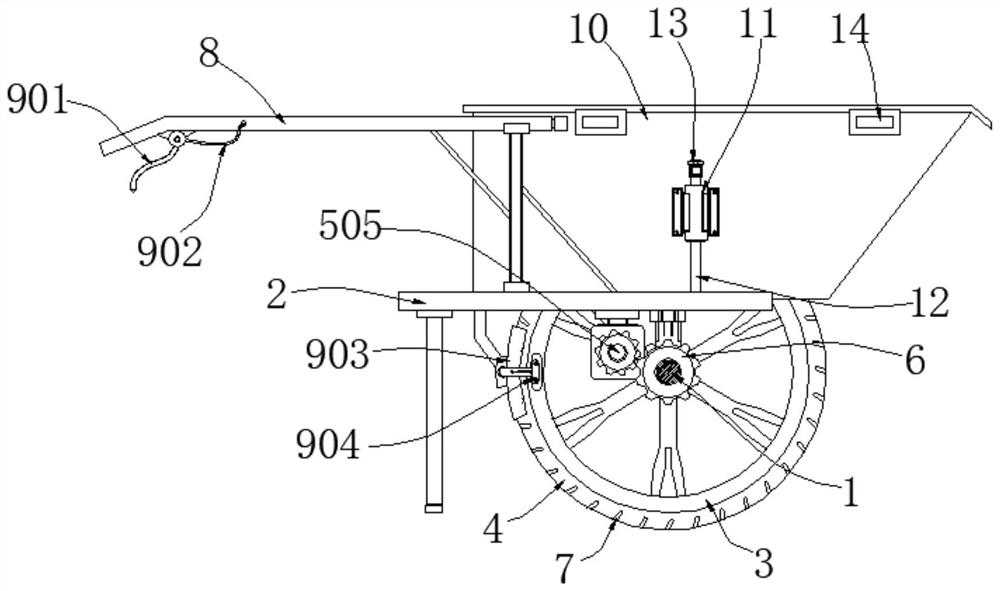

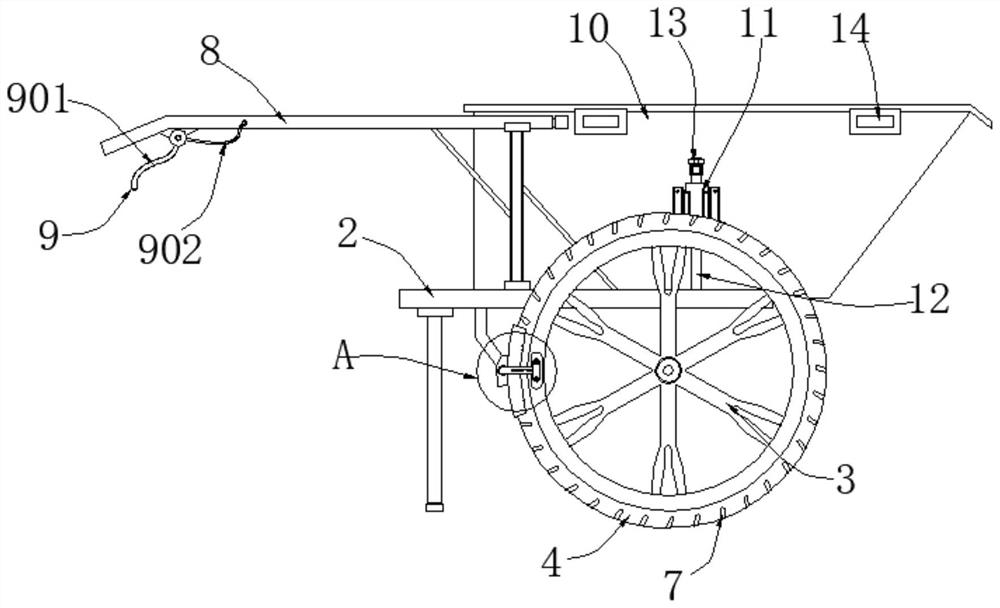

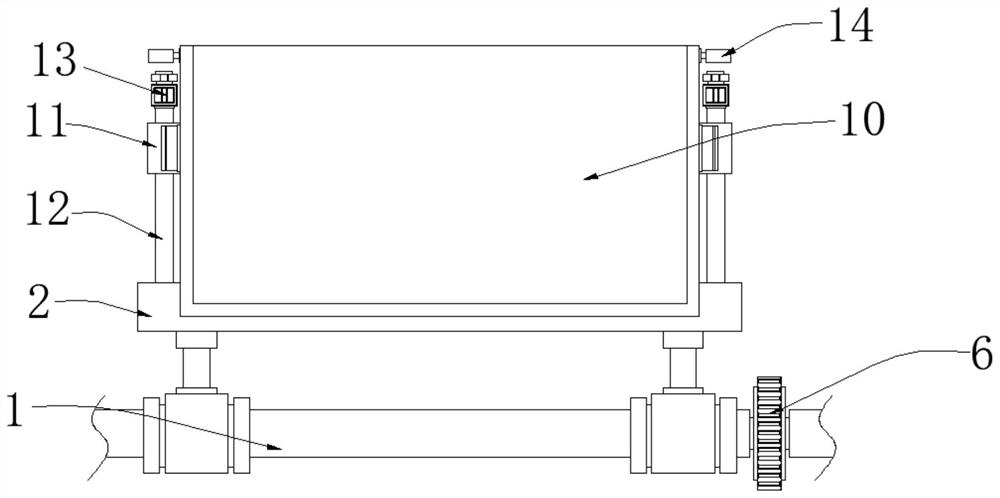

[0030] see Figure 1-5 , the present invention provides a technical solution: based on the air-entraining block handling device for building construction, including an axle 1 and a power assembly 5, the surface of the axle 1 is rotated with a steel frame 2, and both ends of the axle 1 are connected with hubs 3, power The assembly 5 is arranged at the bottom of the steel frame 2. The power assembly 5 includes a battery 501, a servo motor 502, an output shaft 503, a bearing 504, a drive gear 505, a telescopic push rod 506, a square column 507 and a square slot 508. A servo motor 502 is connected to one side, an output shaft 503 is connected to the other side of the servo motor 502, a bearing 504 is rotatably connected to the other side of the output shaft 503, and a drive gear 505 is rotatably connected to the other side of the bearing 504, and the output shaft A telescopic push rod 506 is fixed inside the 503, and a square column 507 is connected to one side of the telescopic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com