Protection structure and protection method of switch cabinet

A protection structure and switchgear technology, applied in the field of switchgear, can solve the problem of unprotected internal components, and achieve the effects of moisture-proof protection, avoidance of ash and water, and good heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

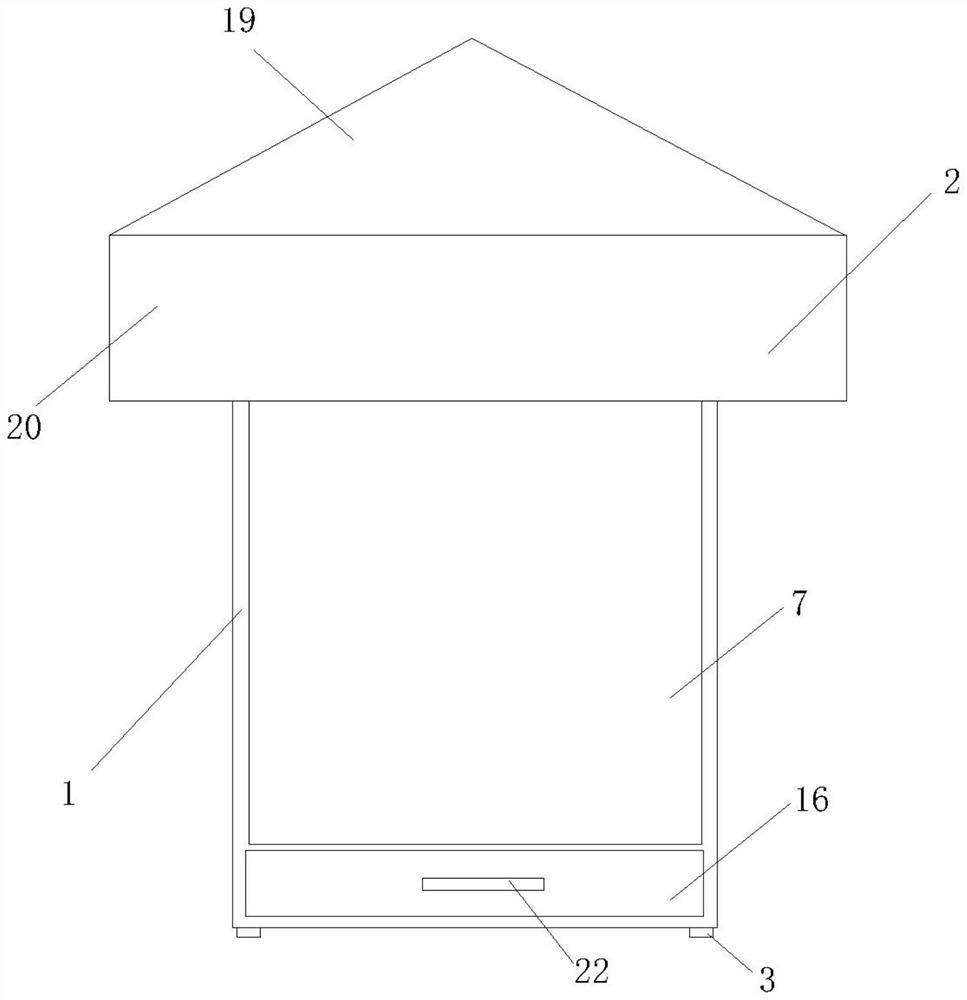

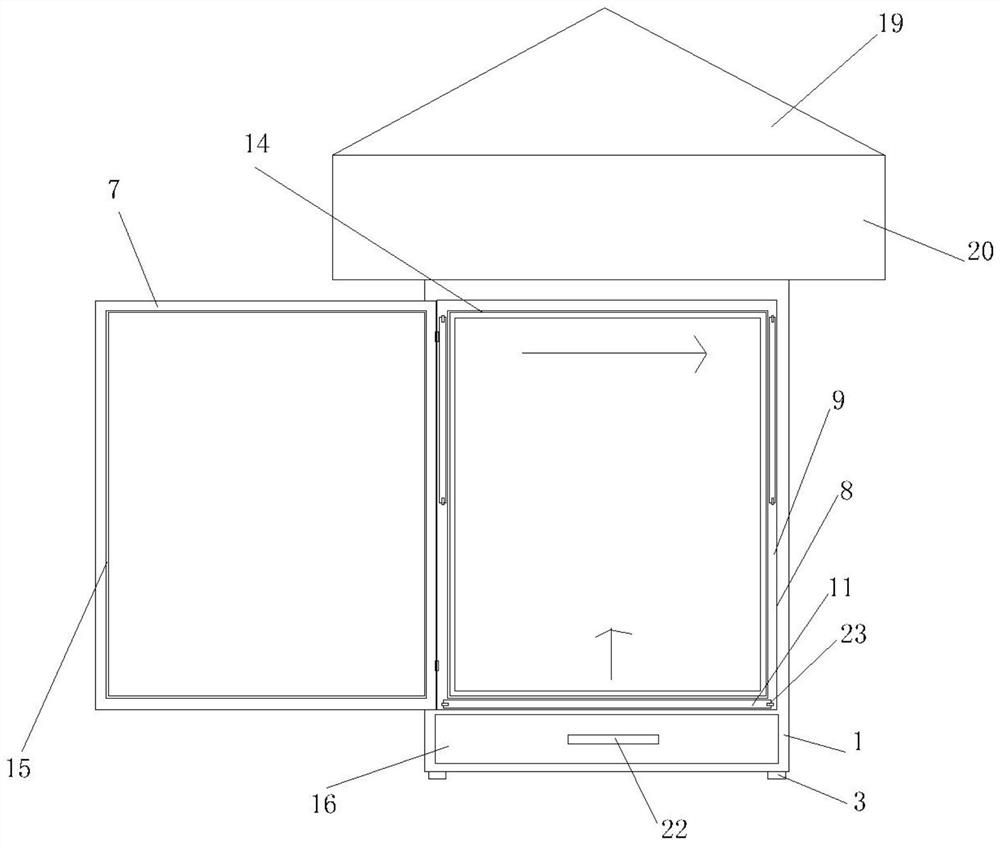

[0031] Such as figure 1 As shown, a protective structure of a switch cabinet includes a switch cabinet body 1 and a protective top cover 2. The bottom of the switch cabinet body 1 is provided with a pad 3, so that there is a gap between the bottom of the switch cabinet body 1 and the ground. distance for air circulation.

[0032] Such as Figure 1-Figure 4 As shown, the top of the protective top cover 2 is inclined, so that rainwater can slide down along the top of the protective top cover 2 without water accumulation.

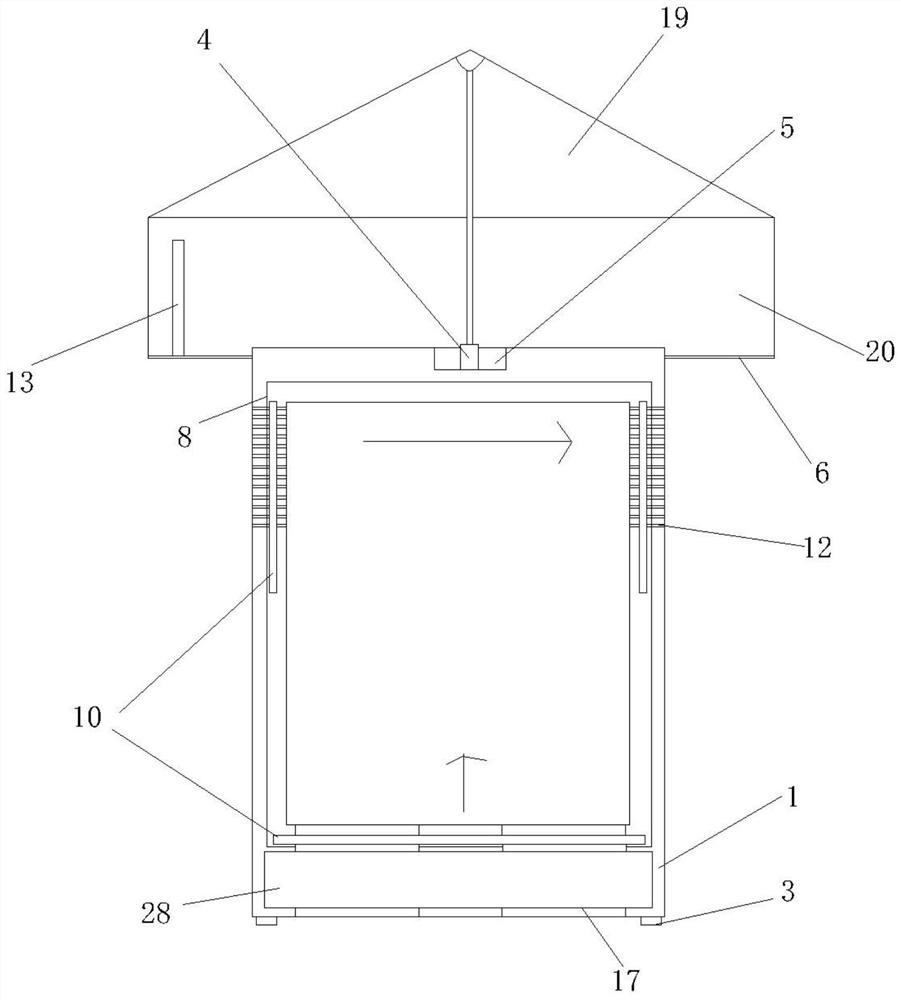

[0033] A cylinder 4 is connected between the top inner wall of the protective top cover 2 and the top wall of the switch cabinet body 1, and the cylinder 4 is used to drive the protective top cover 2 up and down. Installed on the bottom of the installation groove 5.

[0034] The bottom of the protective top cover 2 is provided with a bottom plate 6, and the bottom plate 6 is provided with an opening where the inner wall contacts the side of the switch cabin...

Embodiment 2

[0045] Such as Figure 1-Figure 5 As shown, compared with Embodiment 1, the protective top cover 2 of the present embodiment includes a top plate 19 and side baffles 20, and the top plate 19 includes two rectangular square top plates 19 and two triangular vertical top plates 19. Two vertical top boards 19 are arranged parallel to each other, the tops of the two square top boards 19 are connected, and the left and right sides of the square top board 19 are connected with the opposite sides of the two vertical top boards 19 respectively. down, to avoid water accumulation at the top of the protective top cover 2.

[0046] The top plate 19 is a triangular prism, and the side baffles 20 are arranged vertically. The top and bottom of the side baffles 20 are respectively connected to the bottom edge of the top plate 19 and the bottom plate 6. The four side baffles 20 are surrounded by the switch cabinet body 1. The bottom plate 6 is arranged horizontally.

[0047] When the cabinet ...

Embodiment 3

[0051] Such as Figure 1-Figure 6 As shown, compared with Embodiment 1, this embodiment is provided with fixed elastic pieces 23 on the steps 9 on both sides opposite to the accommodating cavity 10, one side of the fixed elastic pieces 23 is fixed on the step 9, and the other side of the fixed elastic pieces 23 It is opposite to the accommodating cavity 10 .

[0052] The side of the dustproof plate 11 opposite to the accommodating cavity 10 is provided with a clamping hole 27, and the inner wall of the fixed elastic piece 23 facing the accommodating cavity 10 is provided with a clamping column. When the dustproof plate 11 is completely placed in the accommodating cavity 10, The clamping column can be clamped in the clamping hole 27 .

[0053] When installing the dustproof plate 11, the side of the fixed elastic piece 23 facing the accommodation cavity 10 is pulled up so that it does not block the opening of the accommodation cavity 10, and the dustproof plate 11 is inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com