Cutting device for rectifier bridge support mold machining

A technology of mold processing and cutting device, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problem of high production cost of cutting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

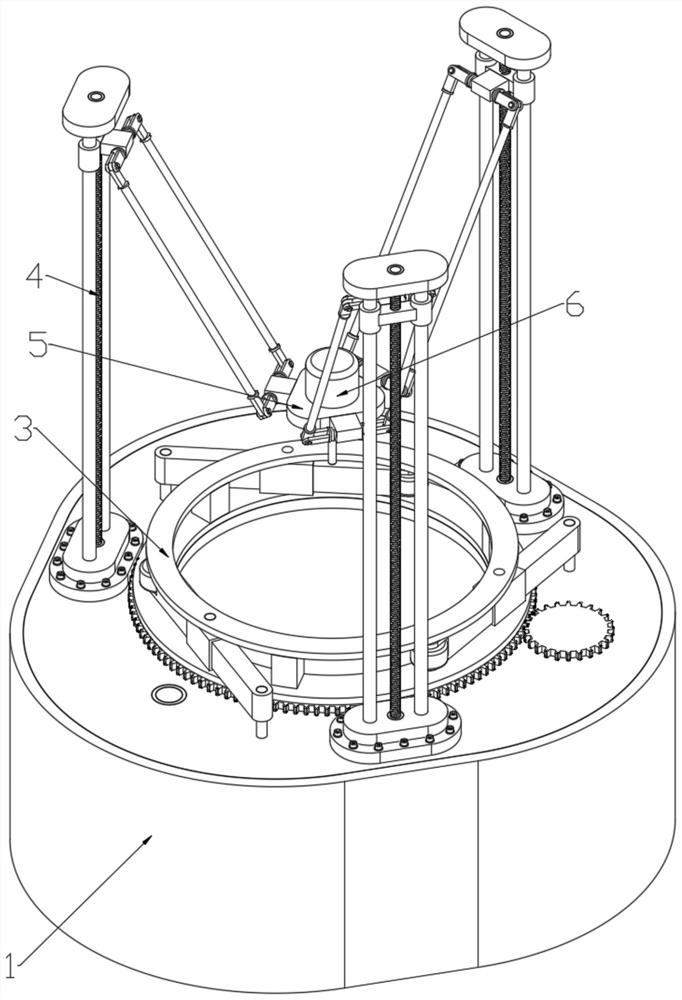

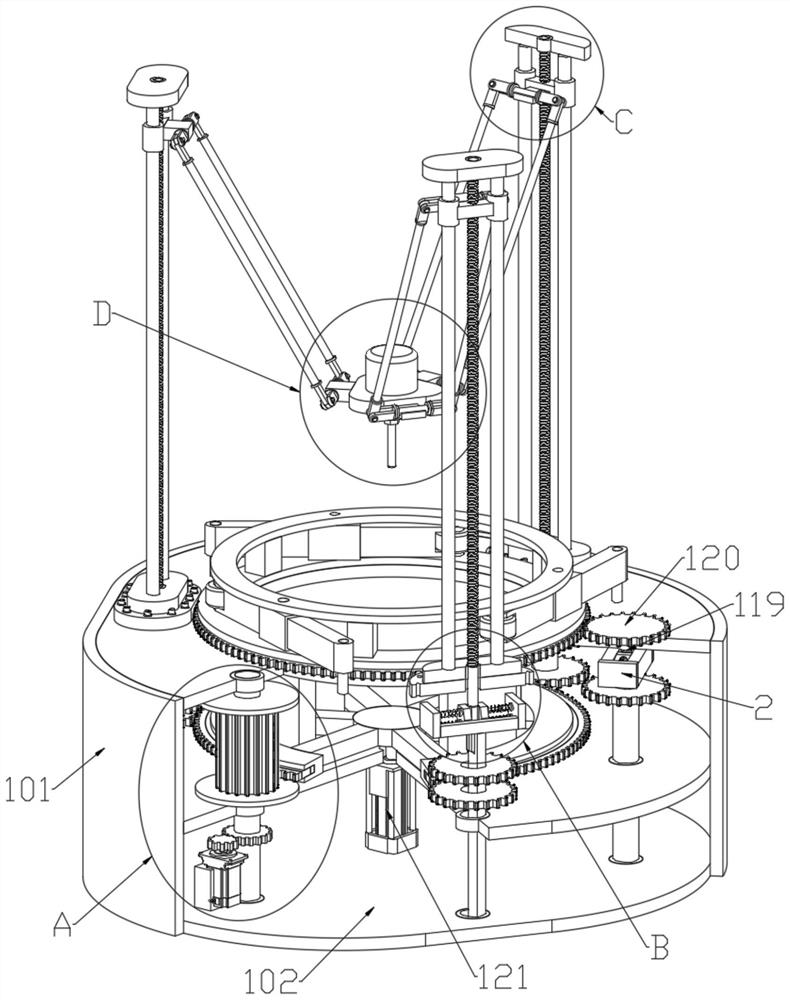

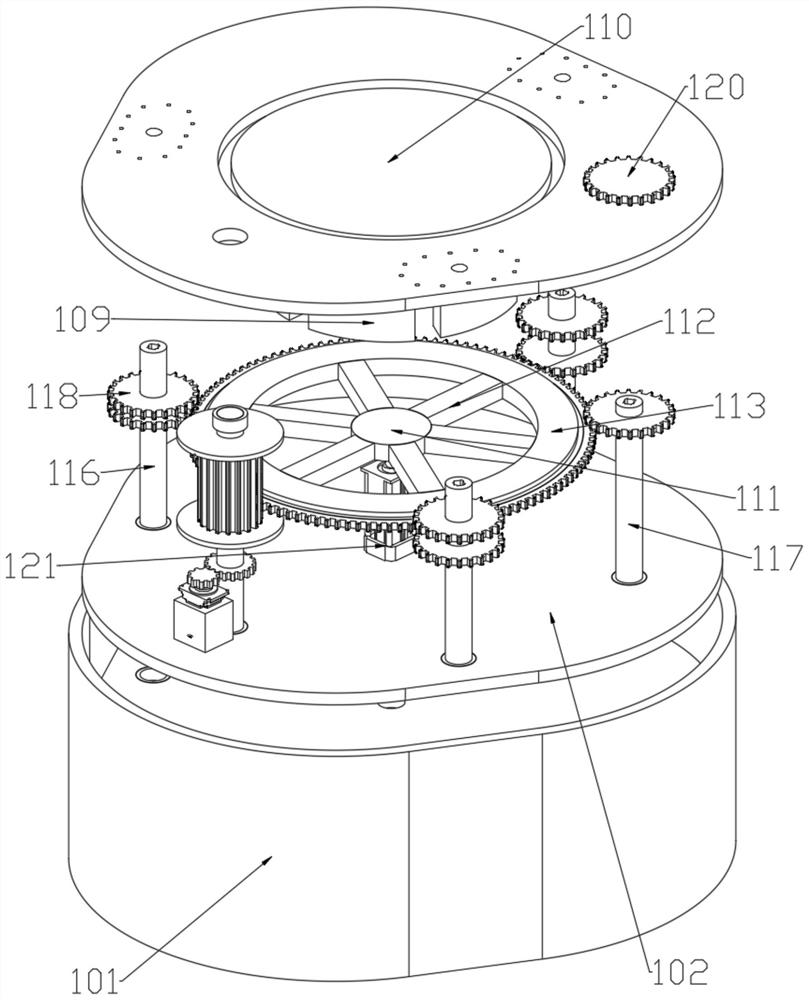

[0032] Example: as Figure 1-10As shown, the present invention provides a cutting device for machining a rectifier bridge bracket mold, including a drive mechanism 1, and the drive mechanism 1 includes three support plates 102 distributed up and down, and two support plates located below A second transmission shaft 117 and three annularly distributed first transmission shafts 116 are arranged on the 102 through the bearing rotation. The first transmission shaft 116 and the second transmission shaft 117 are both provided with a limit mechanism 2, and the uppermost The center of the top of the support plate 102 is provided with a clamping mechanism 3, the outer ring of the clamping mechanism 3 is annularly distributed with three adjustment mechanisms 4, and the three adjustment mechanisms 4 are fixedly installed on the top of the uppermost support plate 102, A base 5 is installed between the three adjusting mechanisms 4 , and a laser cutting device 6 is installed at the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com