Intelligent warehouse logistics method and system

A warehousing logistics and intelligent technology, applied in the field of logistics warehousing, can solve problems such as the inability to intelligently avoid obstacles and the inability to generate optimal moving paths, and achieve the effect of saving sorting time and improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

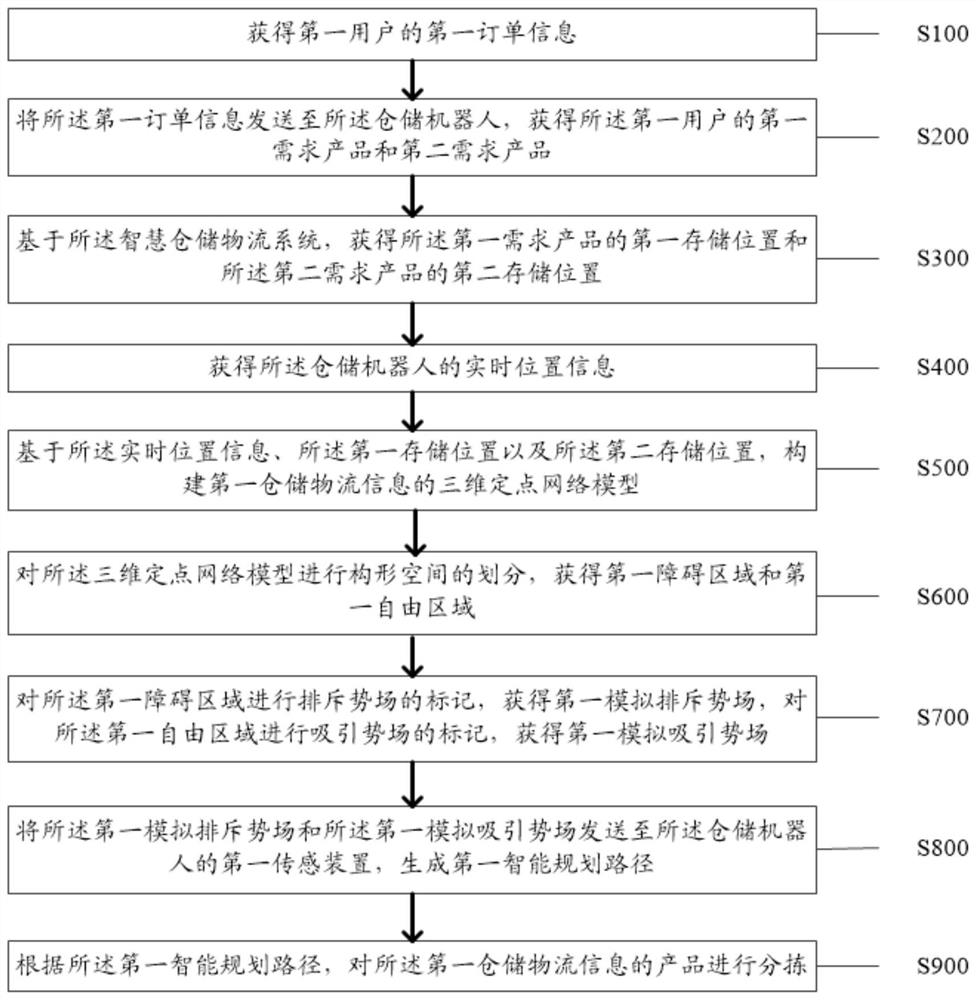

[0023] like figure 1 As shown, the embodiment of the present application provides a smart warehousing and logistics method, wherein the method is applied to a smart warehousing and logistics system, and the system is communicatively connected with a warehousing robot, and the method further includes:

[0024] Step S100: obtaining the first order information of the first user;

[0025] Specifically, smart warehousing is a warehousing management concept, which is smart logistics realized through informatization, Internet of Things, cloud computing and mechatronics, thereby reducing warehousing costs, improving operational efficiency, and enhancing warehousing management capabilities. Its application purpose is to ensure the speed and accuracy of data input in all aspects of cargo warehouse management, to ensure that enterprises can grasp the real data of inventory in a timely and accurate manner, and to maintain and control enterprise inventory reasonably. By applying smart war...

Embodiment 2

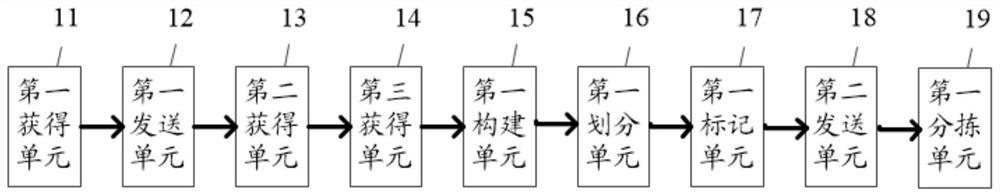

[0079] Based on the same inventive concept as the smart warehousing and logistics method in the foregoing embodiment, the present invention also provides a smart warehousing and logistics system, such as figure 2 As shown, the system includes:

[0080] The first obtaining unit 11: the first obtaining unit 11 is used to obtain the first order information of the first user;

[0081] The first sending unit 12: the first sending unit 12 is used to send the first order information to the warehouse robot, and obtain the first demanded product and the second demanded product of the first user;

[0082] Second obtaining unit 13: The second obtaining unit 13 is configured to obtain the first storage location of the first demanded product and the second storage location of the second demanded product based on the smart warehousing and logistics system;

[0083] The third obtaining unit 14: the third obtaining unit 14 is used to obtain the real-time position information of the warehous...

Embodiment 3

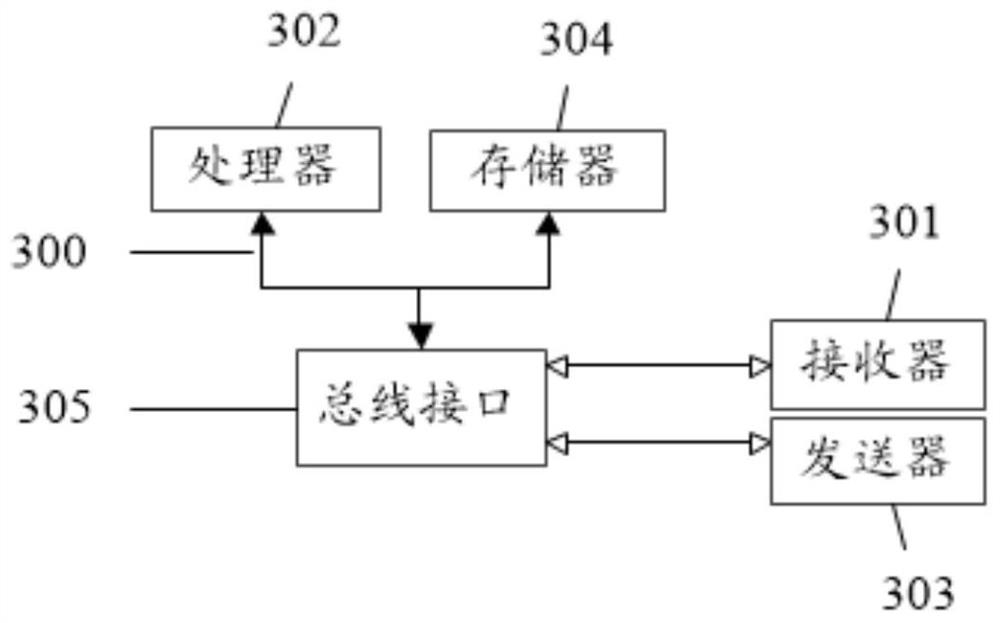

[0123] Reference below image 3 to describe the electronic device of the embodiments of the present application.

[0124] image 3 A schematic structural diagram of an electronic device according to an embodiment of the present application is shown.

[0125] Based on the inventive concept of a smart warehousing and logistics method implemented in the aforementioned example, the present invention also provides a smart warehousing and logistics system, on which a computer program is stored, and when the program is executed by a processor, the aforementioned smart warehousing and logistics system is implemented. The steps of any method of the system.

[0126] Among them, in image 3 In the bus architecture (represented by bus 300 ), bus 300 may include any number of interconnected buses and bridges, bus 300 will include one or more processors represented by processor 302 and various types of memory represented by memory 304 circuits are linked together. The bus 300 may also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com