Package structure and manufacturing method thereof

A packaging structure and manufacturing method technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of unfavorable packaging structure miniaturization, large area, etc., to achieve miniaturization, increase area, improve Yield and Reliability Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above-mentioned and other objects, features and advantages of the present invention more clearly understood, preferred embodiments are given below and described in detail in conjunction with the accompanying drawings. Furthermore, repeated reference symbols and / or wording may be used in different examples of the present invention. These repeated symbols or words are used for the purpose of simplicity and clarity, and are not used to limit the relationship between the various embodiments and / or the described appearance structures.

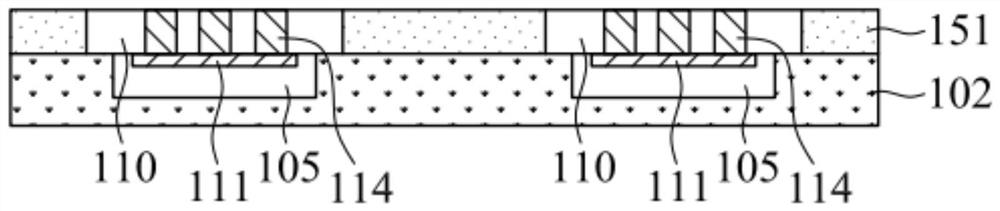

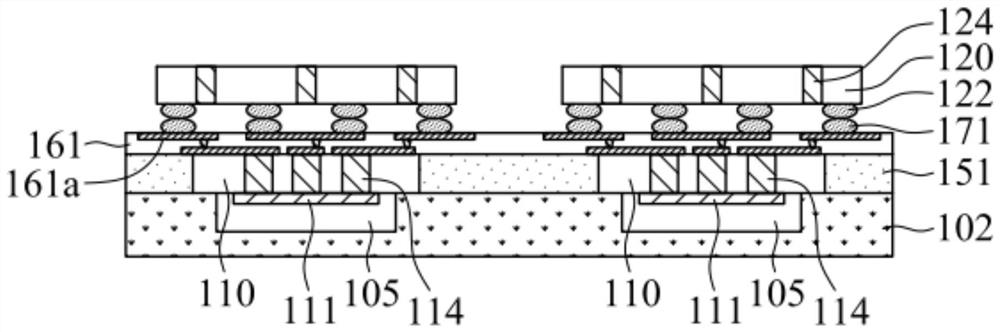

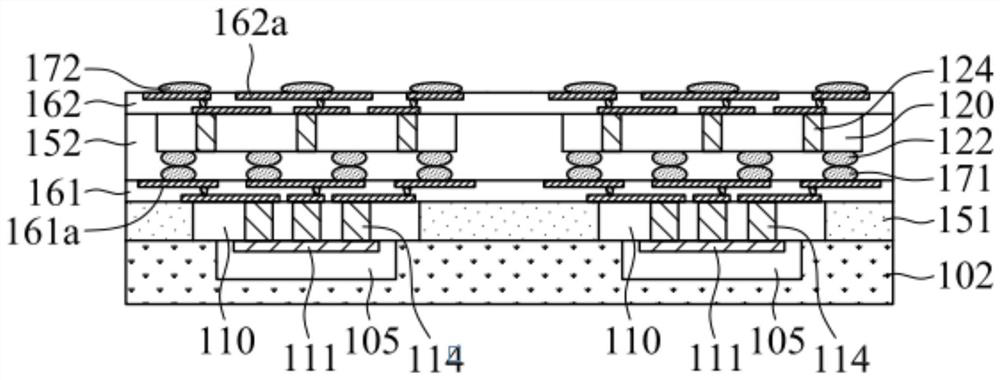

[0020] The present invention provides a package structure and a manufacturing method thereof, Figures 1A to 1F It is a schematic cross-sectional view of the package structure 100 in various stages of the process according to some embodiments of the present invention.

[0021] Please refer to Figure 1A , a substrate 102 having a plurality of notches 105 is provided. Next, corresponding to the positions of these notches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com