Pipeline vibration reduction grillwork based on metal rubber and working method of pipeline vibration reduction grillwork

A metal rubber and grid technology, applied in the direction of pipeline supports, pipe components, pipes/pipe joints/fittings, etc., can solve problems such as accelerated pipeline wear, medium leakage, and vibration caused by hose flow, and achieve the solution of transmission medium leakage, Avoid fretting contact wear and reduce the effect of flow-induced vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above-mentioned features and advantages of the present invention easier to understand, the following specific embodiments are given and the accompanying drawings are described in detail as follows, but the present invention is not limited thereto.

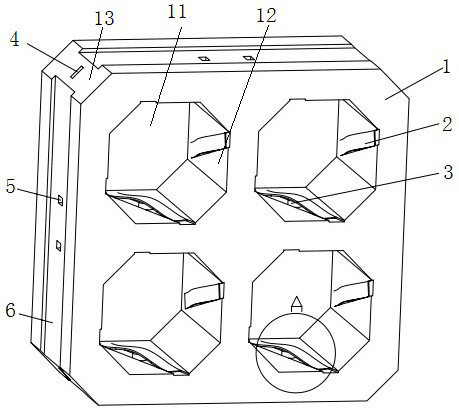

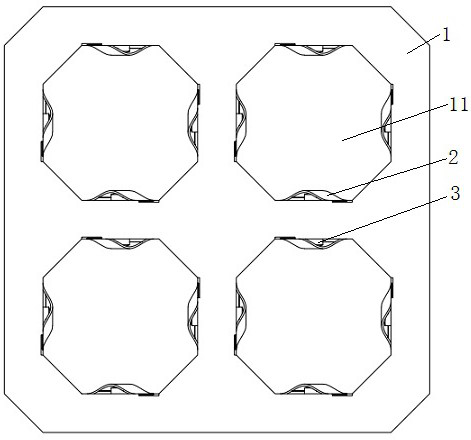

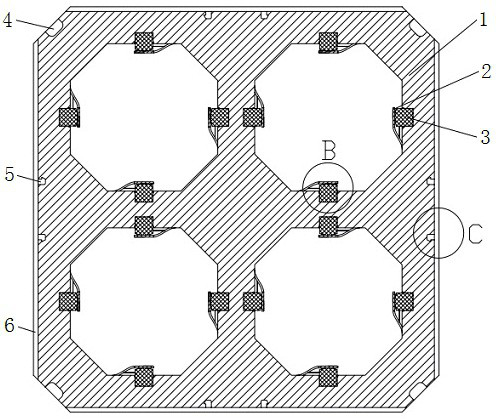

[0029] refer to Figure 1 to Figure 10

[0030] A metal-rubber-based pipeline vibration-damping grid, including a square grid 1, the square grid has a plurality of octagonal through holes 11 arranged in a neat array, and the octagonal through holes are spaced apart in pairs. The rectangular plane 12 on one side is provided with elastic sheets 2, the elastic sheets are convex, and one end is connected with the square frame, and the other end is the free end that can freely expand and contract when compressed by vibration. The rectangular plane where the elastic sheet is located in the through hole is mounted with a metal rubber 3 in contact with the lower surface of the elastic sheet. Metal rubber has g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com