Novel silver paste spraying process for laminated pole piece of capacitor

A capacitor and silver paste technology, which is applied to fixed capacitor electrodes, fixed capacitor parts, coatings, etc., can solve the problems of different thicknesses of silver paste coatings, reduce material usage and stack thickness, and achieve excellent capacity, Excellent ESR performance, the effect of reducing the amount of material used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

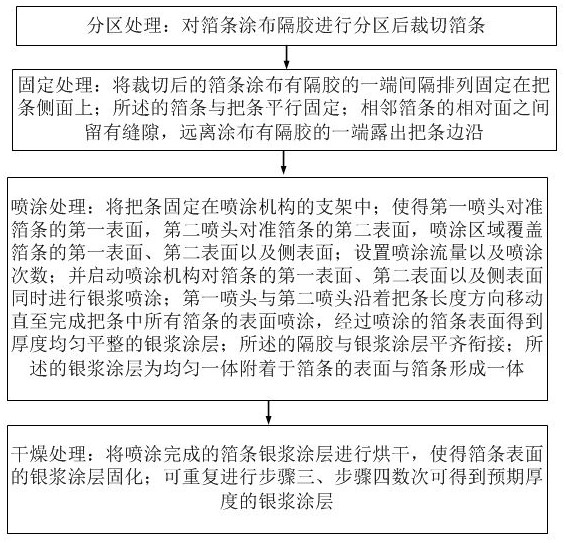

[0060] S1: Partitioning treatment: After partitioning the foil strip 1 with the separator 102, the foil strip 1 is cut.

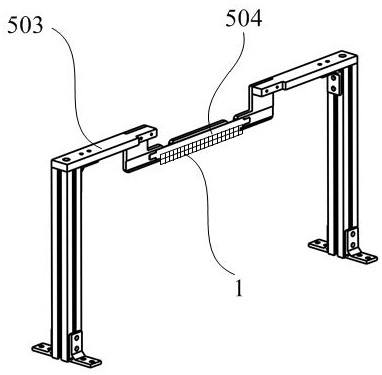

[0061] S2: Fixing treatment: one end of the cut foil strip 1 coated with the spacer 102 is arranged at intervals and fixed on the side of the strip 504; the foil strip 1 is fixed in parallel with the strip 504; A gap is left between the opposite surfaces, and the edge of the handle bar 504 is exposed from the end away from the end coated with the spacer glue 102 .

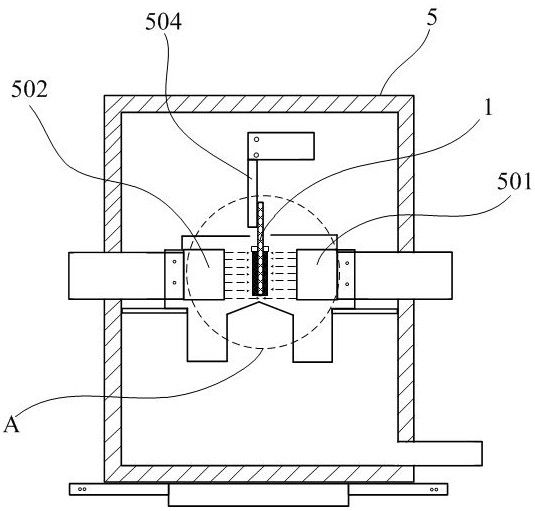

[0062] S3: Spraying treatment process: the strip 504 will be fixed in the bracket 503 of the spraying mechanism 5; , the spraying area 6 covers the first surface 1011, the second surface 1012 and the side surface 1013 of the foil strip 1; the number of sprays is set to 1; the air pressure of the first spray head 501 and the second spray head 502 is 0.4MP6, so The speed of the described spraying mechanism 5 moving along the bar 504 is 10 cm / s. And start the spraying mechanism 5 to spray silver ...

Embodiment 2

[0066] S1: Partitioning treatment: After partitioning the foil strip 1 with the separator 102, the foil strip 1 is cut.

[0067]S2: Fixing treatment: one end of the cut foil strip 1 coated with the spacer 102 is arranged at intervals and fixed on the side of the strip 504; the foil strip 1 is fixed in parallel with the strip 504; A gap is left between the opposite surfaces, and the edge of the handle bar 504 is exposed from the end away from the end coated with the spacer glue 102 .

[0068] S3: Spraying treatment process: the strip 504 will be fixed in the bracket 503 of the spraying mechanism 5; , the spraying area 6 covers the first surface 1011, the second surface 1012 and the side surface 1013 of the foil strip 1; the number of sprays is set to 2 times; the air pressure of the first spray head 501 and the second spray head 502 is 0.7MP6, so The speed of the described spraying mechanism 5 moving along the bar 504 is 4 cm / s. And start the spraying mechanism 5 to spray sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com