Electric vehicle platform expansion structure without battery pack shell

An electric vehicle, battery-free technology, applied in the direction of electric vehicles, substructure, electric power devices, etc., can solve the problems of poor scalability, low applicability, high cost, etc., to save development costs, reduce body weight, improve The effect of generalization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions and advantages of the invention clearer, the invention is further described below with reference to the accompanying drawings.

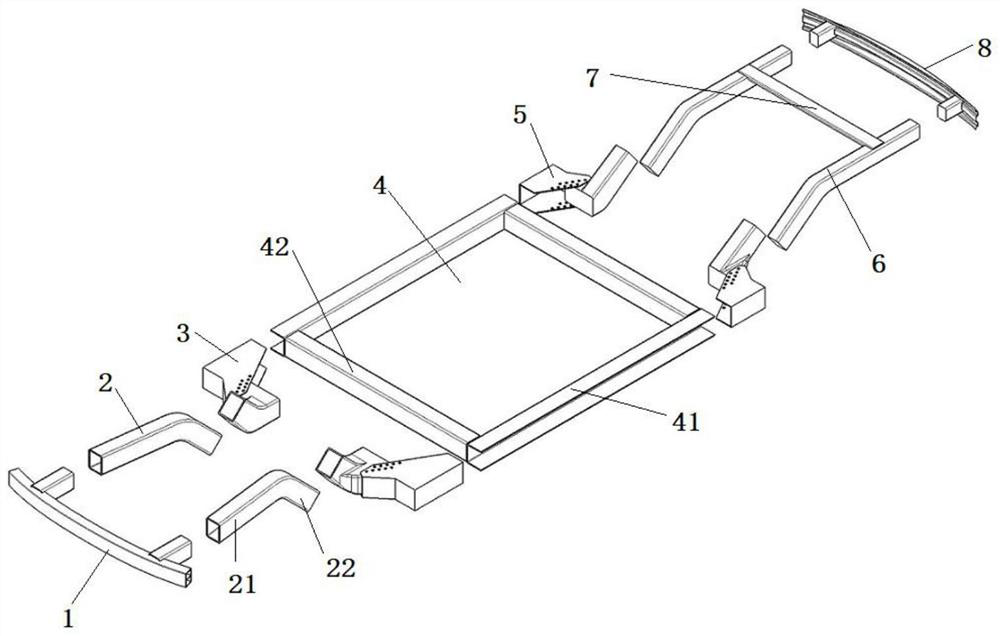

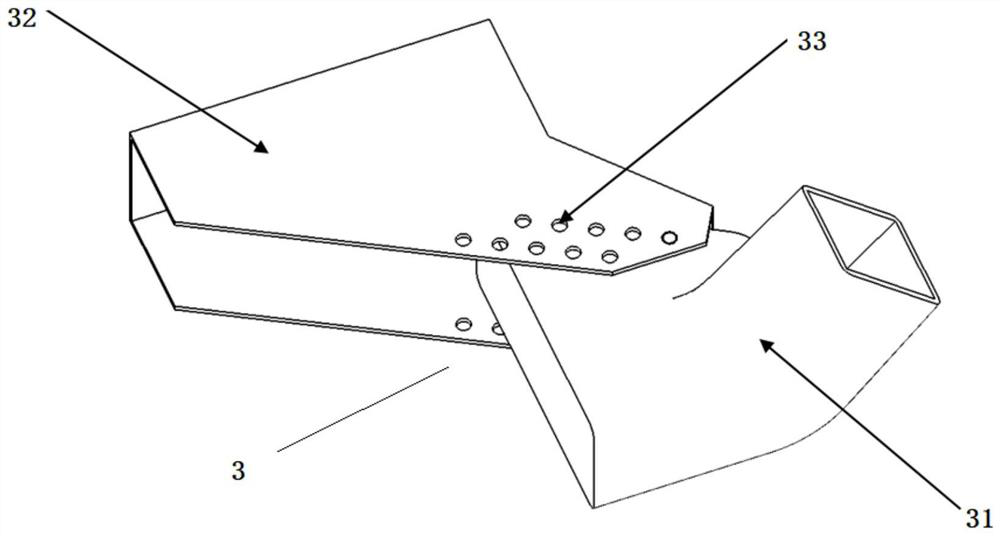

[0030] like figure 1 As shown, an electric vehicle platform expansion structure without a battery pack shell includes a front anti-collision beam 1, two front longitudinal beams 2, two front variable longitudinal beam connection modules 3, a middle vehicle body battery frame 4, two A rear variable longitudinal beam connection module 5 , a rear longitudinal beam 6 , a rear floor cross beam 7 , and a rear anti-collision beam 8 .

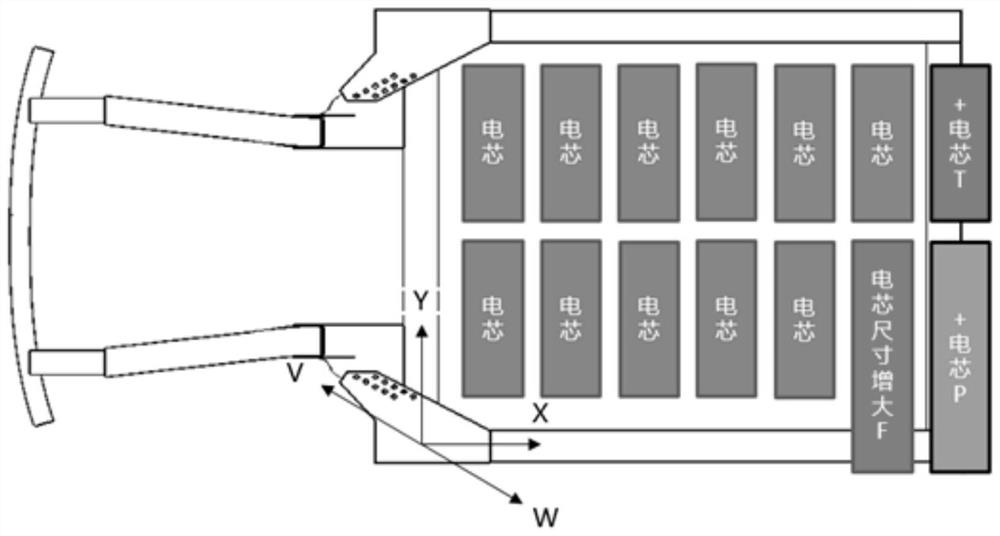

[0031] When the size and battery power of the electric vehicle are expanded, the arrangement of the front and rear motors and their related accessories is generally not changed. Therefore, in the present invention, the front anti-collision beam 1, the rear longitudinal beam 6, the rear floor beam 7, and the rear anti-collision beam 8 are maintained. Existing design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com