Urea-formaldehyde-resin-based crease-resistant finishing method for high-density and high-count cotton textile

A technology of anti-wrinkle finishing and urea-formaldehyde resin, which is applied in textiles and papermaking, fiber treatment, plant fiber, etc. It can solve the problems of anti-wrinkle technology such as complex process, low efficiency, and high production cost, and achieve good mechanical properties, facilitate diffusion, and improve swelling sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In Example 1, R 1 It is a polysiloxane chain unit with a molecular weight of 1500, R 2 It is a polysiloxane chain unit with a molecular weight of 1500, R 3 It is a polyethylene glycol chain link with a molecular weight of 2000.

Embodiment 2

[0083] In Example 2, R 1 It is a polysiloxane chain unit with a molecular weight of 2000, R 2 is a polyethylene glycol chain segment with a molecular weight of 1500, R 3 It is a polyethylene glycol chain link with a molecular weight of 1500.

Embodiment 3

[0084] In Example 3, R 1 It is a polysiloxane chain unit with a molecular weight of 2500, R 2 is a polyethylene glycol chain segment with a molecular weight of 2000, R 3 It is a polyethylene glycol chain link with a molecular weight of 2000.

[0085] The cotton fabrics used in the following examples and comparative examples are high-density and high-count cotton fabrics (specification 130*8080 / 2*80 / 2).

[0086] Example 1

[0087] (1) One-time padding: the cotton fabric is subjected to padding treatment in the configured anti-wrinkle finishing bath, and the anti-wrinkle finishing agent is transferred to the fiber surface;

[0088] (1.1) deionized water padding is performed on the cotton fabric, and the nip rate is controlled to be 45%;

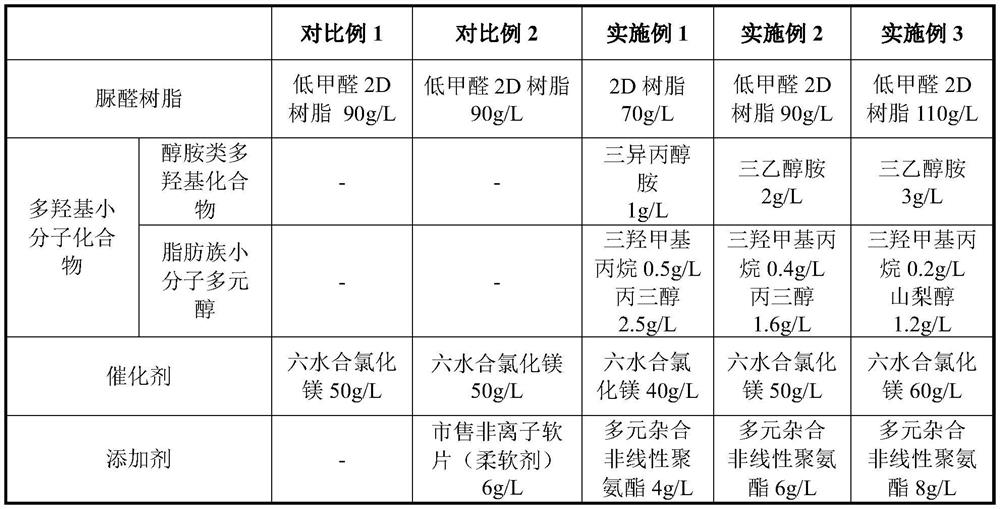

[0089] (1.2) add urea-formaldehyde resin, catalyst, alcohol amine polyhydroxy compound, aliphatic small molecule polyol to the metered deionized water and fully stir and dissolve to obtain an anti-wrinkle finishing bath (see Table 1 for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com