Circulating flow air guide device

A technology of air guiding device and circulating flow, which is applied in the direction of dry gas arrangement, lighting and heating equipment, dryer, etc., which can solve the problem of difficult dust removal of dust and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

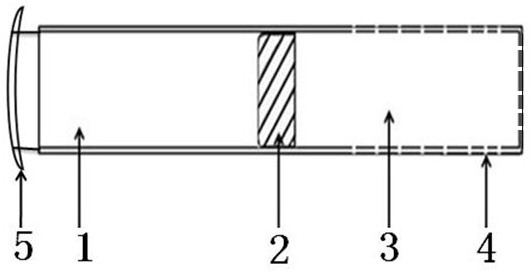

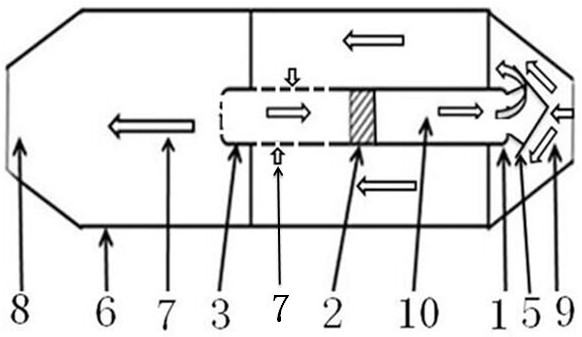

[0036] like figure 1 , figure 2 , image 3 The shown circulating flow air guide device includes an air guide pipe 1, a fan 2, a filter cartridge 3, a guide plate 5, and a bracket.

[0037] The length of the airway 1 is 2000mm, and the diameter is 400mm. The nozzle at the end of the air duct 1 where the fan 2 is installed is the air inlet, and the other end is the exhaust port.

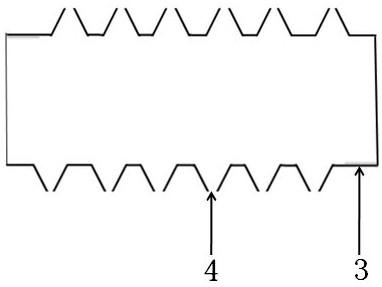

[0038] The filter cartridge 3 is a pipe with one end open and one end closed. The open end of the filter cartridge 3 connected to the fan 2 is an exhaust port; the length of the filter cartridge 3 is 3000mm and the diameter is 400mm. There are ventilation holes 4 on the cylinder body of the filter cartridge 3; the distance between the cone-shaped ventilation holes 4 and the adjacent cone-shaped ventilation holes 4 is 0.5 mm; the diameter of the cone-shaped ventilation holes 4 is 0.1 mm.

[0039]The fan 2 is installed in the pipe of the air duct 1 , and the exhaust port end of the filter cartridge ...

Embodiment 2

[0052] like figure 1 , Figure 4 The shown circulating air guide device includes an air guide pipe 1 , a fan 2 , a filter cartridge 3 , a guide plate 5 , a bracket, and a guide plate 11 .

[0053] The structure of the circulating flow air guide device of the second embodiment is the same as that of the circulating flow air guide device introduced in the first embodiment, and will not be repeated.

[0054] The filter cartridge 3 is a pipe material with open ends at both ends; the nozzle of the filter cartridge 3 connected to the end of the fan 2 is an exhaust port, and the other end is an air inlet.

[0055] The fan 2 is fixed on the air inlet of the air duct 1 , and the exhaust port end of the filter cartridge 3 is fixed on the fan 2 .

[0056] The outer diameter of the guide plate 5 is 80mm larger than the diameter of the air guide pipe, the outer diameter of the guide plate 11 is 150mm larger than that of the filter cartridge 3, the outside diameter of the guide plate 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com