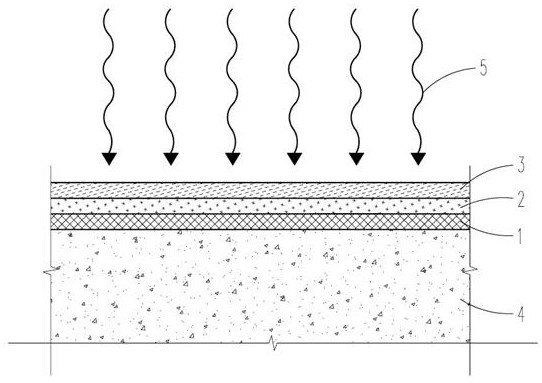

Building radiation cooling coating structure and manufacturing method thereof

A building and coating technology, applied in building components, coatings, reflective/signal coatings, etc., can solve the problems of low sunlight reflectivity, high internal temperature of buildings, high absorption rate, etc., to achieve simple operation and effect. Significant, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The following is the laboratory experiment process, which mainly includes the preparation and implementation process of the coupling agent layer, the preparation and implementation process of the solar spectral radiation total reflection layer, and the preparation and implementation process of the infrared emission layer.

[0062] (1) Preparation and implementation process of coupling agent layer:

[0063] ① Preparation of coupling agent layer:

[0064] 20 ml of hydrolysis catalyst acetic acid was added to the flask, followed by adding 100 ml of deionized water to the flask, and stirring at 25°C, 300 rmp for 10 min. After thorough stirring, KH570 silane with a mass of 60 g, and 30 ml of isopropanol were added until the solution became transparent. Then slowly add 500ml of deionized water to prepare a dilute solution of silane coupling agent.

[0065] ② Implementation of the coupling agent layer:

[0066] First clean the tested aluminum plate and the inside of the foa...

Embodiment 2

[0079]The following is the laboratory experiment process, which mainly includes the preparation and implementation process of the coupling agent layer, the preparation and implementation process of the solar spectral radiation total reflection layer, and the preparation and implementation process of the infrared emission layer.

[0080] (1) Preparation and implementation process of coupling agent layer:

[0081] ① Preparation of coupling agent layer:

[0082] 5 ml of deionized water was added to the flask, followed by 100 ml of absolute ethanol, and stirred for 2 min at 300 rmp at a temperature of 25°C. After fully stirring, KH570 silane with a mass of 20 g was added, and the mixture was stirred at 300 rmp for 10 min to prepare a dilute solution of silane coupling agent.

[0083] ② Implementation of the coupling agent layer:

[0084] First clean the tested aluminum plate and the inside of the foam box, dry at 25°C for 10 minutes, spray a layer of coupling agent on the clean ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com