Three-dimensional paper-based micro-fluidic chip for rapidly detecting ferric iron and preparation process of three-dimensional paper-based micro-fluidic chip

A microfluidic chip, ferric technology, applied in measuring devices, laboratory containers, material analysis by observing the impact on chemical indicators, etc., can solve the problem of high requirements for operators, increased detection costs, The operation steps are cumbersome and other problems, so as to save the test time, reduce the detection cost and widen the detection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1 Screening of adsorption diffusion layer filter paper

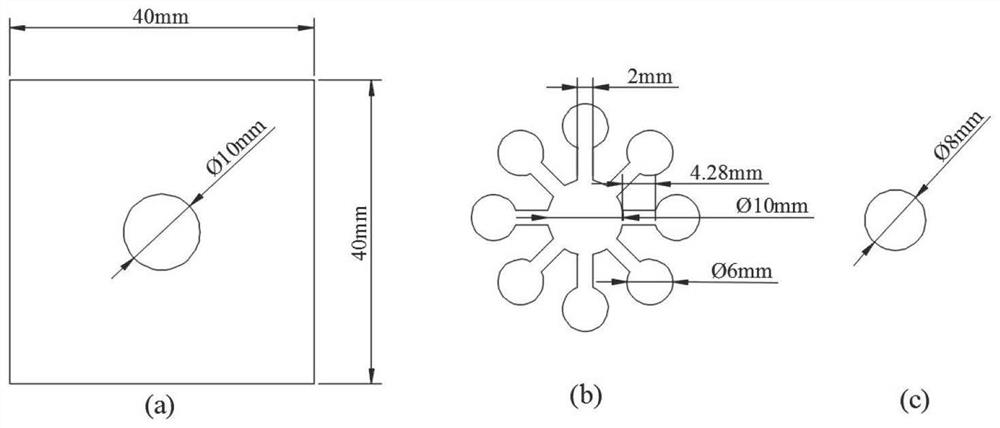

[0062] Step 1: First use a household embossing machine and an octagonal plum-shaped carbon die No.1, No.3 and medium-speed filter paper (commercially available double-circle brand medium-speed filter paper with a diameter of 9 cm) were cut into octagonal plum-shaped paper chips.

[0063] Step 2: Use a household embossing machine and an 8mm round carbon die No.1 is cut into a circular color developing layer of 8mm. The circular color developing layer was soaked in 1 g / L ellagic acid solution for 20 minutes, taken out, placed on a digital display constant temperature heating plate, and dried at 100 °C until there was no moisture. Then follow figure 2 Sequential assembly into a three-dimensional paper-based microfluidic chip.

[0064] Step 3: Add 100 μL of Fe(III) solution with a concentration of 1 mg / L dropwise from the sample hole, wait for the Fe(III) solution to diffuse into the chromogenic layer...

Embodiment 2

[0068] Example 2 Screening of chromogenic layer filter paper

[0069] Step 1: According to the best liquid diffusion and color development selected in Example 1 No.1, then made into plum-shaped paper chips. Reuse home-type embossing machine and carbon tool model will No.1, No.3 and medium speed filter papers are cut into 6mm and 8mm round color developing layers.

[0070] Step 2: Soak all the round color developing layers in 1g / L ellagic acid solution for 20min, take them out, put them on a digital display constant temperature heating plate, and dry them at 100°C until there is no moisture. Then follow figure 2 The sequential assembly method in Table 1 and the combined manner of Table 1 into a three-dimensional paper-based microfluidic chip (Table 1).

[0071] Table 1

[0072]

[0073] Step 3: Add 100 μL of Fe(III) solution with a concentration of 1 mg / L dropwise from the sample addition hole. After the Fe(III) solution diffuses into the chromogenic layer and react...

Embodiment 3

[0075] Embodiment 3 Color development solution concentration screening

[0076] Step 1: according to the experimental results of Examples 1 and 2, cut plum-shaped paper chips ( No.1) and the circular color developing layer ( No.3). Ellagic acid solutions were then prepared at concentrations of 0.0, 0.5, 1.0, 2.0, 4.0, 6.0, 8.0, 10.0, 12.0, 15.0 and 20.0 g / L.

[0077] Step 2: Soak the circular color developing layer in the ellagic acid solution of 0.0, 0.5, 1.0, 2.0, 4.0, 6.0, 8.0, 10.0, 12.0, 15.0 and 20.0g / L for 20min respectively, then take it out, put it on the digital display Dry on a constant temperature heating plate at 100°C until there is no moisture. Then follow figure 2 3D paper-based microfluidic chips are assembled by the sequential assembly method in .

[0078] Step 3: Add 100 μL of Fe(III) solution with a concentration of 1 mg / L dropwise from the sample hole, wait for the Fe(III) solution to diffuse into the chromogenic layer and react with ellagic acid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com