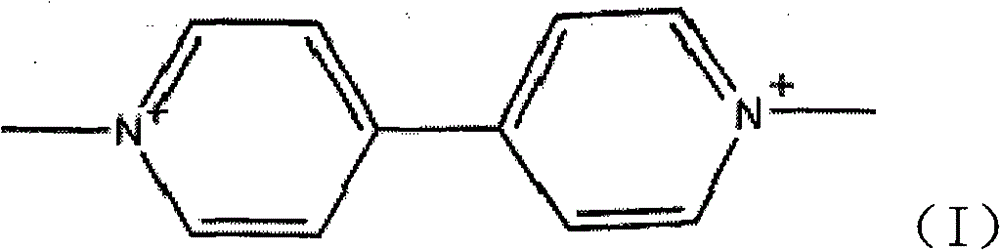

Paraquat solid preparation and preparation method thereof

A technology for solid preparation and paraquat, applied in the field of solid preparation of paraquat and its preparation, can solve the problems of no registration and production of paraquat solid preparation, low feasibility of industrialization, increased possibility of inhalation, etc. Safety risks, ease of recycling, reduction of possible effects of inhalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0046] Production Example 1 of Technical Drug: Production of Concentrated Liquid Paraquat Formulation

[0047] Take 50g of 30% paraquat solution, add 80g of 4A molecular sieve, stir and let it stand for half an hour, filter and remove the molecular sieve to obtain 32.3g of filtrate, which is detected as 47% paraquat concentrate. Molecular sieves are reused after being dried. The filtrate was separated to obtain a paraquat crystalline wet product, and its content was detected to be 61.5%.

manufacture example 2

[0048] Production Example 2 of Active Drug: Production of Concentrated Liquid Paraquat Formulation

[0049] Take 100g of 30% paraquat solution, concentrate under reduced pressure, remove part of the water, add 10g of polymer water-absorbing resin, stir and let it stand for half an hour, filter and remove the polymer water-absorbing resin, the filtrate is 64.6g, and its content is 47 % paraquat concentrate. The polymer water-absorbent resin is reused after being dried. The filtrate was separated to obtain a paraquat crystalline wet product, and its content was detected to be 61.5%.

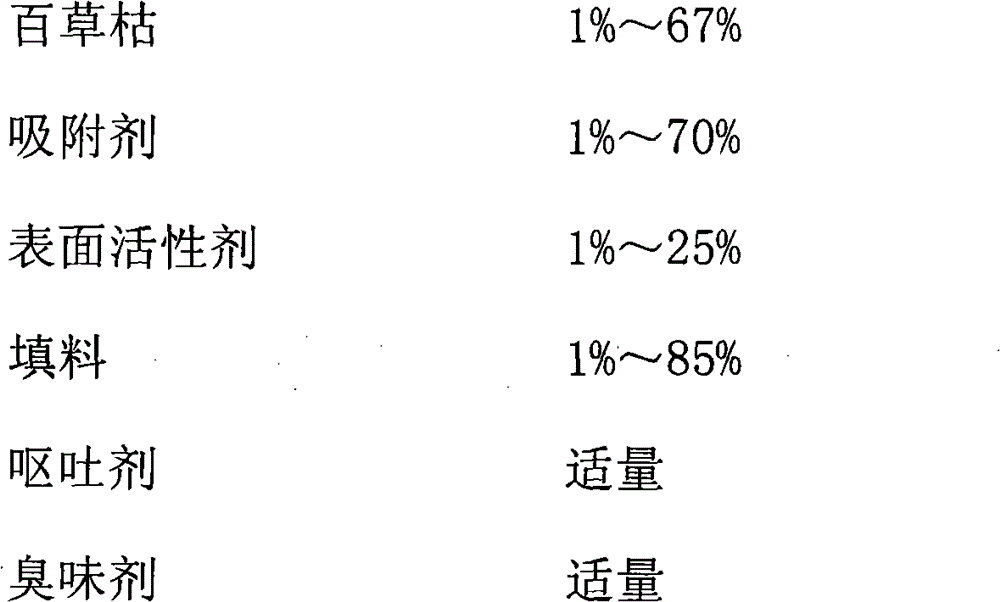

Embodiment 1

[0051] This example is to prepare 12% paraquat water dispersible granules

[0052] Formula: 33.3g of 30% paraquat solution, 10g of adsorbent white carbon black, 20g of starch, 7g of sodium alkylsulfonate, 1.8g of sodium lignin, 3.5g of ammonium sulfate, 0.05g of aminopropyl triazolylpyrimidinone, 4,4'-bipyridine 0.03g, make up to 100g with kaolin. Preparation: Mix white carbon black and add it to the paraquat solution and stir evenly, then add the pre-crushed filler kaolin, ammonium sulfate, emetic aminopropyl triazolyl pyrimidinone, and odorant 4,4'-bipyridine and surfactant sodium alkylsulfonic acid, sodium lignin and starch, mixed evenly, and then granulated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com