Terminal monitoring device for gas pressure reducing valve

A monitoring device and pressure reducing valve technology, applied in valve device, valve operation/release device, valve details, etc., can solve the problems of unlocked fixing hoop, great harm, insufficient socket depth, etc., to reduce accidents , The effect of preventing gas leakage and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

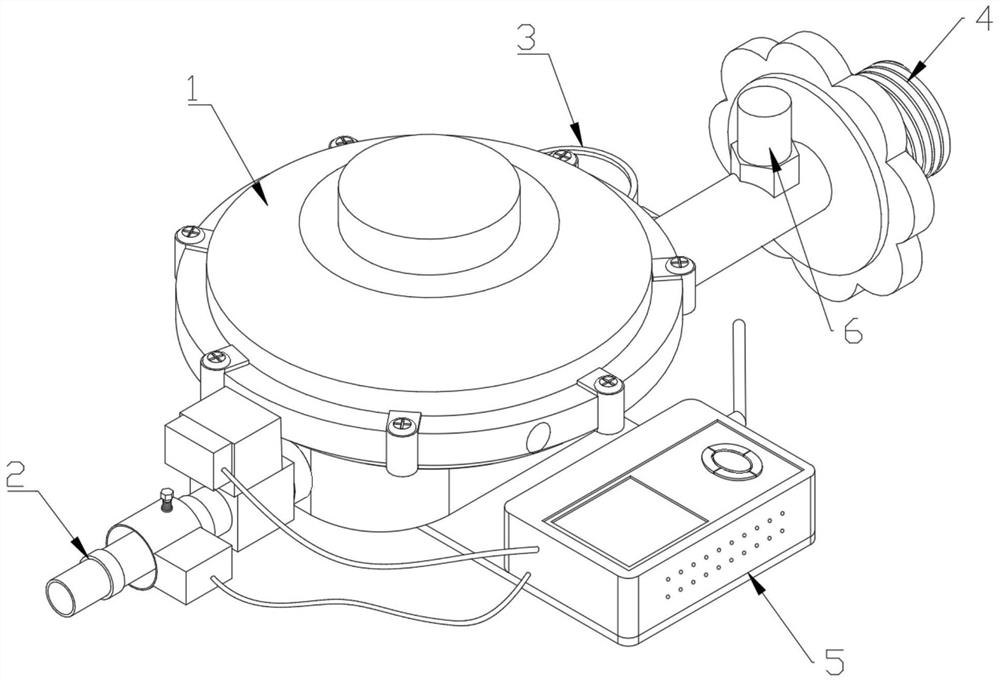

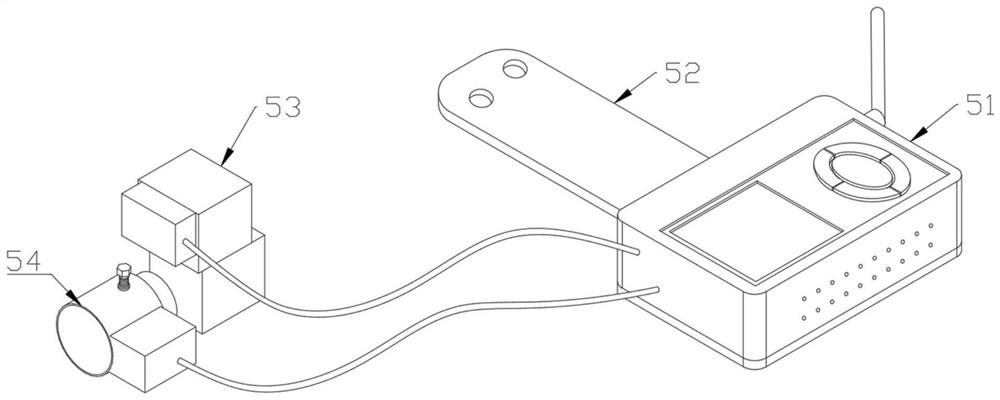

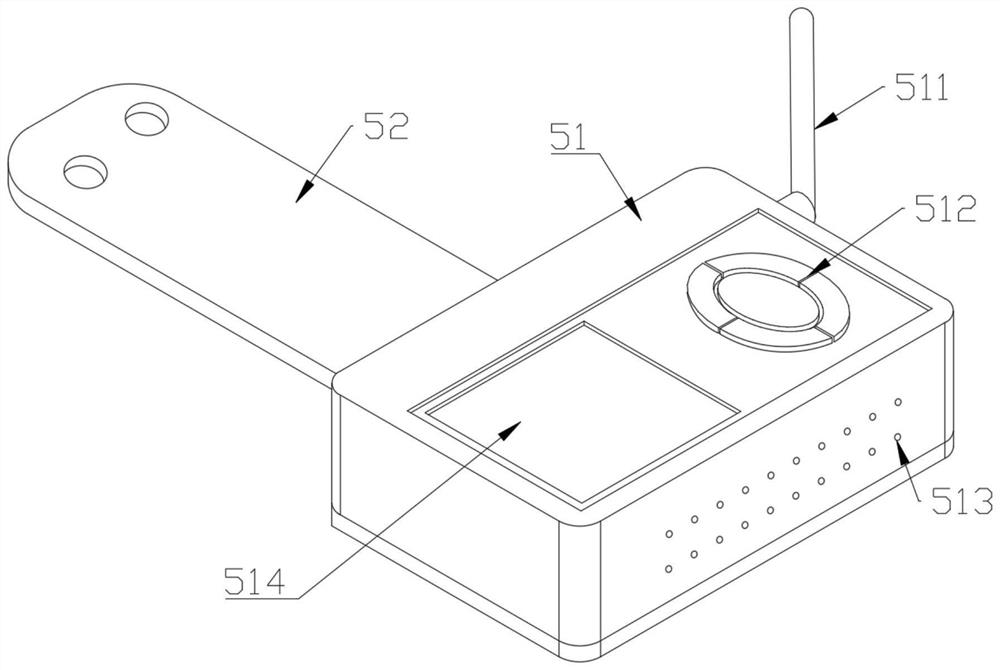

[0025] Example one, by Figure 1-3 and Image 6 Given, the present invention includes a pressure reducing valve body 1, one end of the pressure reducing valve body 1 is connected with one end of an input pipeline, and the other end of the input pipeline is connected with a threaded joint 4, and a pressure gauge 3 and a self-locking module are installed outside the input pipeline. 6. The other opposite end of the main body 1 of the pressure reducing valve is connected with one end of the output pipe, and the other end of the output pipe is connected with a connecting sleeve 2. The connecting sleeve 2 is connected with the external hose, and a clamp is installed to limit the position. The pressure reducing valve A terminal monitoring device 5 is installed at the front end of the main body 1. The terminal monitoring device 5 includes a terminal main body 51, a T-shaped mounting plate 52, an electromagnetic control valve 53 and a locking detection mechanism 54. The bottom of the t...

Embodiment 2

[0027] The second embodiment, on the basis of the first embodiment, is composed of Figure 4-5 Given, the locking detection mechanism 54 includes a connection sleeve 544, one end of the connection sleeve 544 is connected with a detection sleeve 541, and is movably sleeved on the output pipe, and the external thread of the detection sleeve 541 is connected with a plurality of locking screws 543 , and a plurality of locking screws 543 are connected with a rubber block 5431 through the end face of the detection sleeve 541, and a detection module 542 is connected to the outer end of the detection sleeve 541; A plurality of ventilation holes 5411 are opened between 542 and the detection sleeve 541; the gas sensor 5421 is electrically connected to the input of the processing motherboard module; the inner diameter of the detection sleeve 541 is larger than the width of the connection sleeve 2 at the position where the rubber hose is connected and the clamp is installed;

[0028] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com