Method for eliminating formaldehyde at room temperature

A technology to eliminate formaldehyde and room temperature, applied in separation methods, chemical instruments and methods, heating methods, etc., can solve the problems of high price, high price, and difficulty in popularization and application, and achieve resource saving, waste water reduction, excellent water resistance and humidity resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

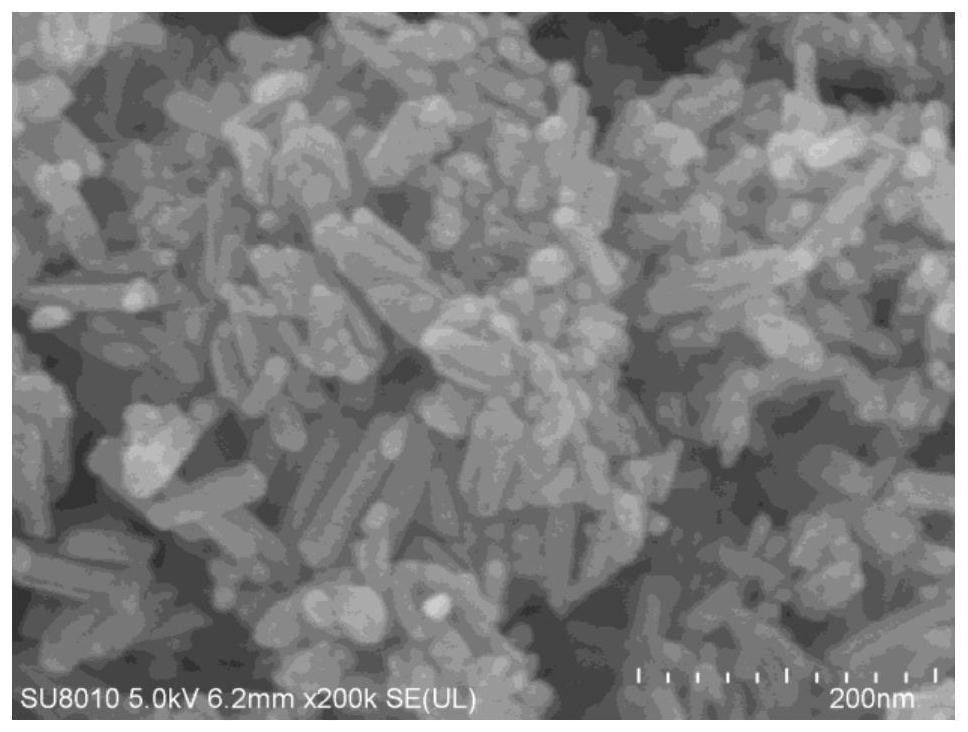

[0039] The potassium permanganate and cerium nitrate solid (the molar ratio of cerium and manganese is 0.05) are ground and mixed uniformly, transferred to the reactor, sealed, crystallized under autogenous pressure conditions at 100 ° C for 2 hours, and the solid obtained after the crystallization is washed. , filtered, and dried to obtain a cerium skeleton doped potassium manganite-type manganese oxide octahedral molecular sieve catalyst. XRD ( figure 1 ) and SEM photographs ( figure 2 ) confirmed the structure and morphology of the samples.

Embodiment 2

[0041] The potassium manganate and the cerium acetate solid (the molar ratio of cerium and manganese is 0.01) are ground and mixed uniformly, transferred to the reaction kettle, sealed, and crystallized for 3 hours under the autogenous pressure condition of 90 ° C, and the obtained solid after the crystallization is washed, Filtration and drying were carried out to obtain a cerium skeleton doped potassium manganite-type manganese oxide octahedral molecular sieve catalyst.

Embodiment 3

[0043] The manganese nitrate and cerium oxide solid (the molar ratio of cerium and manganese is 0.2) are ground and mixed uniformly, transferred to the reaction kettle, sealed, and crystallized under the autogenous pressure condition of 120 ° C for 1 time, the solid obtained after crystallization is washed and filtered. and drying to obtain a cerium skeleton doped potassium manganite-type manganese oxide octahedral molecular sieve catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com