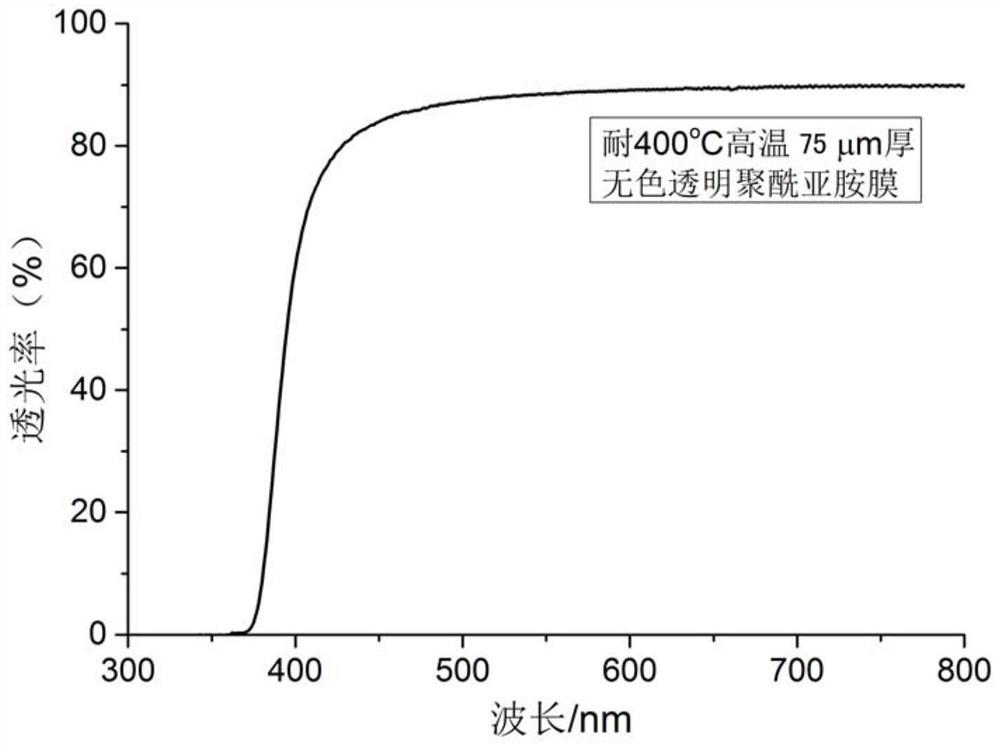

Colorless transparent polyimide film resistant to high temperature of 400 DEG C and preparation method thereof

A polyimide film, polyamic acid technology, applied in flat products, other household appliances, coatings, etc., can solve the problem of reduced device display accuracy, impact on display device quality and reliability, and poor optical alignment accuracy, etc. problem, to achieve the effect of wide application prospects and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The colorless transparent polyimide film resistant to high temperature of 400°C in this embodiment is completed according to the following steps:

[0025] 1. Add 150L of solvent: N,N-dimethylacetamide (DMAc) into the 300L dissolving kettle equipped with mechanical stirring and nitrogen inlet and outlet, and feed nitrogen. Four diamine monomers of FFDA, TFDB, FDA and FA are added to the dissolving kettle, and the molar ratio of the substances is FFDA:TFDB:FDA:FA=2:3:2:3; stir until completely dissolved to obtain a mixed two Amine solution; the volume ratio of diamine weight to aprotic polar solvent is 16Kg:150L.

[0026] 2. The mixed diamine solution in the dissolving kettle is all pressed into the 300L resin kettle equipped with mechanical stirring and nitrogen inlet and outlet through the pressure pump, and nitrogen is introduced. Then, 6FDA, BTDA, BPAF mixed dianhydride was added to the resin kettle in several times, and the ratio of the substances was 6FDA:BTDA:BPAF...

Embodiment 2

[0034] The colorless transparent polyimide film resistant to high temperature of 400°C in this embodiment is completed according to the following steps:

[0035] 1. Add 150L of N,N-dimethylformamide into the 300L dissolving kettle equipped with mechanical stirring and nitrogen inlet and outlet, and feed nitrogen. Four diamine monomers, FFDA, TFDB, FDA, and FA, were added to the dissolving kettle, and the molar ratio of the substances was FFDA:TFDB:FDA:FA=17:1:1:1; stirred until completely dissolved to obtain mixed two Amine solution; the volume ratio of diamine weight to aprotic polar solvent is 12.0Kg:150L.

[0036] 2. The mixed diamine solution in the dissolving kettle is all pressed into the 300L resin kettle equipped with mechanical stirring and nitrogen inlet and outlet through the pressure pump, and nitrogen is introduced. Then, 6FDA, BTDA, BPAF mixed dianhydride was added into the resin kettle in several times, and the ratio of the substances was 6FDA:BTDA:BPAF=16:2:2....

Embodiment 3

[0044] The colorless transparent polyimide film resistant to high temperature of 400°C in this embodiment is completed according to the following steps:

[0045] 1. Add 150LN-methylpyrrolidone to the 300L dissolving kettle equipped with mechanical stirring and nitrogen inlet and outlet, and feed nitrogen. Add FFDA, TFDB, FDA, FA four diamine monomers into the dissolving kettle, and the molar ratio of the substances is FFDA:TFDB:FDA:FA=1:17:1:1; stir until completely dissolved to obtain a mixed two Amine solution; the volume ratio of diamine weight to aprotic polar solvent is 13Kg:150L.

[0046] 2. The mixed diamine solution in the dissolving kettle is all pressed into the 300L resin kettle equipped with mechanical stirring and nitrogen inlet and outlet through the pressure pump, and nitrogen is introduced. Then, 6FDA, BTDA, BPAF mixed dianhydride was added to the resin kettle in several times, and the ratio of the substances was 6FDA:BTDA:BPAF=3:14:3. The molar ratio of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com