Extremely thick coal seam accurate danger relieving and yield increasing method based on directional drilling advanced high-pressure water injection

A technology for directional drilling and thick coal seam, which is applied in earth-moving drilling, wellbore/well components, dust prevention, etc., can solve the problems affecting the safety of roadway excavation construction and coal face mining construction, and achieve the effect of improving pressure relief and degree, strengthen the degree of pressure relief, reduce the effect of dust concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

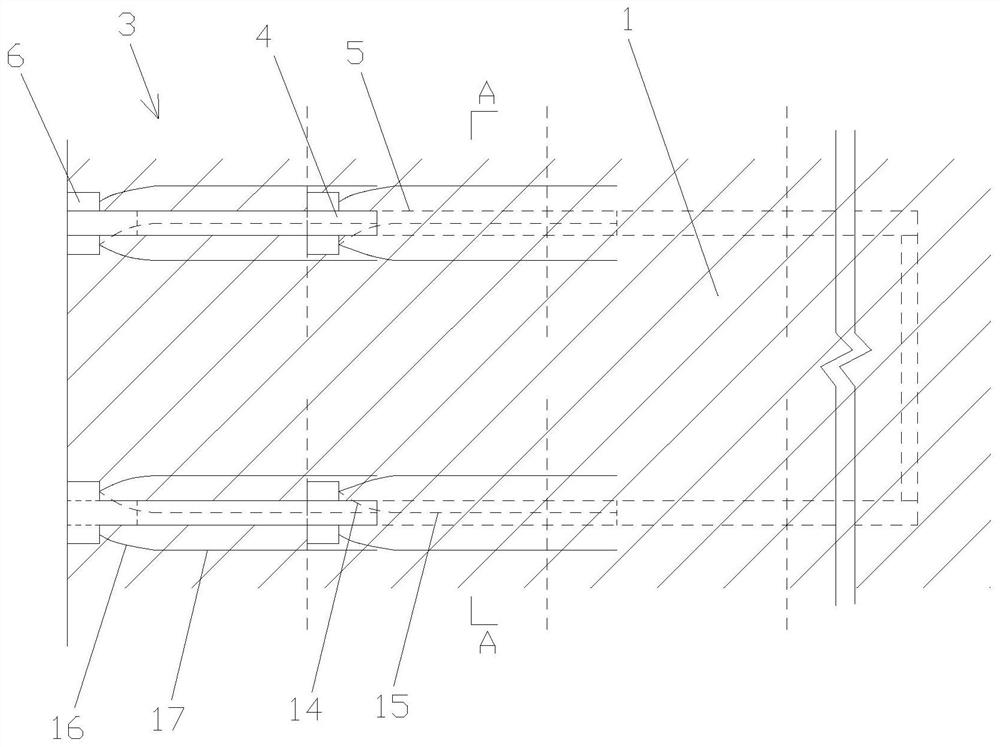

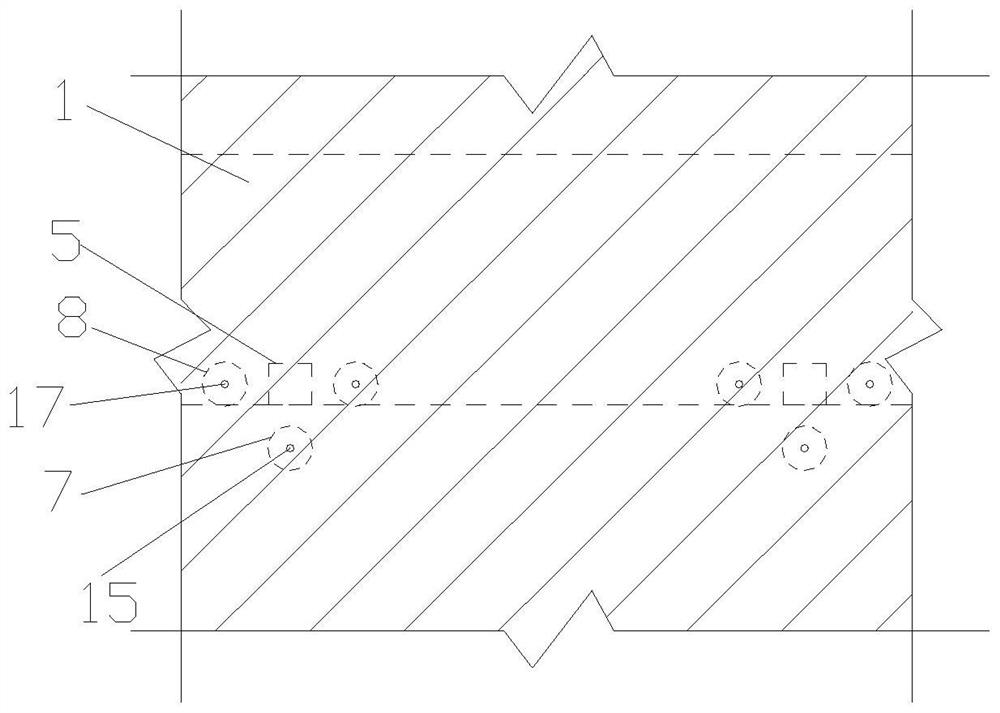

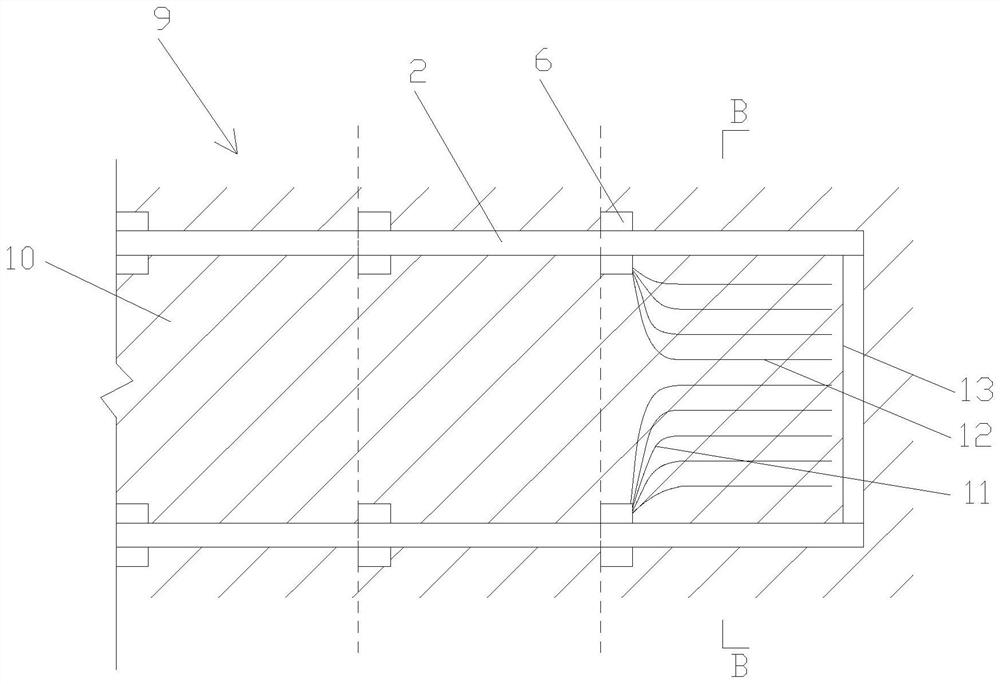

[0059] like Figure 1 to Figure 5 As shown in the present invention, the method for accurate risk resolution and production increase of huge thick coal seam based on directional drilling and advanced high pressure water injection is the same as the method for accurate risk resolution and production increase of top coal seam and middle coal seam. The construction method for precise crisis resolution and production increase includes the following steps:

[0060] Step 1. The pressure relief and excavation construction of the roadway:

[0061] The number of described roadways 2 is two, and the two roadways 2 are respectively an air inlet roadway and a return air roadway, and the pressure relief excavation construction method of the two roadways 2 is the same; the specific steps for any roadway 2 to carry out pressure relief excavation construction are as follows :

[0062] Step 101, dividing the roadway area to be constructed into a plurality of roadway sections 3 to be construc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com