Sealed flue swivel joint and method

A rotary joint and sealed technology, applied in the field of metallurgical equipment, can solve the problems of endangering the health of environmental operators, increasing the load of the dust removal system, and diffuse, etc., achieving good fixing effect, increasing the temperature of exhaust gas, and eliminating dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

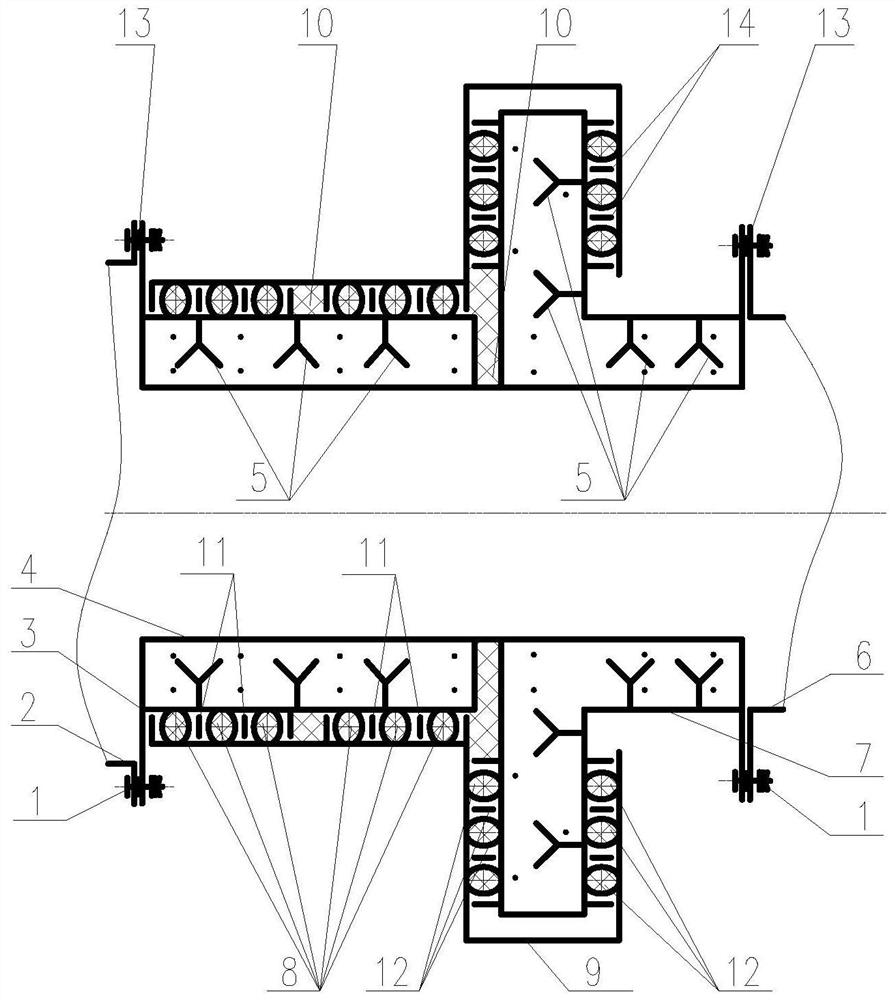

[0035] refer to figure 1 A sealed flue flue rotary joint shown includes a rotary flange 3, a fixed flange 7 and a floating cover 9; the rotary flange 3 is butted with the fixed flange 7, and a sealing packing is provided on the joint surface 10; the floating cover 9 is sleeved on the outer side wall of the rotary flange 3 and the connecting end of the fixed flange 7 and the rotary flange 3; a second sealing mechanism is arranged between the floating cover 9 and the fixed flange 7; the floating cover A first sealing mechanism is arranged along the circumferential direction between 9 and the rotary flange 3 .

[0036] In actual use, the sealed flue rotary joint is connected between the flue 2 on the rotary side of the electric furnace and the fixed flue 6 . When in use, firstly connect the rotary side flue 2 and the rotary flange 3 of the electric furnace detachably through the bolt group 1, and install a gasket 13 on the joint surface of the rotary side flue 2 of the electric ...

Embodiment 2

[0038] refer to figure 1 A sealed flue flue rotary joint shown, on the basis of Embodiment 1, the first sealing mechanism includes a plurality of first sealing rings 8 and a plurality of first floating baffle rings 11; The first sealing ring 8 and the plurality of first floating baffle rings 11 are arranged at intervals; the gap between the first sealing ring 8 and the plurality of first floating baffle rings 11 is provided with a sealing packing 10 .

[0039] In actual use, the function of setting the first floating baffle ring 11 is to make the multiple first sealing rings 8 change according to the actual position, and automatically adjust the compression amount of each first sealing ring 8 to be approximately equal, so as to obtain a good seal At the same time, damage caused by mutual friction between adjacent first sealing rings 8 is avoided.

[0040] In the specific application, the specific floating adjustment process of the first floating baffle ring 11 is as follows: ...

Embodiment 3

[0047] refer to figure 1 In the illustrated sealed flue flue rotary joint, on the basis of Embodiment 1, the second sealing mechanism includes a plurality of second sealing rings 12 and a plurality of second floating baffle rings 14; The second sealing ring 12 is spaced apart from the plurality of second floating baffle rings 14 .

[0048] In actual use, the function of setting the second floating baffle ring 14 is to enable the position of the second sealing ring 12 to be adjusted according to the actual floating position. The specific adjustment process is as follows: when the furnace body tilts, the rotary flange 3 is driven to rotate, and the change of the central axis of the rotary flange 3 drives the floating cover 9 to slide along the outer side wall of the fixed flange 7, so that the relative position of the second sealing ring 12 occurs. Variation, under the floating action of the second floating baffle ring 14, the plurality of second sealing rings 12 disposed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com