Assembly type pipeline integrated partition wall structure of single-side corrugated tile plate

A corrugated board and assembled technology, which is applied in the field of assembled pipeline integrated partition wall structure, can solve the problems of pipeline card structure occupying indoor space, troublesome wiring and fixed structure, and large quality of strip partition wall, etc., and achieves simple structure , Easy to transport and install, satisfy the effect of nail holding force and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

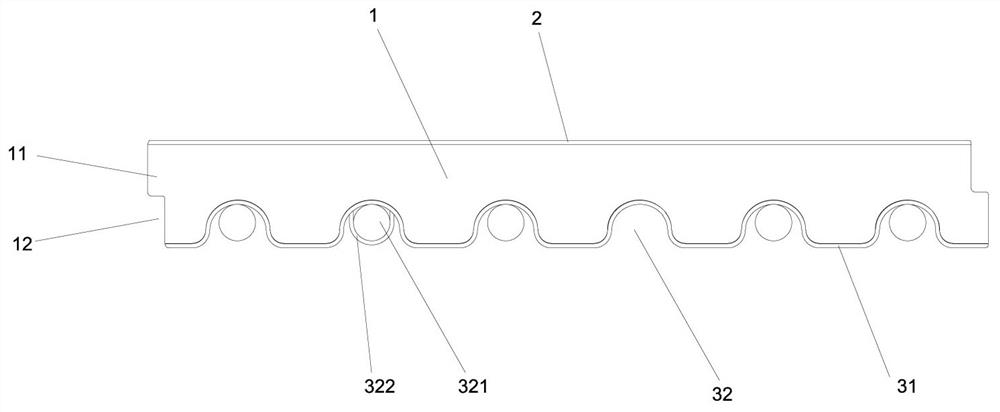

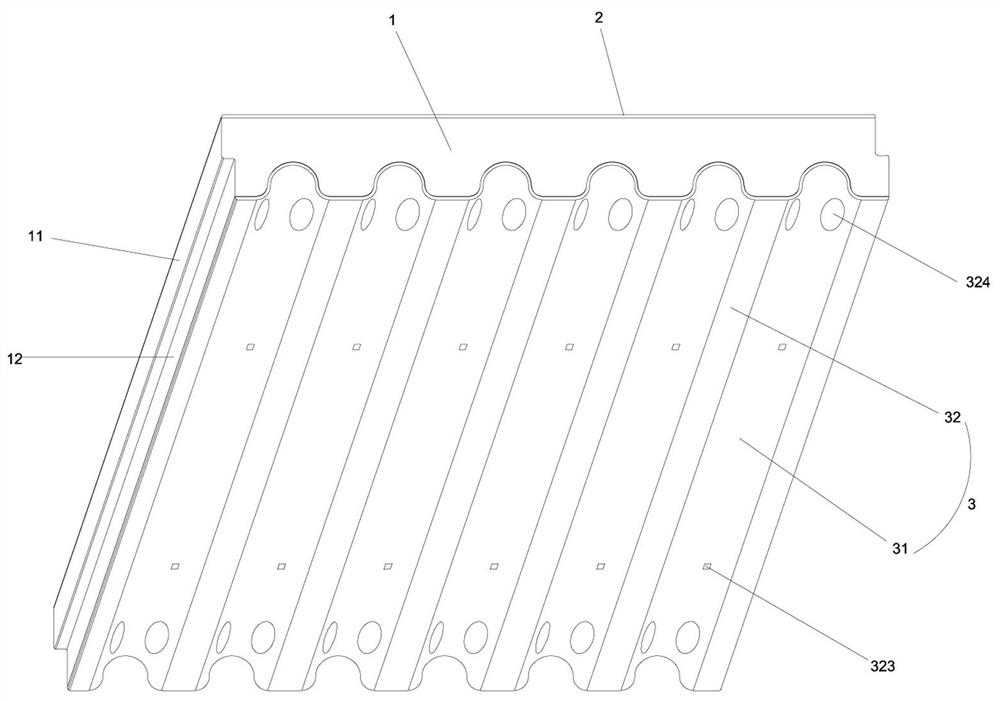

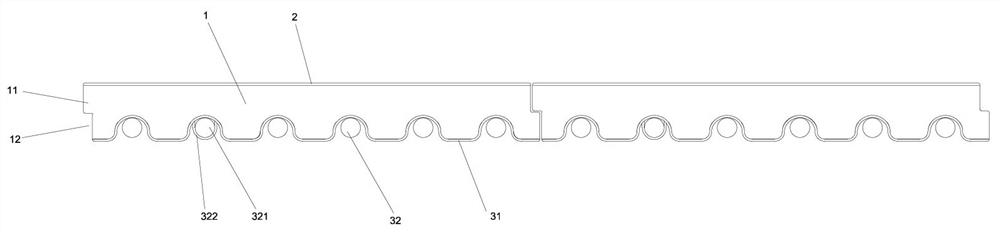

[0032] Example 1: as Figures 1 to 4 As shown, it is only one of the embodiments of the present invention, an assembled pipeline integrated partition wall structure of a single-sided corrugated board, comprising a central core board 1, a flat panel disposed on one side of the central core board 1 The panel 2 and the wave board 3 arranged on the side of the central core board 1 away from the plane board 2, the wave board 3 includes a main board body 31 and several parallel arranged on the main board body 31. The wave tile groove 32, the main board body 31 is arranged in parallel with the flat plate 2, the wave tile groove 32 is provided with a pipeline 321 and a limit card 322 for limiting the position of the pipeline 321, the central core Filling particles are arranged between the board 1 and the wave tile plate 3 and in the wave tile groove 32 .

[0033] In the present invention, the flat board 2, the wave board 3 and the core board 1 arranged between the flat board 2 and th...

Embodiment 2

[0040] Example two, as Figures 1 to 4 As shown, it is only one embodiment of the present invention. On the basis of the first embodiment, in the assembled pipeline integrated partition wall structure of the single-sided corrugated board of the present invention, the end of the central core board 1 The part is provided with a protrusion 11 and a groove 12 for facilitating the insertion of the protrusion 11, which can facilitate the connection of two adjacent partition walls, and the protrusion 11 of one core board 1 is just inserted into the other. In the groove 12 of the core board 1, the splicing of the partition board can be well completed.

[0041] Here, the protrusions 11 and the grooves 12 are both elongated, and the widths of the protrusions 11 and the grooves 12 are both half of the thickness of the core board 1; equivalent to the core board 1 The side of the wall forms a Z-shaped tongue and groove structure, and the splicing of the two partition panels is more conven...

Embodiment 3

[0044] Example three, as Figures 1 to 5 As shown, it is only one embodiment of the present invention. On the basis of any of the above-mentioned embodiments, in the prefabricated pipeline integrated partition wall structure of a single-sided wave tile plate of the present invention, the wave tile groove 32 The depth of the pipeline 321 is not less than the outer diameter of the pipeline 321, that is, the pipeline 321 will not protrude from the surface of the main board body 31 during installation, so as to ensure that the occupied space of the entire partition board will not become larger.

[0045] In addition, the limit card 322 is a U-shaped piece, and the bottom of the wave tile groove 32 is provided with a mounting hole 323 for facilitating the installation of the limit card 322, and both ends of the U-shaped piece can be inserted into the mounting hole 323 Inside, the fixing of the pipeline 321 is completed.

[0046] In addition, the side wall of the end of the wave til...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com