Nut anti-loosening structure and anti-loosening thread pair

A threaded pair and nut technology, applied in the direction of nuts, threaded fasteners, screws, etc., can solve the problems of high pressure resistance, corrosion resistance, rubber gaskets not resistant to high temperature, etc., and achieve the effect of increasing elasticity and solving corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

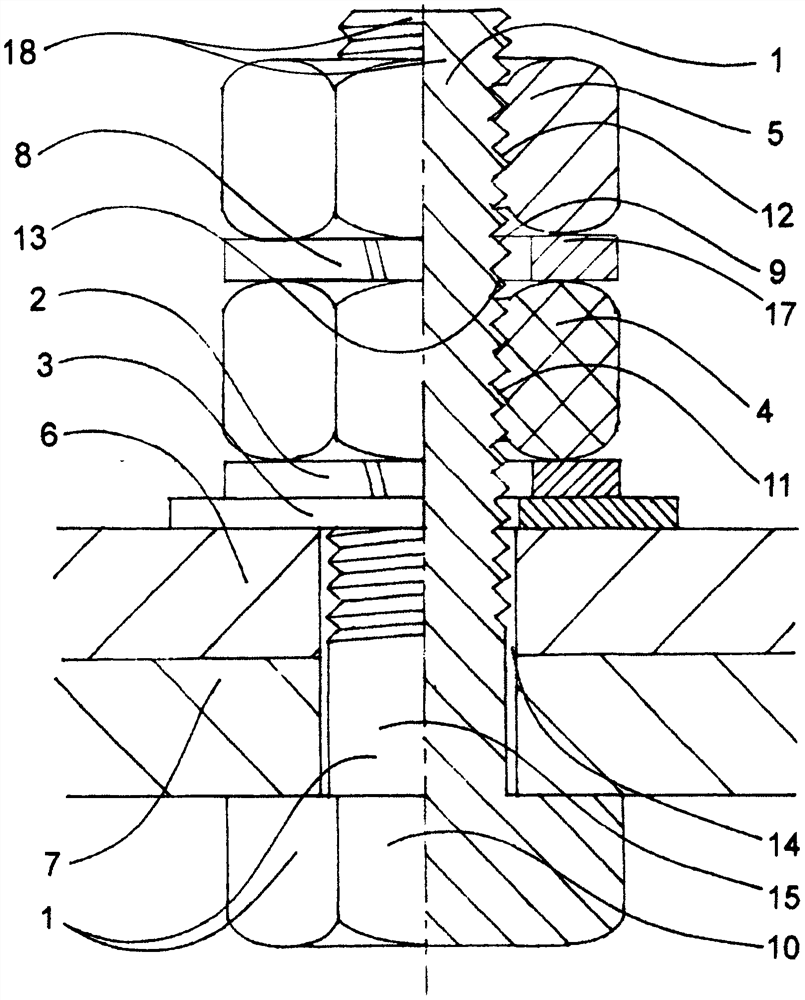

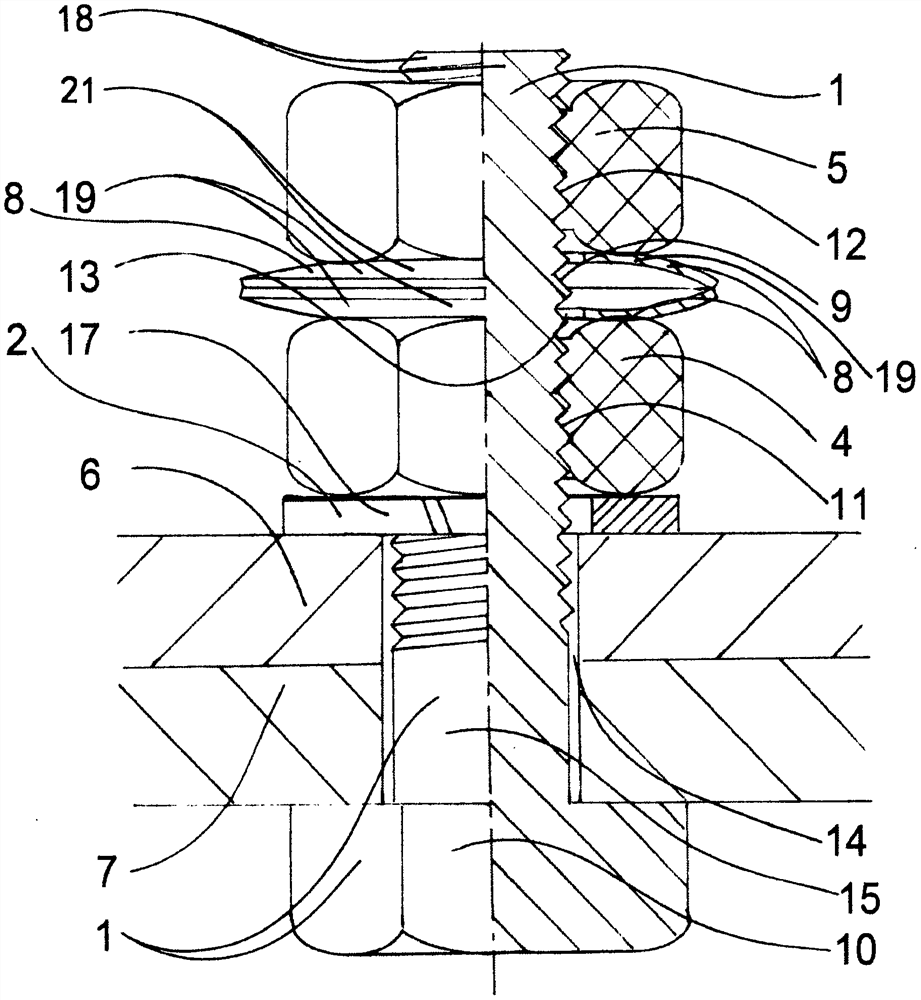

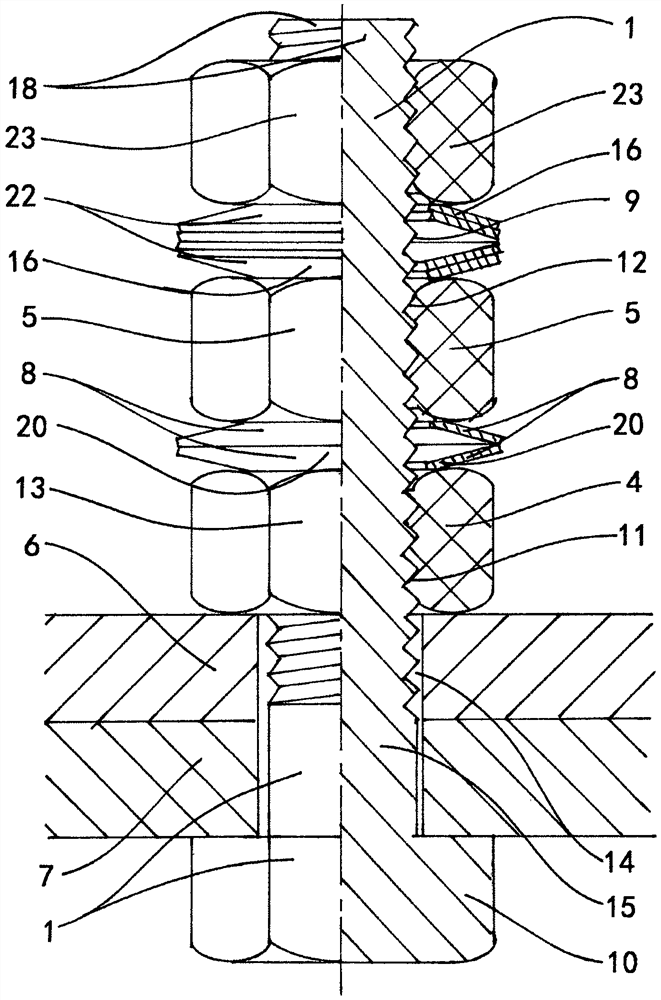

[0034] The present invention will be further described below in conjunction with the accompanying drawings:

[0035] The first aspect of the present invention relates to a nut anti-loosening structure, such as figure 1 shown in, including

[0036] Main nut 4, used for screwing on the fixed end of bolt 1,

[0037] The auxiliary nut 5 is used for screwing on the fixed end of the bolt 1, and is located outside the main nut 4,

[0038] The auxiliary washer 8, which is a metal washer, is used to be sleeved on the fixed end of the bolt 1, and is located between the main nut 4 and the auxiliary nut 5;

[0039] The auxiliary washer 8 is elastically deformed after the main nut 4 and the auxiliary nut 5 squeeze the auxiliary washer 8 . The auxiliary washer 8 is elastically deformed, so that the auxiliary washer 8 has elastic force on the main nut 4 and the auxiliary nut 5, and at the same time maintains the main nut 4, the auxiliary nut 5 and the auxiliary washer 8 to generate a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com