Quick and stable cooling and emptying method for double-chamber kiln

A double-chamber kiln and fast technology, applied in the field of double-chamber kilns, can solve the problems of the double-chamber kiln being difficult to rapidly cool down, unable to discharge materials uniformly and stably, achieve rapid emptying, realize uniform and stable discharge, and control the air intake volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

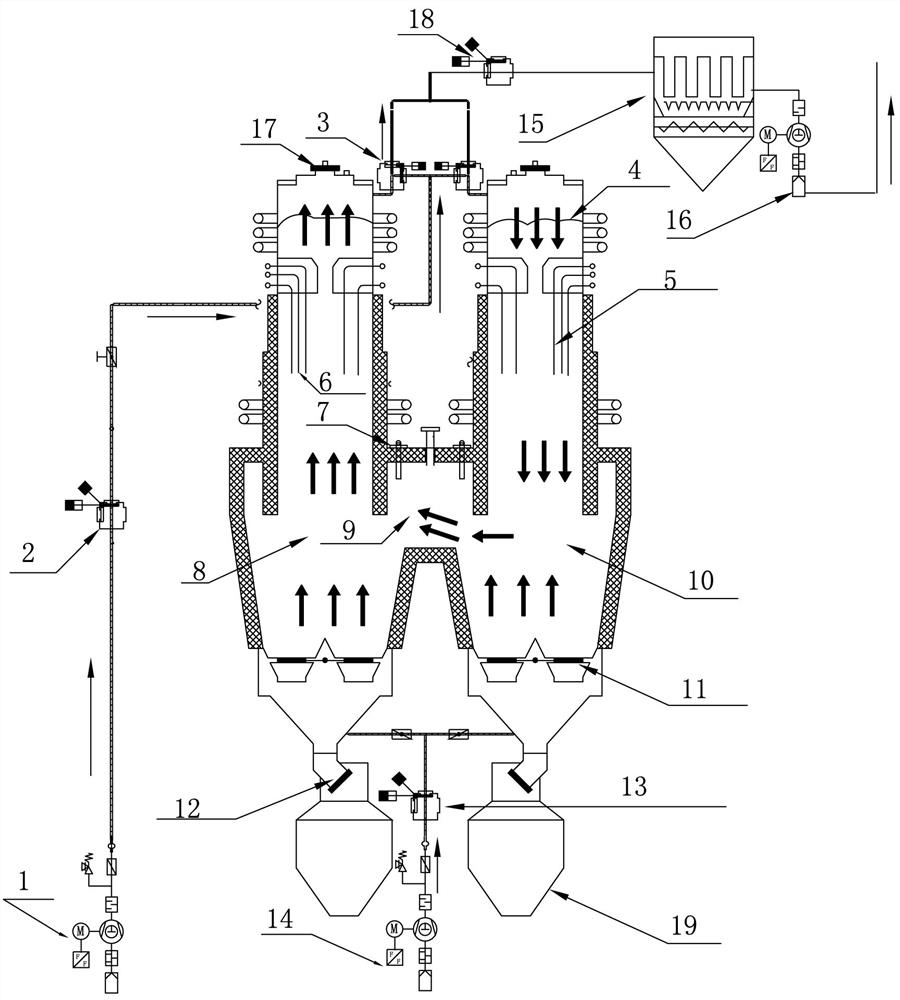

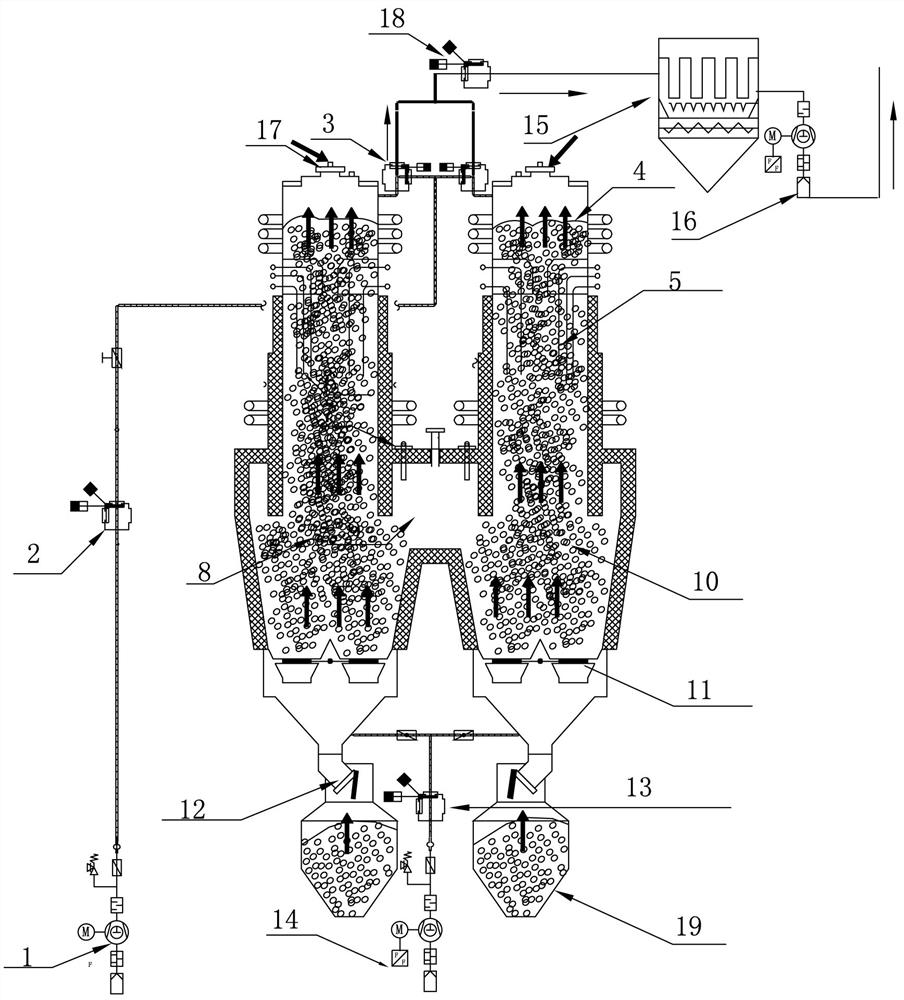

[0023] Below in conjunction with accompanying drawing embodiment, the present invention is described in further detail:

[0024] like figure 1 and figure 2 As shown in the figure, each kiln chamber of the double-chamber kiln has a discharge platform 11, and each discharge platform 11 is provided with four ash discharge plates, and the ash temperature measurement point is set on the positive side of each ash discharge plate of the discharge platform 11. 150-200mm above; the exhaust gas temperature measurement point is set in the connecting pipe between one of the combustion-supporting air reversing valve 3 and the chimney reversing valve 18, and the distance between the exhaust gas temperature measuring point and the combustion-supporting air reversing valve 3 is 0.4~1m , preferably, the temperature measurement point of the exhaust gas can be set at the middle position of the connecting pipe between the combustion air reversing valve 3 and the chimney reversing valve 18 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com