Gear defect visual detection method and system based on improved YOLOv5 network

A visual detection and defect detection technology, applied in neural learning methods, biological neural network models, instruments, etc., to achieve the effect of accurate detection and recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

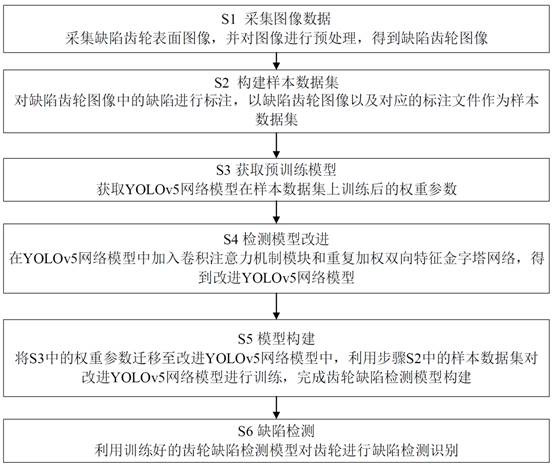

[0043] like figure 1 As shown, the present invention provides a visual detection method for gear defects based on an improved YOLOv5 network, comprising the following steps:

[0044] S1. Collect image data: collect the surface image of the defective gear, and preprocess the image to obtain the image of the defective gear;

[0045] S2. Build a sample data set: mark the defect types in the defective gear image and use it as a label, and construct a sample data set of the defective gear with the defective gear image and the corresponding label;

[0046] S3. Obtain the pre-training model: Use the sample data set obtained in step S2 to train the YOLOv5 network model (YOLOv5s network model), and obtain the weight parameters of the YOLOv5 network model;

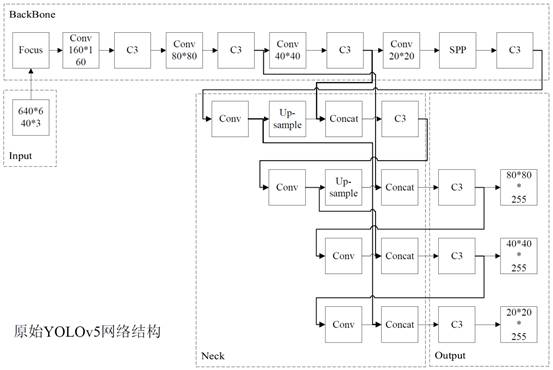

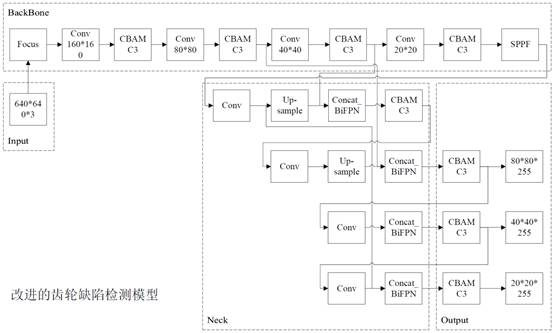

[0047] S4. Detection model improvement: The YOLOv5 network model is improved by adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com