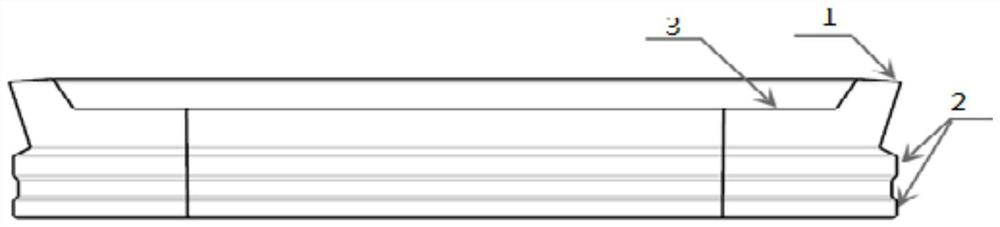

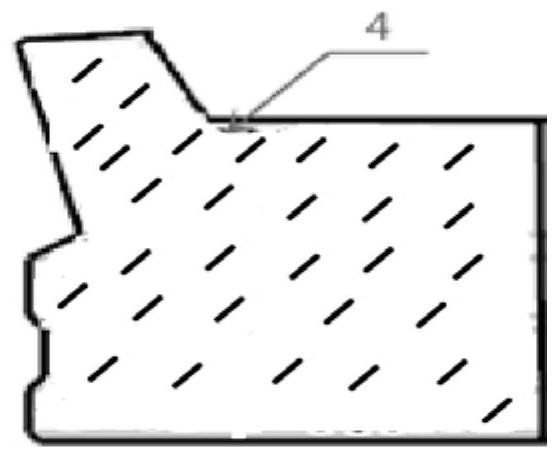

Self-repairing polyurethane concrete piston head and preparation method thereof

A polyurethane and self-repairing technology is applied in the field of self-repairing polyurethane concrete piston head and its preparation, which can solve the problems of easy scratches and wear, short life, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a self-repairing polyurethane concrete piston head comprises the following steps:

[0037] (1) Weigh in parts by weight 30 parts of MDI50, 80 parts of PPG1000, 40 parts of BDO, 60 parts of chain extender, 15 parts of BME, and 8 parts of defoamer;

[0038] (2) PPG was added to the three-necked flask, heated and stirred in an oil bath, and the temperature was slowly raised to 110~120°C. Then vacuum dehydration for 1.5h, keeping the vacuum degree at -0.01Mpa. Cool to 50~60℃, add MDI and react for 1h. Continue to heat to 80°C for 3 hours to obtain polyurethane component A, which is sealed and stored;

[0039] (3) Put the chain extender, BDO, BME, and defoamer in the bucket, stir for 10 minutes, vacuumize and remove foam for 10 minutes, and keep the vacuum degree at -0.01 Mpa to obtain the polyurethane component B, which is sealed and stored;

[0040] (4) Add 3000g of polyurethane A component to tank A of the pouring machine, control the temperatur...

Embodiment 2

[0047] (1) Weigh 40 parts by weight of MDI100, 90 parts of PPG2000, 45 parts of BDO, 60 parts of chain extender, 10 parts of BME, and 6 parts of defoamer;

[0048] (2) PPG was added to the three-necked flask, heated and stirred in an oil bath, so that the temperature was slowly raised to 100~110°C. Then vacuum dehydration for 2h, keeping the vacuum degree at -0.01Mpa. Cool to 50~60℃, add MDI and react for 1h. Continue to heat to 70°C for 4 hours to obtain polyurethane component A, which is sealed and stored;

[0049] (3) Put the chain extender, BDO, BME, and defoamer in the bucket, stir for 10 minutes, vacuumize and remove foam for 10 minutes, and keep the vacuum degree at -0.01 Mpa to obtain the polyurethane component B, which is sealed and stored;

[0050] (4) Add 3000g of polyurethane A component into the A tank of the casting machine, control the temperature at 90°C, and stir at a medium and low speed at 650rpm;

[0051] (5) Add 500g of polyurethane component B into the...

Embodiment 3

[0057](1) Weigh 50 parts by weight of MDI50, 100 parts of PPG2000, 50 parts of BDO, 70 parts of chain extender, and 10 parts of defoamer;

[0058] (2) PPG was added to the three-necked flask, heated and stirred in an oil bath, so that the temperature was slowly raised to 100~1120°C. Then vacuum dehydration for 2h, keeping the vacuum degree at -0.01Mpa. Cool to 50~60℃, add MDI and react for 1h. Continue to heat to 90°C for 3 hours to obtain polyurethane component A, which is sealed and stored;

[0059] (3) Put the chain extender, BDO and defoamer in the bucket, stir for 10 minutes, vacuumize for 10 minutes, and keep the vacuum degree at -0.01 Mpa to obtain the polyurethane component B, which is sealed and stored;

[0060] (4) Add 3000g of polyurethane A component into the A tank of the casting machine, control the temperature at 90°C, and stir at a medium and low speed at 650rpm;

[0061] (5) Add 500g of polyurethane component B into the B tank of the pouring machine, and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com