Pressure vessel

一种压力容器、容纳空间的技术,应用在提高密封性的压力容器领域,能够解决完全粘接状态困难、难以设置紧固件等问题,达到流体泄漏最小化、提高气密性、提高密封性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, a pressure vessel according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

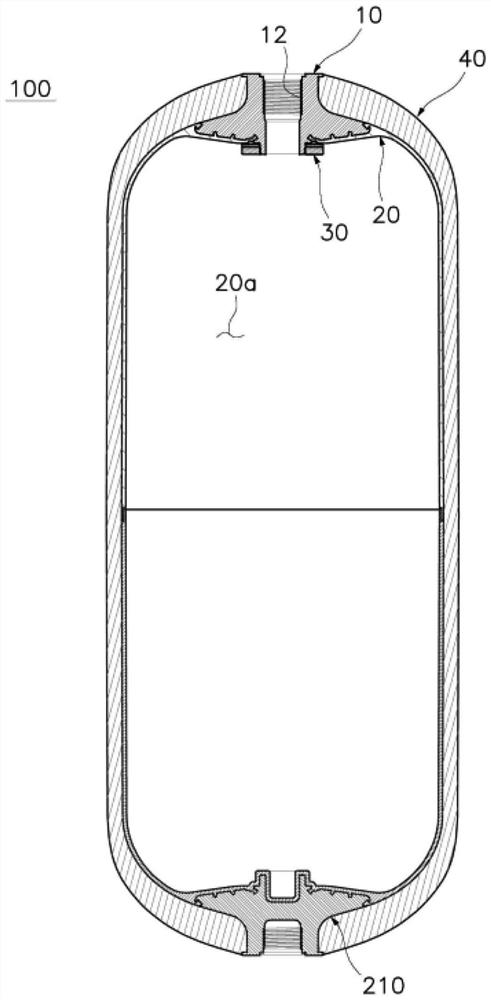

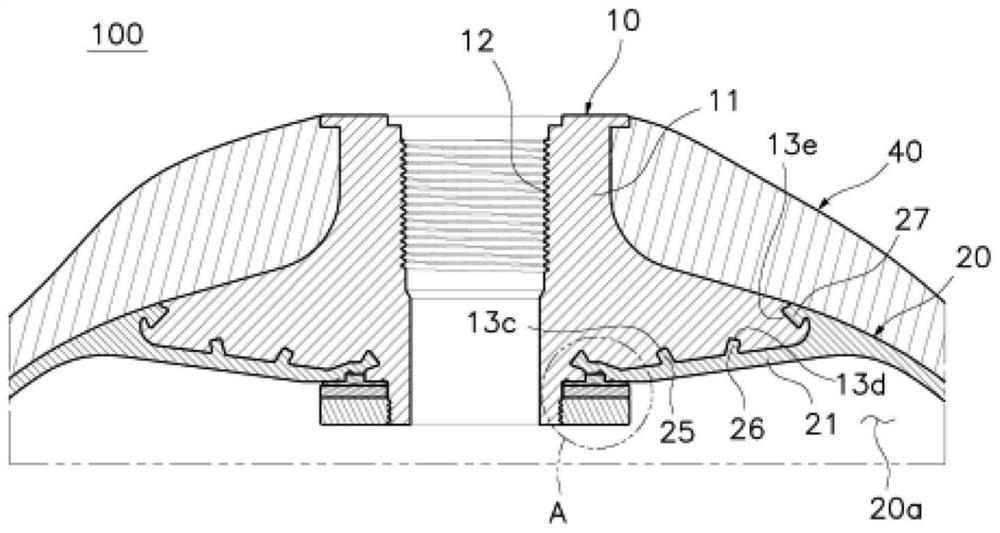

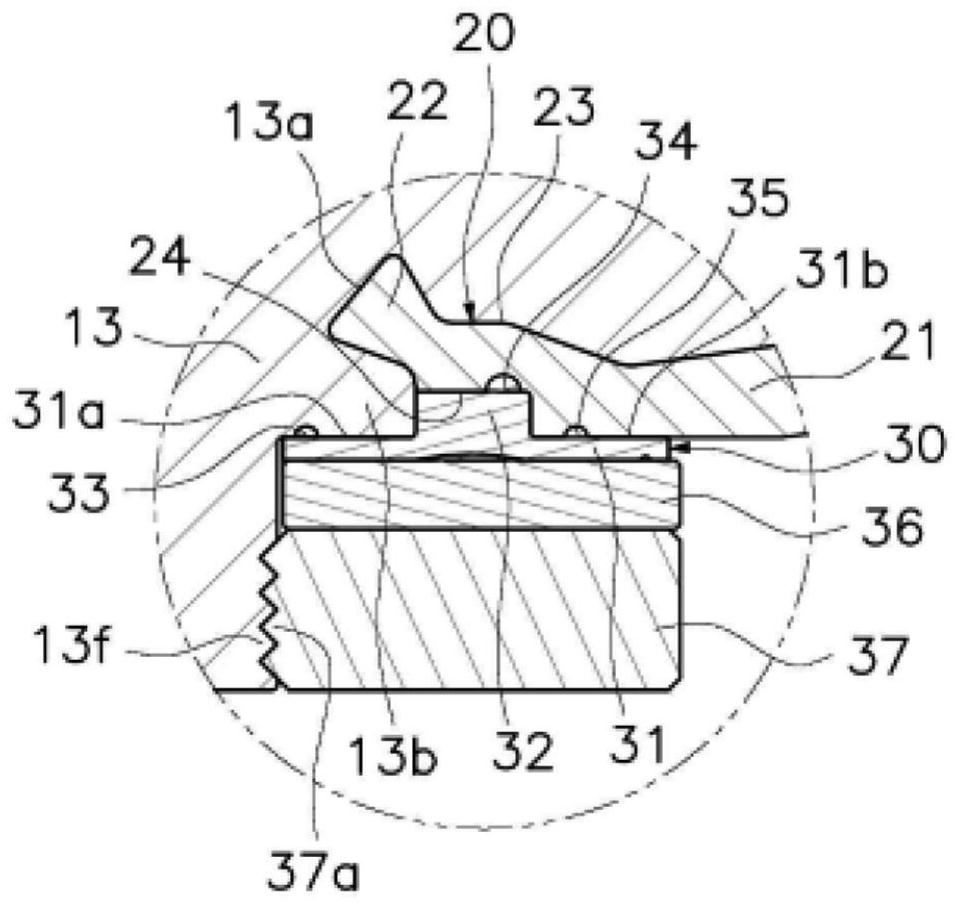

[0029] figure 1 is a cross-sectional view of a pressure vessel showing an embodiment of the present invention; figure 2 is a partial cross-sectional view of a pressure vessel showing an embodiment of the present invention; image 3 Yes figure 2 The "A" part of the enlarged figure.

[0030] like Figure 1 to Figure 3 As shown, the pressure vessel 100 according to an embodiment of the present invention includes a boss portion 10 , an inner lining portion 20 and a sealing portion 30 .

[0031] Here, the pressure vessel 100 is used as a vessel for storing various fluids such as oxygen, natural gas, nitrogen, and hydrogen in the interior, and the fluids can be selectively introduced and discharged repeatedly. At this time, the fluid is stored inside the pressure vessel 100 at a high pressure of 700 bar. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com