Adjustable confluence clamp

An adjustable, clamp technology, applied in the direction of clamp connection conductor connection, transportation and packaging, wire wound connectors, etc., can solve the complex structure of the cable crimp body, reduce the current carrying capacity of the system, increase the contact resistance point, etc. problems, to achieve the effect of simple structure, reduced weight, and increased current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

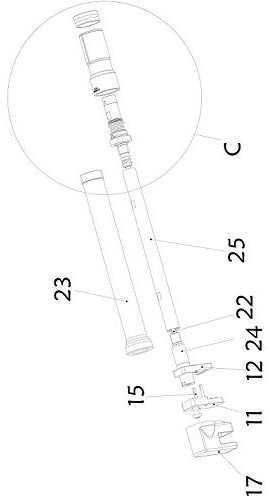

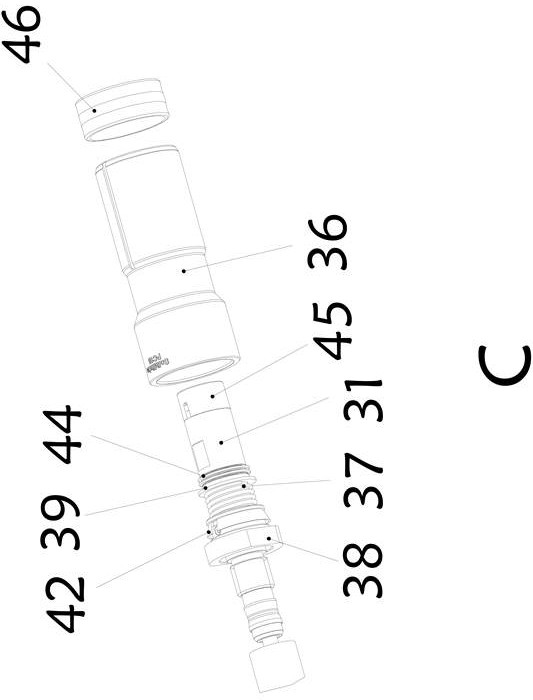

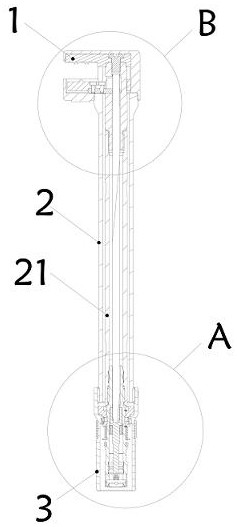

[0022] like Figure 1-5 As shown, an adjustable bus clamp includes a clamp body 1, a clamp arm 2 and a cable connection body 3. The clamp body 1 is detachably connected to the front end of the clamp arm 2, and the cable The connecting body 3 is detachably connected to the rear end of the clamp arm 2 coaxially.

[0023] like Figure 5 As shown, the clamp body 1 includes a front fixed clamp head 11 and a rear movable clamp head 12, the front fixed clamp head 11 and the rear movable clamp head 12 are arranged in an insulating sleeve 17, and the front fixed clamp head 11 A clamping space is formed with the rear movable clamp head 12 . The rear movable clamp head 12 includes a movable clamp plate 13 and a moving block 14 , and the movable clamp plate 13 is fixedly connected with one end of the moving block 14 .

[0024] The movable clamp plate 13 is provided with a guide hole (not shown), and the front fixed clamp head 11 is provided with a guide pin 15. When the movable clamp p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com