Lifting appliance for clamping cylinder cover finished product and clamping method

A technology for finished products and cylinder heads, which is applied in the field of clamping and clamping of finished products of cylinder heads, which can solve the problems of inconvenient operation, low work efficiency and poor safety of clamping tools, and achieve packing and storage Reliable operation, easy to use, and the effect of avoiding scratching the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

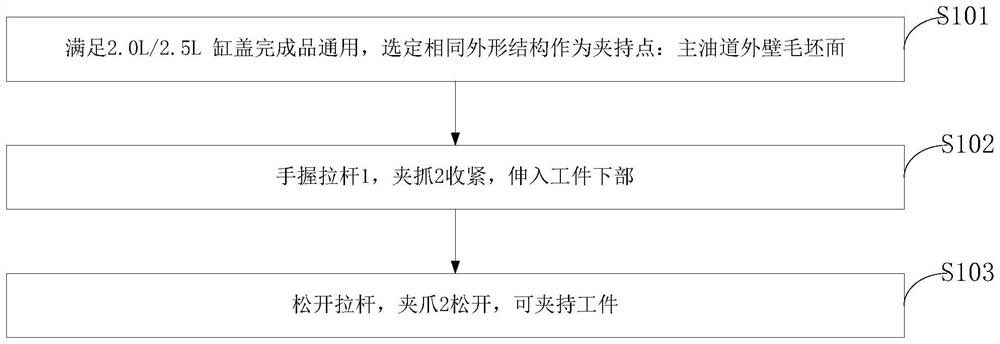

[0040] like figure 1 As shown, the clamping method of the hanger for clamping the finished cylinder head provided by the embodiment of the present invention includes:

[0041] S101, which meets the general requirements of 2.0L / 2.5L cylinder head finished products, and selects the same shape and structure as the clamping point: the rough surface of the outer wall of the main oil passage.

[0042] S102, hold the pull rod 1, tighten the jaw body 2, and extend into the lower part of the workpiece.

[0043] S103 , release the pull rod 1, and release the gripper body 2, so that the workpiece can be clamped.

[0044] In the embodiment of the present invention, after the jaw body 2 is released, it is always under the action of its own weight, and through the structure of the blunt hook structure 9, the outer wall of the main oil passage is just embedded in the groove of the curved portion of the blunt hook structure 9, At this time, the electric hoist can lift up the workpiece (simi...

Embodiment 2

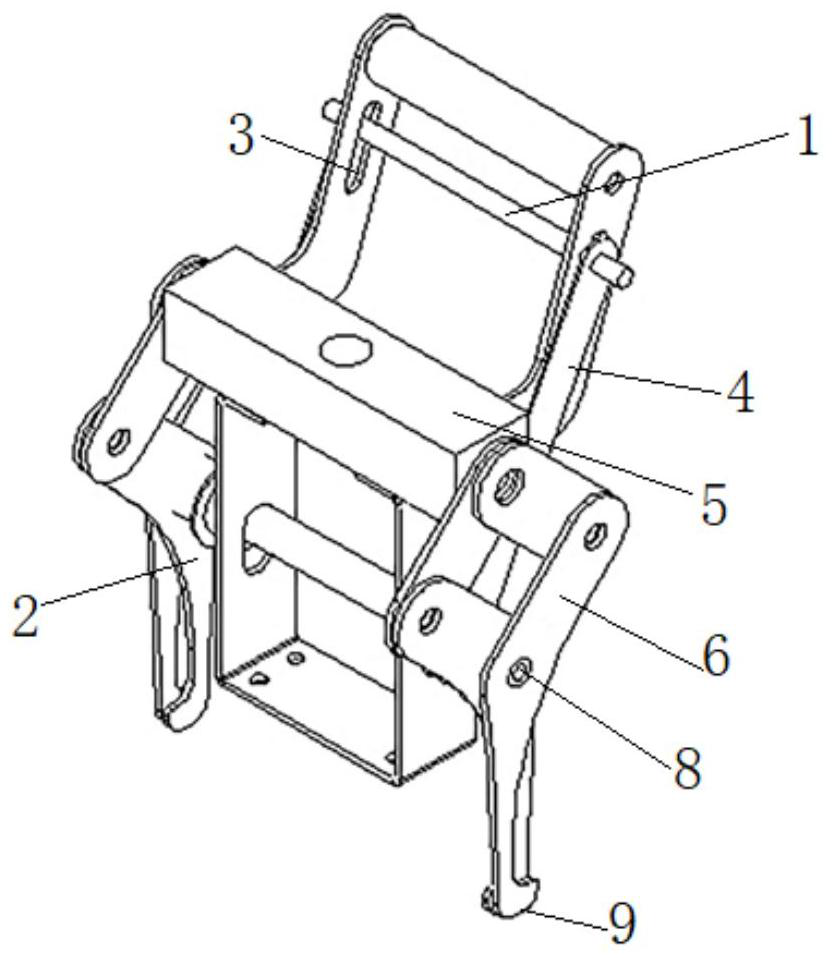

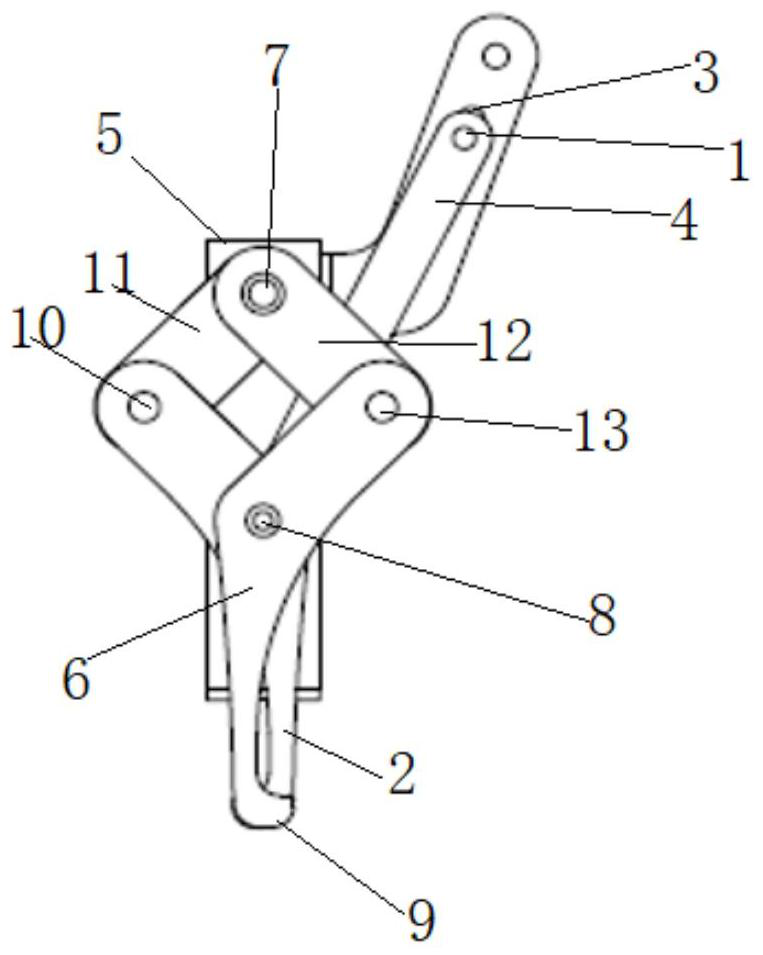

[0046] Use the clamping method of the hanger for clamping the finished cylinder head provided in Example 1, such as Figure 2-Figure 4 As shown, the hanger for clamping the finished cylinder head provided by the embodiment of the present invention includes: a tie rod 1 , a clamping jaw body 2 , a clamping jaw slideway 3 , a clamping jaw intermediate connecting part 4 , and a clamping body 5 .

[0047] The clamping body 5 is provided with a clamping jaw slideway 3; the sliding cavity of the clamping jaw slideway 3 is interspersed with a pull rod 1;

[0048] The tie rod 1 is fixed with a clamping claw intermediate connecting portion 4 through bolts; the clamping claw intermediate connecting portion 4 is connected to the clamping claw body 2 through bolts.

[0049] In a preferred embodiment of the present invention, the lower part of the middle connecting part 4 of the clamping jaw is connected to the bending node part of the clamping jaw body 2 through the rotating shaft 8;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com