Plugging drainage device for dewatering well and construction method

A construction method and technology for drainage devices, which are applied in infrastructure engineering, construction, etc., can solve the problems of complex plugging procedures for dewatering wells, difficult to guarantee construction quality, and increase construction costs, so as to reduce groundwater seepage, save construction efficiency, The effect of strengthening the compressive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The embodiment of the present invention discloses a construction method for plugging drainage of a dewatering well, comprising the following construction steps:

[0043] Step 1: Backfill in the dewatering well and extract excess groundwater;

[0044] Step 2: Install the plugging sleeve 1 on the top of the dewatering well, and the plugging sleeve 1 is connected and fixed with the pouring belt through the water stop ring 11;

[0045] Step 3: install the first plugging steel plate 3 in the installed plugging sleeve 1, and continuously pump water into the dewatering well by the pumping pump 2 during the process of installing the first plugging steel plate 3;

[0046] Step 4: After installing the first plugging steel plate 3, remove the water pump 2, pour concrete in the upper area of the first plugging steel plate 3, and install the second plugging steel plate 4 on the top of the plugging sleeve 1;

[0047] Step 5: Check the air tightness of the bottom of the dewatering ...

Embodiment 2

[0049] On the basis of Example 1, increase:

[0050] The backfilling layer of the step 1 includes two layers, from bottom to top, the sandstone backfilling layer and the concrete pouring layer are respectively.

[0051] When installing the first sealing steel plate 3 in step 3, adjust the position and angle of the first sealing steel plate 3 through the adjusting rod 31 on the first sealing steel plate 3, and connect the first sealing steel plate 3 to the sealing steel plate 3 by spot welding. The plug sleeve 1 is connected and fixed.

[0052] In step 3, when the water pump 2 is continuously pumping water in the dewatering well, the air pressure inside and outside the dewatering well is balanced by opening the exhaust pipe 32 on the first blocking steel plate 3 .

[0053] After the first blocking steel plate 3 is installed in step 4, the tightness between the first blocking steel plate 3 and the blocking sleeve 1 is tested first.

[0054] In step 4, concrete is poured in the...

Embodiment 3

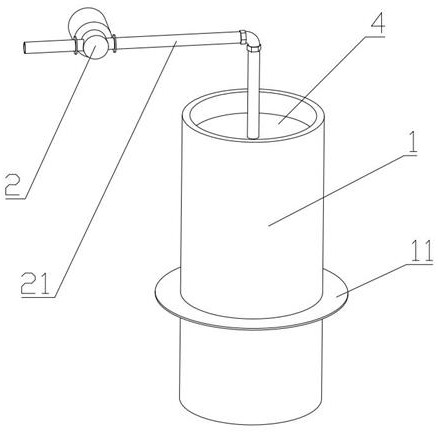

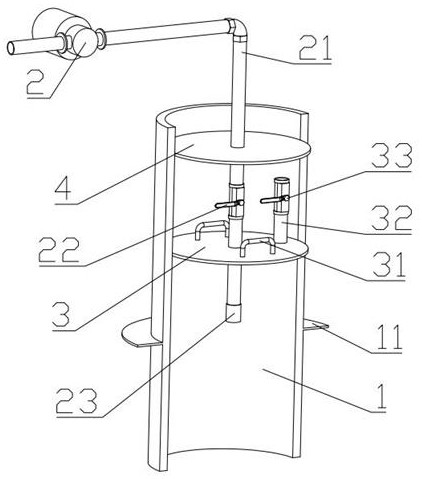

[0056] This embodiment provides a drainage well plugging and drainage device, refer to figure 1 and 2, including a plugging sleeve 1, which is characterized in that: a first plugging steel plate 3 is horizontally arranged in the plugging sleeve 1, a water stop ring 11 is arranged on the outer side of the plugging sleeve 1, and the A plugging steel plate 3 blocks the interior of the plugging sleeve 1 into a sealing area at the bottom and a filling area at the top. The sealing area is connected to the suction pump 2 through a water suction pipe 21, and the water suction pipe 21 is controlled by a water discharge valve 22 to open and block, An adjusting rod 31 is provided on the first blocking steel plate 3 .

[0057] The first blocking steel plate 3 is provided with an exhaust pipe 32 , and the exhaust pipe 32 is controlled by a vent valve 33 to open and resist.

[0058] A filter screen 23 is provided at one end of the water suction pipe 21 close to the sealing area.

[0059]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com