Vehicle-mounted jumper wire production process

A production process and jumper technology, which is applied in the field of vehicle jumper production technology, can solve the problems of inability to detect raw materials and low service life, and achieve the effects of convenient assembly, improved service life, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The production process of a vehicle-mounted jumper according to the present invention will be further described in detail below through specific embodiments.

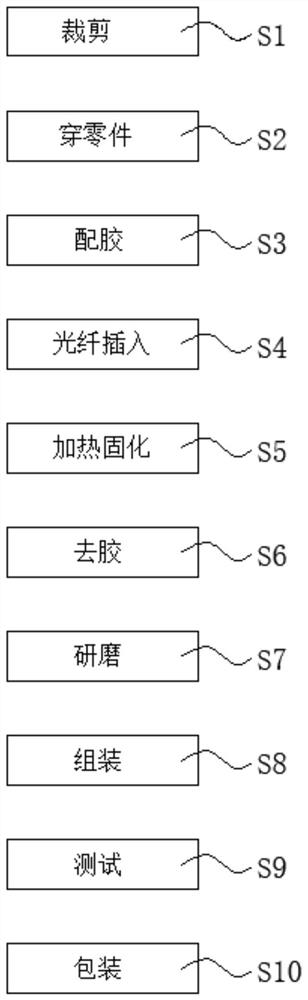

[0027] like figure 1 As shown, the present invention provides a technical solution: a production process for a vehicle-mounted jumper, comprising the following steps:

[0028] S1, cutting: mainly according to the needs, cut the length of the jumper to make it the same length, and then adjust it;

[0029] S2, wear parts: wear various loose parts to the optical fiber, and then wear the rubber sheath, heat shrinkable tube, support tube and spring in sequence;

[0030] S3. Glue: mix partA and partB in the optical glue in proportion to reduce foaming;

[0031] S4. Optical fiber insertion: peel off the outer skin of the optical fiber, then inject the adjusted glue into the tail handle of the ferrule with a glue dispenser, and then insert the optical fiber into the ferrule filled with glue;

[0032] S5, heating and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com